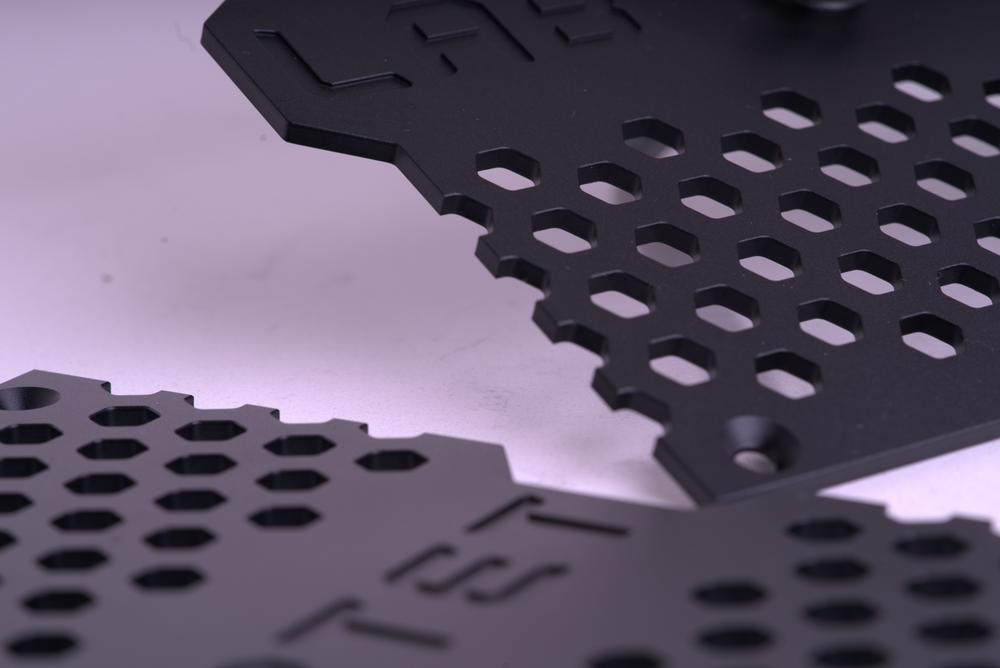

-

Posts

98 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Shawn

-

Thanks for the report. May I ask if you are using a GRHV supply? And is your transformer secondary around 330 VAC for the ±400 V rails? I just want to rule out whether my drop is caused by insufficient transformer headroom rather than the current limit itself.

-

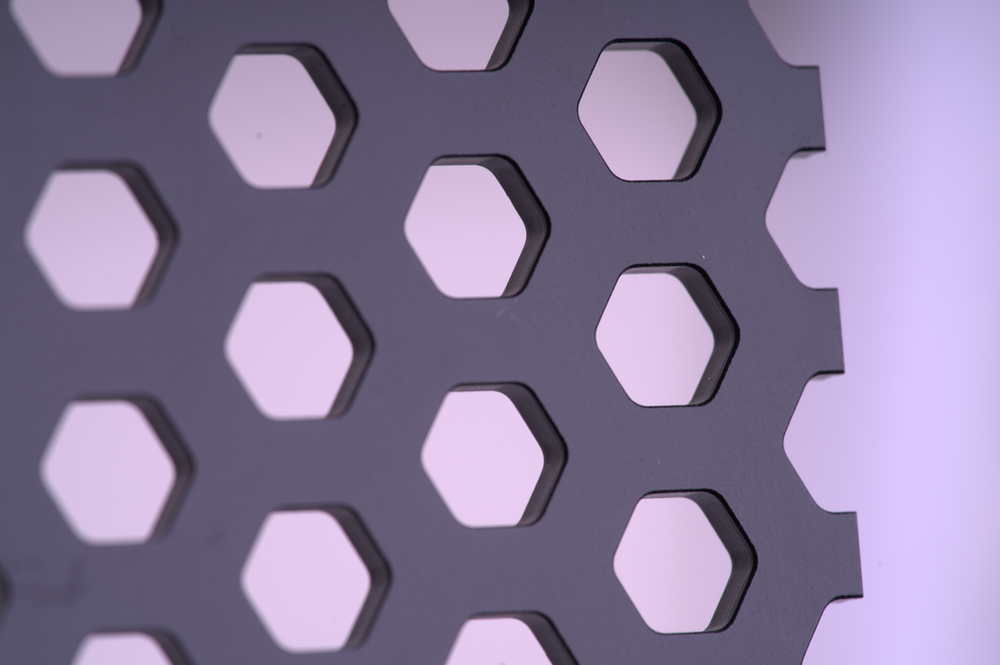

Thanks a lot for the hint. Since I haven’t ordered the test resistors yet, I’ll probably need some time before I can try it out on a new build. But for today I did some measurements on the current operating point, and hopefully these numbers help add to the pool of data. For easy comparison, I’ll use your same format. Based on the WE datasheet, I think both of our Vgk values are on the shallow side, but as Kevin has mentioned, modern 300Bs vary a lot, so I’m not 100% sure if this is correct. It might make sense to raise the current to 33–34 mA, in which case the required Vgk would move down (according to the WE300B datasheet, Vgk at 34 mA / 400 V is about –90 V). My expectation is that as the current goes up, the offset also increases and Vgk becomes more negative. To bring the offset back to 0 V, you’d adjust Vg, but when Vg changes, Vgk may swing more positive again. If possible, it would be great if you could validate this in LTspice. One more observation: with ±400 V supply, under load I measured about 389 V. I’m not sure if this is simply normal drop or if my current-limit is engaging. Could you let me know if your ±400 V rails drop as well? If yours stay right at 400 V, then I probably need to tweak my current-limit detection resistors.

-

Thanks for your reply. I plan to test different combinations of static current and cathode resistor values to better understand how they interact. If I get some results I’ll come back and share them. For now, I’m planning to try around 27–30 mA of static current. It’s a bit difficult to find high-precision resistors around 1.2 kΩ, so on the cathode side I’ll probably increase to about 8 kΩ and see how it behaves.

-

About the pin choice. I think this one might be closer to the original tube pins: MPN:6835-0-00-15-00-00-44-0 https://www.mouser.com/datasheet/2/273/MMMC_S_A0004813843_1-2556643.pdf I haven’t ordered it yet to confirm, but maybe it helps you. Also, I’d like to get your advice: At 400 V / 22 mA, would you consider setting Vgk around –95 V a good operating point? I’m also thinking about increasing the static current to around 27–30 mA. From what I see, the EL34 max plate dissipation is ~25 W. At 400 V / 30 mA, that’s only about 12 W, so it looks safe on paper. I’d love to hear your thoughts on this.

-

Yes, I noticed that too. But I found those machining marks only on the inner rear panel, left and right sides. The rest of the chassis looks clean. I’m pretty sure they just used 3-axis machining, which is still miles better than what I could do on my home-garage CNC. Of course, 5-axis is another story, and I’ve been thinking about designing some more complex curved surfaces where 5-axis paths would actually make sense. Overall though, I’m quite happy with how this chassis turned out. I haven’t yet checked all the PCB mounting hole positions against the boards, but so far it looks promising.

-

I’m up here at 12,000 feet, eating a bagel while tweaking my amp. Altimeter says it’s all good.🤞 And you know what, if you’re interested, I actually have an upcoming spare CNC chassis set (one PSU case and one amp case). I’d be more than happy to send it your way just for fun, freely. Let me know your thoughts.

-

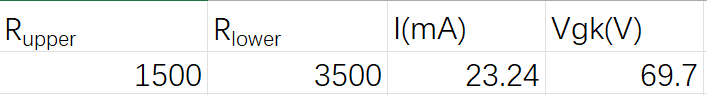

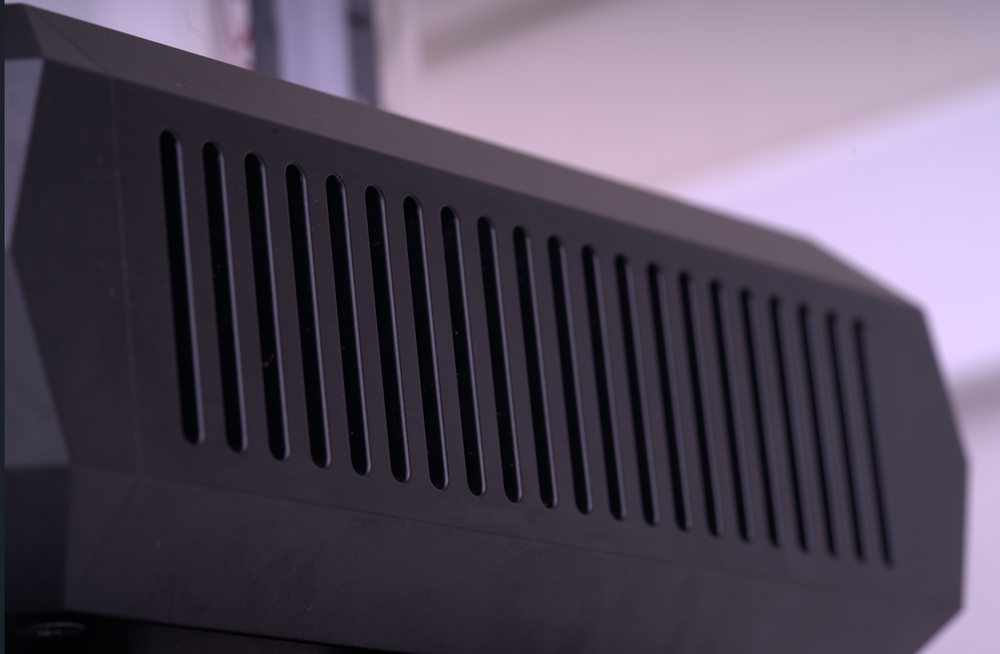

In the past few months, I haven’t been idle. Besides finishing a T2 Mini, I also continued to refine the GG chassis design. Through these experiences learning 3D design, I decided to completely re-draw the CAD files and hand them to a professional factory for prototyping (yes, I don’t believe a hobbyist garage CNC can really handle this job☹️). Below are some photos of the sample unit. This time the chassis is fully CNC-machined, which is why you can see the extremely thick panels and the more complex geometric structures compared to earlier versions. The side heatsinks are not separate parts. They are directly CNC machined into the chassis walls. At the same time, the bottom cover is split into two independent left and right plates, each with a grid-style cutout design. You can remove only one side of the bottom cover to do testing or adjustments without disturbing the entire chassis. The grid pattern reduces weight while maintaining mechanical strength, and it also improves ventilation inside the chassis. More updates will follow soon.

-

I actually kept the trimmers on the back side of the board. The PCB is mounted upside down near the top of the chassis, and I didn’t drill dedicated holes in the top cover for adjusting the trimmers. So each time I need to fine-tune them, I just tilt the whole chassis on its side and yes a bit inconvenient, but still manageable. A better solution would definitely be to make access holes in the top panel.

-

Paralleling a 3.3k resistor with the original 1.5k gave an effective resistance close to 1k, which I expected to behave similarly to using a single 1k resistor. After doing that, the offset increased significantly from around +12V to about +60V. So in the end, I reverted back to the original 1.5k setting resistor.

-

Thanks for the correction. I actually paralleled a 3.3k resistor with the existing 1.5k CCS set resistor, which gives an effective resistance of around 1031Ω. Based on the measured voltage drop, that gives me roughly 24–25mA of current. I believe the difference might come from my cathode resistor and grid voltage setup — possibly the cathode current is already limited before reaching the CCS. That might be why the current didn’t rise as much as expected even with the lower set resistor.

-

Quick update: it’s 6 AM here in California and I just wrapped up some late-night tweaking. Someone PM’d me earlier asking how I solved the offset and balance issue, and I can finally say: done. Offset is now around 0.3V and balance is about 0.2V. If anyone else is running into similar issues, here’s what worked for me: 1.CCS Set Resistor: I kept the CCS set resistor at 1.5k, which gives around 22–23mA static current. You can try lowering to 1k if you want around 25mA, but I found 1.5k sufficient. The more plate current you have, the higher the offset you will get. 2.Cathode Resistor: Changed from 3300Ω to 7k–7.5k. A larger cathode resistor gives you a deeper grid voltage. I could only find suitable 7k wirewound resistors on Mouser – they’re a bit bulky but still fit. Note: Larger values will increase the offset, so some trial and error is expected. 3. Grid Pot: I replaced the 10k pot with a 50k, which gave me a much wider range to trim both offset and balance. Final bias: around 24–25mA static current, Vgk ≈ -75V. Hopefully, this helps anyone else dialing in the Megatron XL and happy tweaking!😊

-

A quick update on this build. Regarding the low-frequency distortion at high volume that I mentioned earlier, I did some troubleshooting. First, I checked the GRHV output for the +300 V rail. It's extremely stable and consistently holds at 300 V, so it doesn’t seem like any current limiting is kicking in. By chance, I noticed that the D3 LED (next to the 2SA1968 and I'm using STN9360 in this spot) flashes during loud low-frequency passages. That seems to suggest the current mirror may be going into over-saturation. This might be related to the two 150 kΩ resistors labeled R8A101 and R8B101 in the schematic. In the original Megatron, there is actually just a single 150 kΩ pull-down resistor instead of two. That difference might be causing the issue. Also measured the anode voltage of the 12AX7 tied to the current mirror. Under loud, bass-heavy signals, it shows a clear voltage drop from about 355 V down to 345 V momentarily. I’m planning to try shorting one of the 150 kΩ R8 resistors to see if that improves things. Updated: Turns out the current mirror itself was fine. The culprit was actually one of the PSVANE 12AX7 tubes. I suspect there may be a reason these were on sale at TubeDepot. At least the one I got had issues under load. Anyway, swapped it out and the problem is now completely resolved.

-

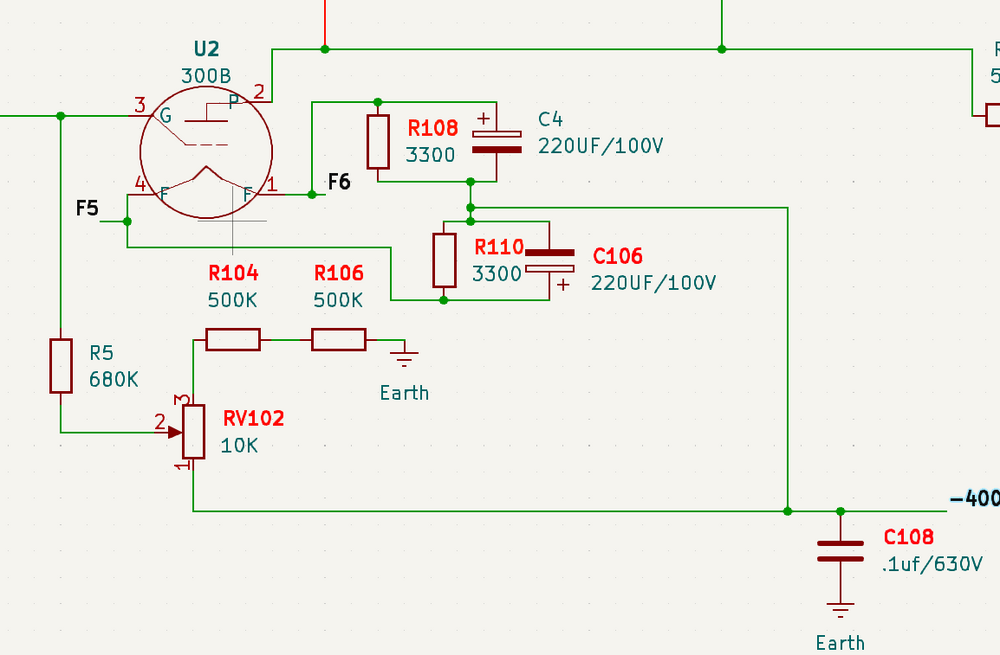

The grid’s pull-up resistor is R5 (680 K), and the pull-down side is two 500 K resistors. The 10 K trimmer (pot) has a very small effect, just about 1–2 V of offset adjustment range. With the current 7500 Ω cathode resistors, Vgk is roughly –76 V. To reach the WE datasheet’s recommended value, the cathode resistance would need to increase further, but that would push the offset even farther out of range. So the grid trimmer really needs to have more authority. The 10 K value is clearly too small here; something like 50 K or even 100 K would likely be a better choice. I’ve noticed that at this: 75 V operating point, there’s slight low-frequency distortion at high volume. I’m not sure if that’s because Vgk is too negative (too “deep”) or not negative enough. Yep, it’s a real hassle. At the very least, having to remove and reinstall the PCB every time is incredibly annoying.

-

Today the 7.5 kΩ resistors I ordered arrived. To swap all eight cathode resistors I pretty much had to remove every screw on the chassis. Long story short, the offset is much improved, going from –100 V to about +10 V. Big thanks to @JoaMat for the help! For me, this voltage is acceptable, but if someone wants to get even closer to 0 V offset, I think 7.0 kΩ might be the sweet spot. Also worth mentioning: the G-grid adjustable pot on the board offers around 2–4 V of Vgk trimming range. My 300Bs are running at ±400 V, since I feel 450 V is pushing things a bit too much. I think the main reason(Correct me if I'm wrong) for the original –100 V offset was that the cathode resistance was too low, allowing too much current. This made the anode current too high, and because the EL34 CCS isn’t perfect, it compensates by lowering its voltage output. With the original 3300 Ω resistors, I saw the B+ drop from 400 V to 370 V under load. One more note: after increasing the cathode resistor, Vgk sits around –80 V. For safety, I’d recommend replacing the original 220 uF/100V cathode bypass caps with 160V rated ones. More pictures will be posted later.

-

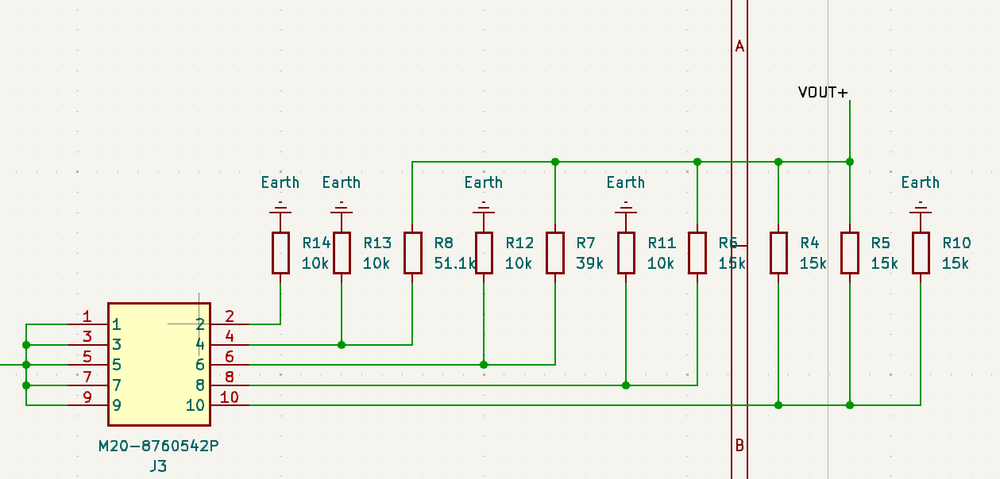

Last night I did the first power-up. I used some very inexpensive 300Bs just in case anything went wrong and to avoid risking the expensive tubes. Balance was actually very normal. About 5 V on one channel and 3 V on the other. But the offset was around –100 V on both channels. I’m guessing this is the “–100 V output” issue you were referring to? Let me know if that matches what you’ve seen. I haven’t had time to swap the cathode resistors yet. Measured Vgk is about –42 V, which is clearly not deep enough. I’ve ordered some 7.5 kΩ resistors, which after calculation should bring Vgk closer to –90 V. Also, for anyone interested, here are the LMQ66430 output voltage setting resistor positions I used on my board: M20-8760542 is a header pin jumper. 1–2: reserved positions 3–4: 6.3 V 5–6: 5 V 7–8: 2.5 V 9–10: 1.5 V Hope this helps anyone planning similar setups.

-

I’m planning to use ±400 V for the supply with an anode current around 23 mA. I noticed that on Kevin’s PCB layout for the 300B, the cathode resistors are shown as two 3300 Ω parts. Do you think I should replace those with 3600 Ω instead? Also, for filament voltage switching, I’m using the pin header setup shown below(MPN: 0010897120). Each row corresponds to 2.5V, 5V, 6.3V, and 12.6V, and I also left one extra row reserved in case I need it in the future.

-

I used an inductor from Coilcraft, MPN: XGL6020-222MEC. The manufacturer claims it has the lowest DCR in the industry for its class, and it’s also very compact at around 6.71 x 6.71 mm. For the output voltage selection, I set it up with a few jumpers to switch between different resistor values for 2.5V, 5V, and 6.3V outputs. If you need help calculating those resistor values, just let me know. Also, I’m curious. When you switch from 300B to 2A3, did you modify any surrounding circuit parameters, or can you drop them in directly (aside from changing the filament voltage)?

-

I took a look at the datasheets, and their Vgs vs. Id transfer curves actually seem fairly similar in the linear region, so I think they should be directly swappable. But it's probably best to measure the Vgs your circuit runs the C2M at, and then check if that voltage still lands in the linear/controllable region for the C3M. That's my understanding for using them in something like the GRHV, though I haven't factored in the overall feedback loop behavior here. So not sure if I'm missing anything on that front. I have ordered a pair of C3M and have a Carbon on hand, A straight swapped can be easy. Will report it later.

-

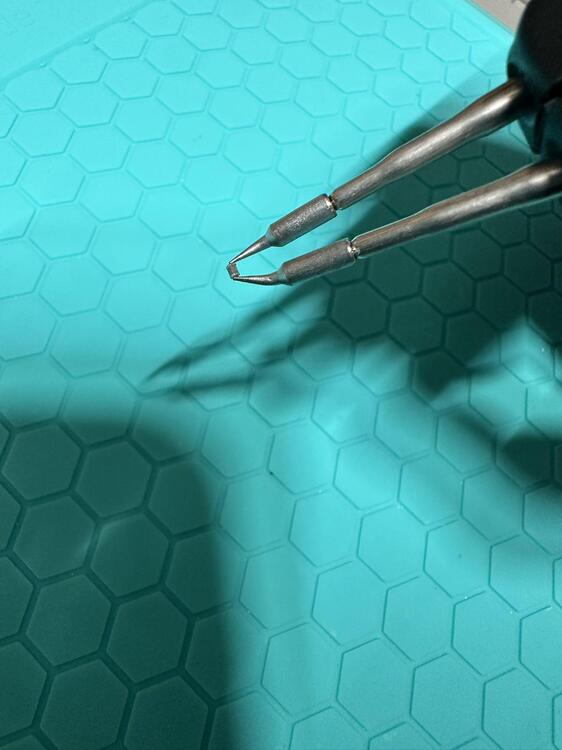

Great to know that. You could further reduce the PCB size by using a compact bridge rectifier like the CSPB40K-HF. It has a much smaller footprint compared to standard rectifier packages and still handles decent current. Like the way how you fix and test the 2A3 tube. Recently, I purchased these soldering tweezers from JBC to perform SMD work. Nice and decent.

-

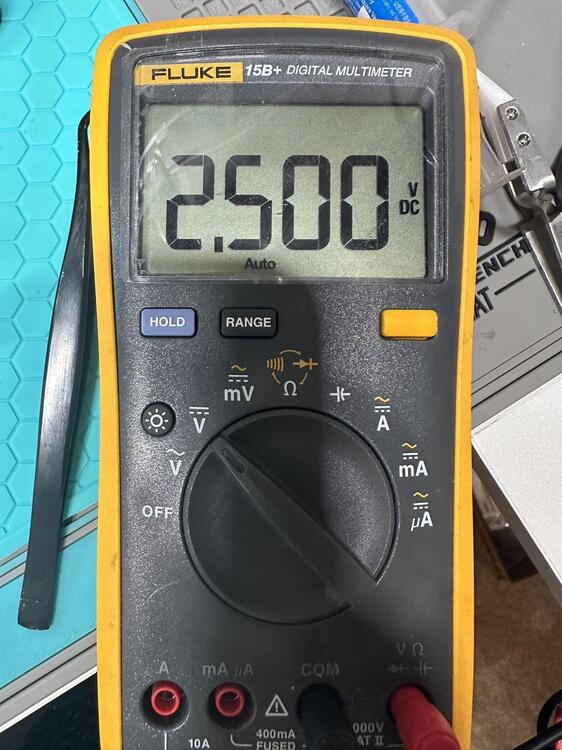

Good news: It works! Measured output is 4.9V for the 5V setting, 6.1V for 6.3V, and spot-on 2.5V for the 2.5V setting. I haven’t tested the soft-start function yet — if anyone has good suggestions on how to choose a suitable load resistor for testing, I’m all ears. Bad news: I spent two days figuring out how to hand-solder with a heat pad and heat gun the QFN package. Even when using a stencil, too much paste tends to remain on the pads, which makes them very prone to shorting. As a result, I ended up ruining two boards and some components. At this point, I really don’t feel like assembling the remaining three boards myself. I think it’s best to leave the rest to a proper assembly house. Updates: Soft start works. About 3.5ms rising edge time for 6.3V.

-

Find it. I will share the info here anyway if you are curious. The switching freq range is between 900 to 2400(kHz). Lower than the LMQ, but shouldn't have any problems. https://www.ti.com/product/TPS62913

-

It's a great idea. I’ll likely move forward with the current plan for now since I’ve already ordered the PCB prototypes, but I definitely want to explore how that auto-detect function works. My guess is that it detects the difference in cold filament resistance between 2A3 and 300B tubes, but I’m not exactly sure how it’s implemented in detail. I’ll need to dig into that more. Also, from the image you shared, you reminded me that I should probably add a few small ceramic caps for filtering (like C9, C8, C7 on the right side of U1). Thanks for the heads-up.😅 The test PCBs should arrive this weekend. If I’m able to populate and test them successfully, I’ll report back with results. BTW, do you know what kind of DC-DC chip on the picture? Too blurry for me to read.

-

Thanks Kevin. I went back and double-checked the schematic. You're right, each 300B does have its own separate filament supply. In this way, would it be possible for me to use four individual 2A/3A DC-DC modules to power them separately? BTW, how’s the D&G project going? I remember it requires something like 10V at 8A or even 10A for the filament supply. That’s already more current than a typical household socket can handle for just the tubes! I’d love to hear more about the D&G if you’re open to sharing. I got the chassis at the end of 2024, the link was expired for a while but i do believe you can find it somewhere else. For GG building guide, you can browse the GG thread, it has all the info and issues you may like to know.

-

You should easily find it on eBay or somewhere else. Regarding the file, it is not mandatory for GG. You should complete the build by populating the GG boards only. Otherwise, you need to figure out the drilling distance to perfectly make the center board fit well, which is unnecessary.

-

This post is a bit long, but if you're interested in alternative filament supply ideas for DHTs, feel free to read on. I know @kevin gilmorehas already mentioned and implemented a solid filament supply solution for 300B tubes using five modular switch-mode power supplies from Traco. One 12V unit is used for controlling soft start, and the others supply 5V for the 300B filaments. It’s a good and proven design. However, I believe it may take up more space than I can afford in my chassis, so I’ve been working on an alternative. Summary of My Design Concept: 1. Inspired by @JoaMat approach using rectification + DC-DC regulation, aiming for a similar or smaller footprint. 2. Native soft-start behavior with no need for external resistors to set ramp-up current or output voltage. 3.Up to 5V @ 3A output per module. 4. Molded inductors for reduced EMI 5. Adjustable switching frequency (to avoid audio band). 6. Dual-random spectrum modulation for further EMI suppression. 7. No heatsink required. I’m currently working on the PCB layout based on my schematic (slow progress – I’m not a professional). Any suggestions, corrections, or feedback would be greatly appreciated! 1.Design Rationale (skip if you’re only interested in the result): There are many DC-DC converter chips available, but my criteria were: Very small footprint Adjustable switching frequency (to avoid 20Hz–20kHz band) Integrated soft-start, over-voltage, and over-current protection (to safeguard DHT filaments) Output current ≥2A @ 5V Low noise and ripple Adjustable output voltage (to support both 2.5V for 2A3 and 5V for 300B) After some research, I settled on the TI LMQ664x0 series, which offers 1A/2A/3A variants. To leave some headroom, I chose the LMQ66430, rated for up to 3A output and 36V input. Datasheet:https://www.ti.com/lit/ds/symlink/lmq66430.pdf This chip is extremely compact – only 2.6mm x 2.6mm – though I’m still unsure if I can hand-solder something that small.☹️ 2. Circuit Topology (text version for now): Although I’ve drawn a test schematic, the files are on another computer. I’ll post them later if needed. In general, the topology is quite typical: Use a transformer with a secondary in the 9–16V AC range, Rectify the output, Feed it to the LMQ66430 module. Key connection notes (based on the datasheet): PIN 1 and PIN 3: Rectified DC input PIN 6: GND PIN 7: Output through an inductor (preferably molded) PIN 8: NC PIN 10: 1μF to GND PIN 11: Feedback resistor network for setting Vout (see page 29) PIN 13: Set switching frequency (tie to GND for 2.2MHz; see page 14) PIN 14: NC PIN 15: GND For layout reference, check Page 39. Also, combinations and example circuits are shown in Page 9.2 Disclaimer: I haven’t verified every detail yet. In this way, there may be changes before I finalize the layout and perform live testing. I have some concerns if two modules can work in parallel. In Megatron XL, the two 300Bs per channel share the same filament supply. If I use two separate LMQ66430s in parallel, I’m unsure whether uneven current draw might become a problem, since these chips don’t have a master/slave current-sharing mechanism. I have another separate question, please bear with me for bringing this up here: If I substitute 300B with EML 20B-V4, I understand that I no longer need the pair of 3300Ω balance resistors and should instead use a cathode resistor connected to the center tap (CT) of the filament. But I’m unsure about how to treat the G-stage resistor R4 (680kΩ). Should it connect from the grid to the cathode, or from the grid to -450V? My guess is that the G-stage connects to -450V through the 680k, and the cathode bias is set independently via the CT, not the filament ends. I admit I’m not very confident when working with DHTs – I often get confused by how CT-based cathode bias works when combined with DC filament supplies. Any insight would be really appreciated!😊