-

Posts

9,101 -

Joined

-

Last visited

-

Days Won

175

Content Type

Profiles

Forums

Events

Everything posted by VPI

-

-

I am going to turn it off and turn it back on again. It was a full 7.5 inches too Y but the X seemed close. Had it return it it's X,Y Zero and it went right where it was supposed to.

-

Bottom left, just like it was on the lake and everything else as I think it is set once for the whole project.

-

Nope. Never started, I stopped it when I saw it go way past the part of the sign it was supposed to be doing and was about to put my street number right in the top part of the lake. Half the sign away from where it was supposed to start.

-

If I end up getting the sign built without a disaster, any stand will be acceptable. Finished the biggest pocket and moved to the second largest, which is on the opposite side of the sign from the other and the CNC just screamed back to the middle of the big one and was going to try to cut it there. Everything runs right in simulation so I have no idea what I have screwed up.

-

Yeah, my concern was the 4x4s shrinking/twisting while glued to a non-stretching hardwood in the middle. I think an inset domino job will be the best way to go…if I can remember how to do one of those. Or maybe a welded steel holder for it.

-

Yeah, I was thinking dominos but worried the treated 4x4s would shrink down and cause issues with solid connections to hardwood.

-

Have some woodworking advice needs. I am building an address sign of sorts for the driveway and I am trying to come up with a way to hang the sign between two 4x4 cedar posts, so that doesn’t swing in the wind and has minimal visible hardware. Any ideas?

-

I did manage to finish the first “project” on the magic side table. Did the key tray with 1/4” downcut windmill followed by the bowl bit to round the bottom. The large one was done with the 3/4” bowl bit and came out much better.

-

No issues. 1/2” and noise but it fought through until I could press one of the 70 emergency stop buttons. The funniest thing is I spent 10 minutes trying to figure out why Walnit was falling to the bottom shelf of the CNC cart before realizing my dust collector bag had split and was blowing chips onto the adjacent stand.

-

Would you like to know the sound of a 3/4 bowl bit digging in without ramp .5 inch into Walnut? I know.

-

I have discovered that CNCering is a whole lot of standing around hoping nothing blows up.

-

Managed one test before blowing the fuse, which I cannot get locally, with the giant 2 inch spoil board flattening disc. Will probably just plug the spindle into its own circuit and love with plugging it in each time instead of running off the controller power supply. Finding the spoil board design to be lacking as I have too few t tracks. Might just use the base layer and screw/glue wood to the MDF, once the midget fuses finally arrive.

-

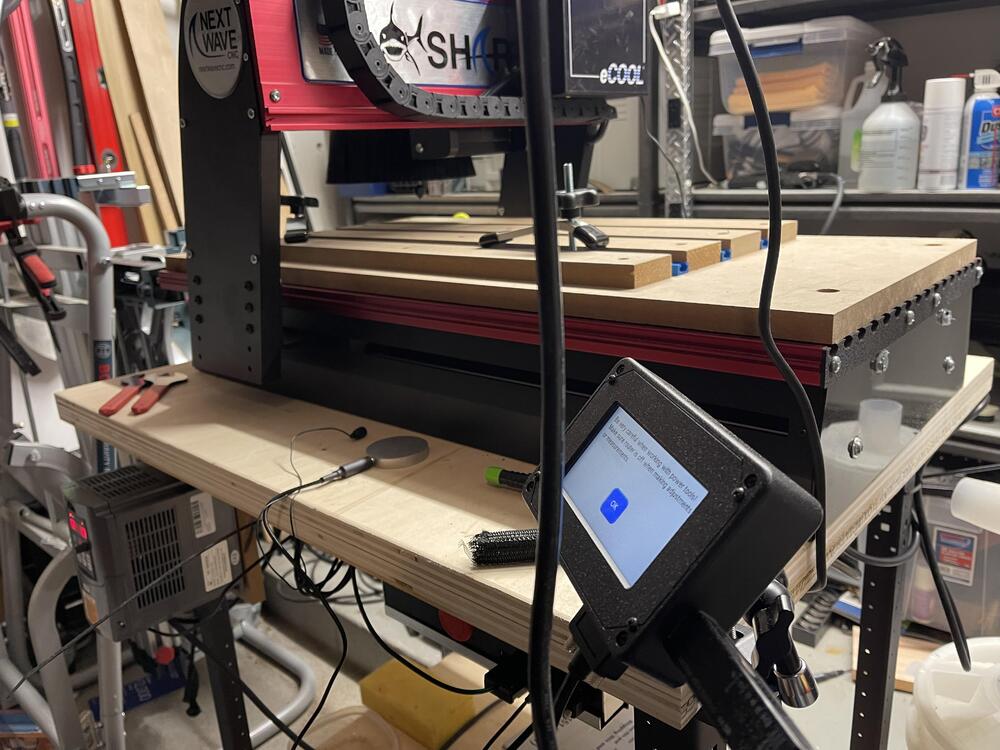

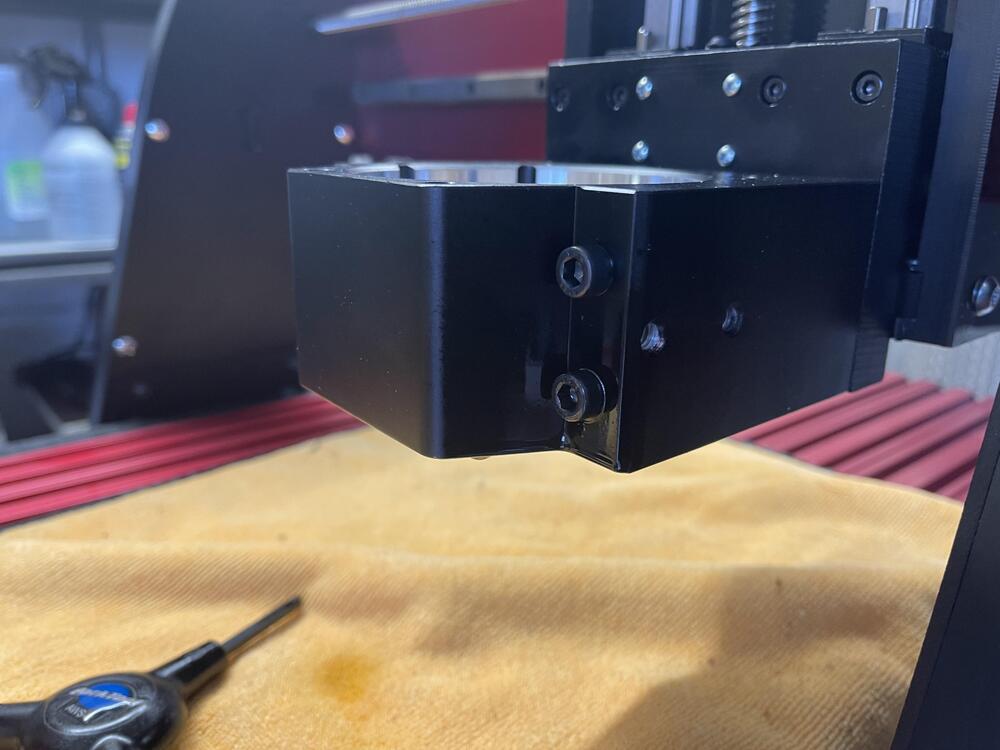

Finally got the whole magic side table together and did a test cut for an upcoming personalized drawer front project. I guess with the new 3HP spindle it needs to be set almost all the way at the top of the clamp to allow the dust boot to actually enclose the bit and suck better. IMG_1923.MOV

-

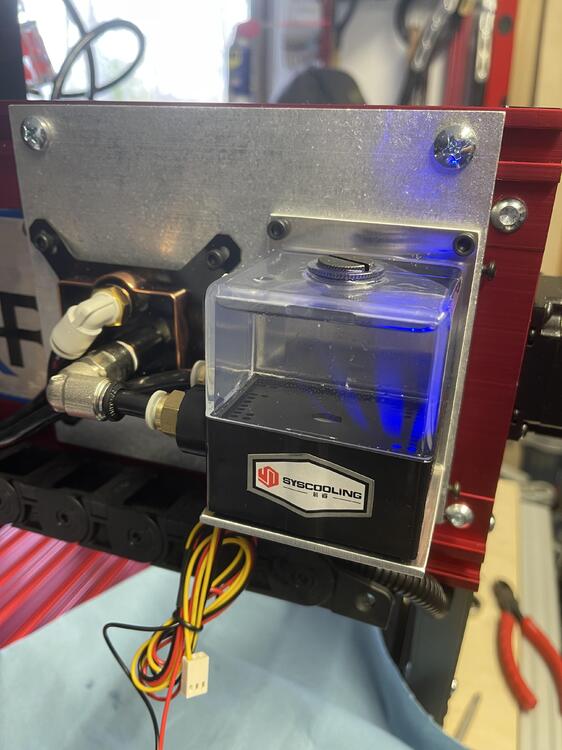

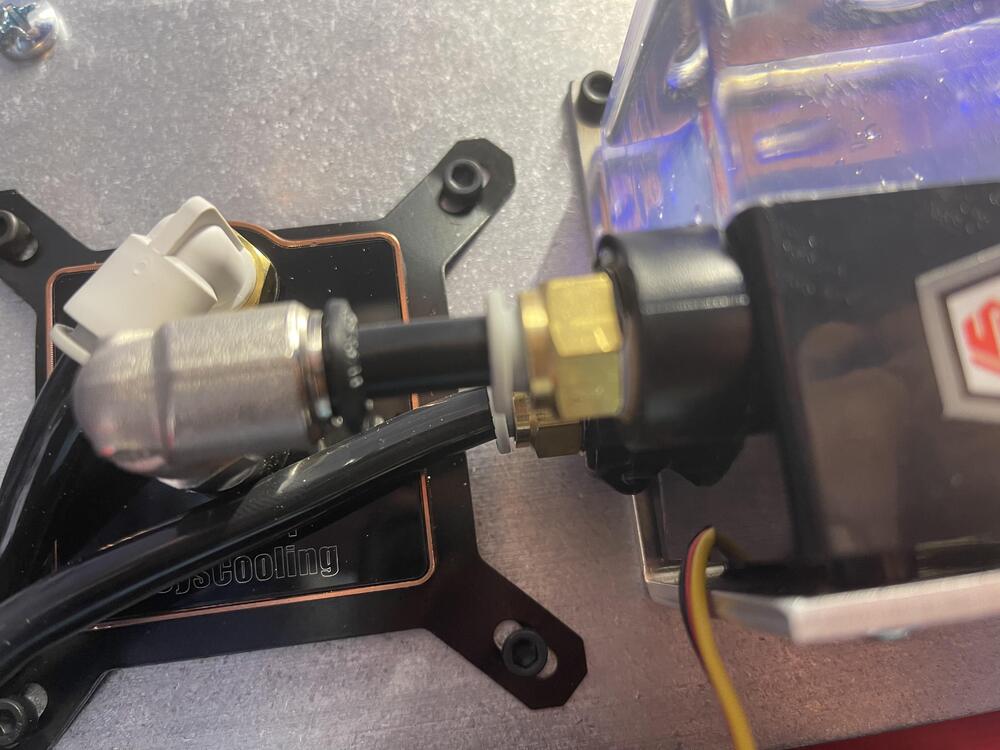

Got the replacement cooling unit. Missing one piece of tubing and the case has an issue some may spot. Quality QC here for sure.

-

Shitty chilled water system is heading back to Ohio for replacement. Might just build my own without Ali Baba parts everywhere.

-

Full of Propylene Glycol at the moment so I have going to have to pump the whole thing out to see if the hoses that came attached were actually properly done.

-

Cheap PoS Chinese cooling system is leaking at the hose leading back into the reservoir from the spindle and not spinning of the flow indicator at the spindle.

-

Making through plumbing and wiring now. I find it hilarious that Next Wave tells you in several places that you should never support the weight of the dust collection hose on the gantry and it has to be hung from the ceiling, while saying nothing about adding 55lbs of junk and liquid to the gantry for the spindle.

-

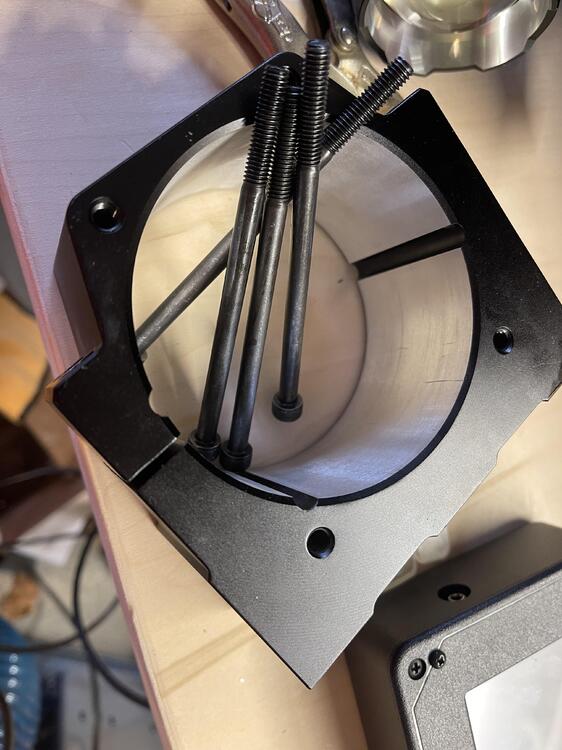

Holy fuck, what a pain in the balls. Finally got all four bolts out since this piece has to come off for the new spindle mount. The last bolt would not move with heat, mallet, etc. and the impact was just going to round it out. Ended up having to use a rubber mallet on the router mount to twist it around and finally broke the last bolt loose.

-

I was leaning towards the spindle; but as I have no idea at this point if I will ever figure out how to work this thing, I went with a spare router for the moment. The neighbors are both deaf, but Kasia works 12 hours a day, everyday on phone calls so it might be problematic.

-

The water cooled spindle will help, but it is had to get at the moment as they have been upgraded and everyone is buying them up. I could skip the new 3HP and get the older 2 HP, which is probably more than enough for me. Still trying to figure out dust. I have that dust extractor right next to it that I thought might work if it suspend it from the ceiling and step down to the dust shroud 2 1/4 size.

-

The issue is, the bolts are four inches long and only the last 3/4” of an inch is threaded. I would have had to heat up the housing. After breaking 3 Allen wrenches I got a long ass one and a rubber mallet and went to town. Got it in but what a shitty fucking design.

-

Made it as far as I can go as three of the 4 steel screws are completely seized inside of the aluminum spindle holder. Tried everything I have and nothing as much as budges any of them.

-

Bought the CNC directly from the manufacturer, assuming they would just send along the freebies with the package so they do not have to go through the hassle of another shipment. Nope, I have to register the CNC with them first, and I cannot register it until it is built because all serial numbers are hidden within the controller for some reason.