-

Posts

9,101 -

Joined

-

Last visited

-

Days Won

175

Content Type

Profiles

Forums

Events

Everything posted by VPI

-

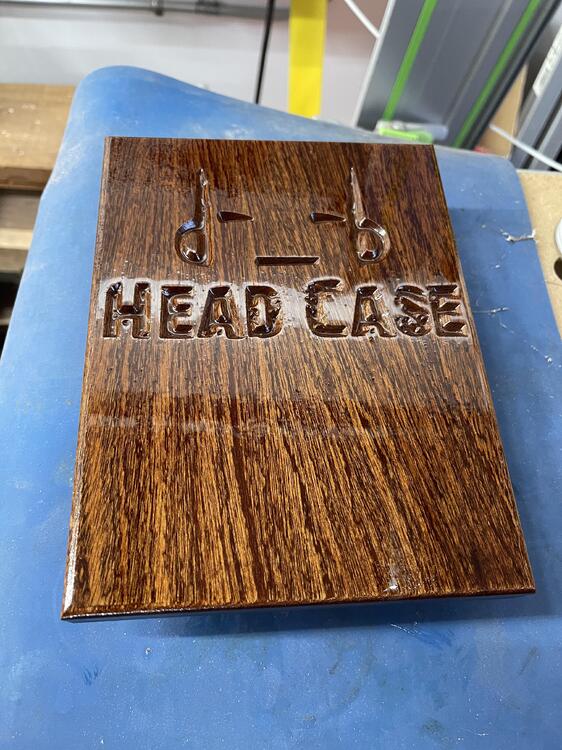

Finished, with minutes to spare a set of these. Kasia asked, of course, why there are two openers on each and the answer, of course, was because this is fucking Head Case. and not that I gave fuck all thought to where screws were coming through the front when laying out the keyholes in the back

-

Working on party favors for a little headphone/craft beer nerd get together this weekend. Took forever to cut the 3D rendering of the logo but all done and used the new keyhole bit to cut keyholes for mounting on the back. Putting sealer on tonight so I can finish with boat varnish tomorrow. Then just add the bottle openers and done.

-

I pay other people with their own chain saws to deal with all that shit.

-

The middle one shines 1800 meters, the big one does a flood of 12k Lumens and the little one is too cute not to buy. Obviously.

-

-

-

Trying to design a tray for CNC bits. Can fit many more if I stand them up, but then I need a deeper drawer.

-

Finished the new drill station, which meant I get to trash one of my earliest builds, back when I just got the Track Saw and had nothing else. Just need to add some kind of finish, cut out a power cable hole or two and put a cleat on it.

-

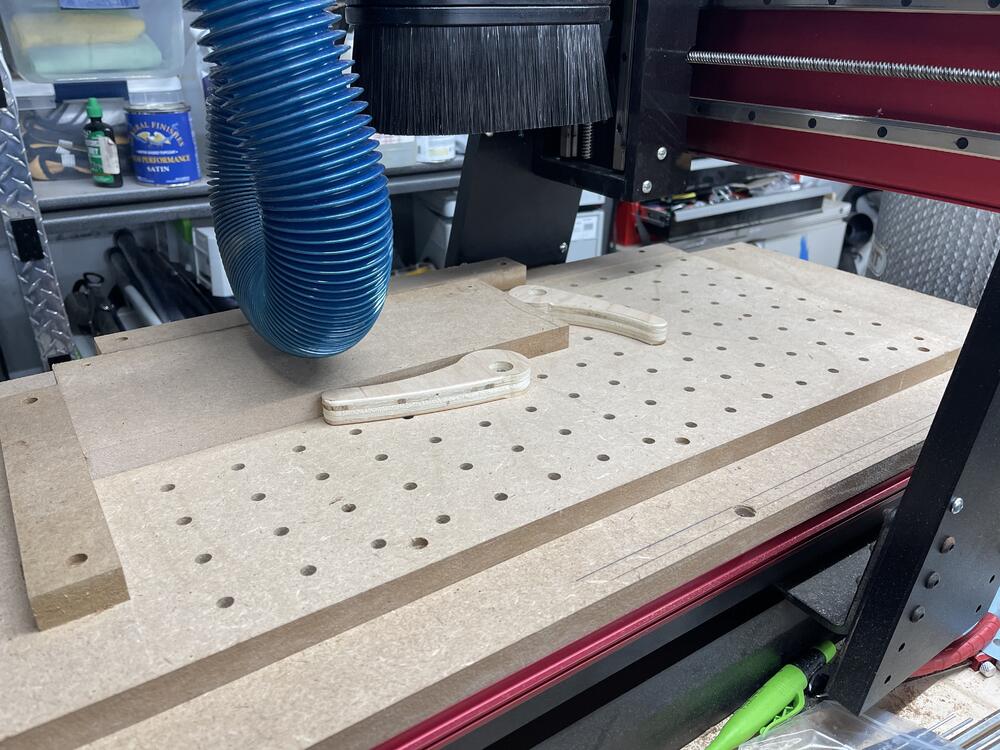

Finished the spoilboard. Not exactly what I wanted, but the only way I could maximize real estate on the small CNC.

-

Managed to make the clamps for the CNC, but have not figured out how to make the spoilboard. Having a 16x36 table with only a 13x25 cutting area makes shrinking the Tools Today spoilboard to work and actually line up kind of difficult.

-

Is Fred one of those YouTube woodworkers I keep hearing about. The light switch seems so much easier than turning on my bandsaw. Would be nice to be able to cut wheels to fit any bandsaw blade I find while dumpster diving around Chicago.

-

New VFD should be here today. Hopefully this one will last longer than three months. In other news, found this sweet bandsaw on marketplace and I am thinking about upgrading.

-

CNC decided to quit communicating with the VFD for the spindle so dead in the water while I was hoping to do the new ToolsToday spoilboard today.

-

My podcast with the Chief of Police in Austin on police reform is out on all your favorite podcast providers. He wouldn’t stop playing with his key ring the whole show, but it is an interesting look at how they are changing police training to train police that fit better in today’s world. https://podcasts.apple.com/us/podcast/security-concepts/id1532932465?i=1000569008541

-

-

-

-

Our deck furniture has been over a year wait, but is supposedly going to be here in July.

-

Found out on the plane on the way back from the COVID mixer in Boston that my Aunt Sharon Keltner died of a heart attack Thursday night. She was probably the nicest person I have ever spent time with in my life and did nothing but give as a life long RN and in retirement feeding the majority of her small town that is primarily comprised of very old farmers with little money. Family was planning a joint celebration of her 70th birthday and 50th wedding anniversary for August. Time for me start living a healthier lifestyle.

-

-

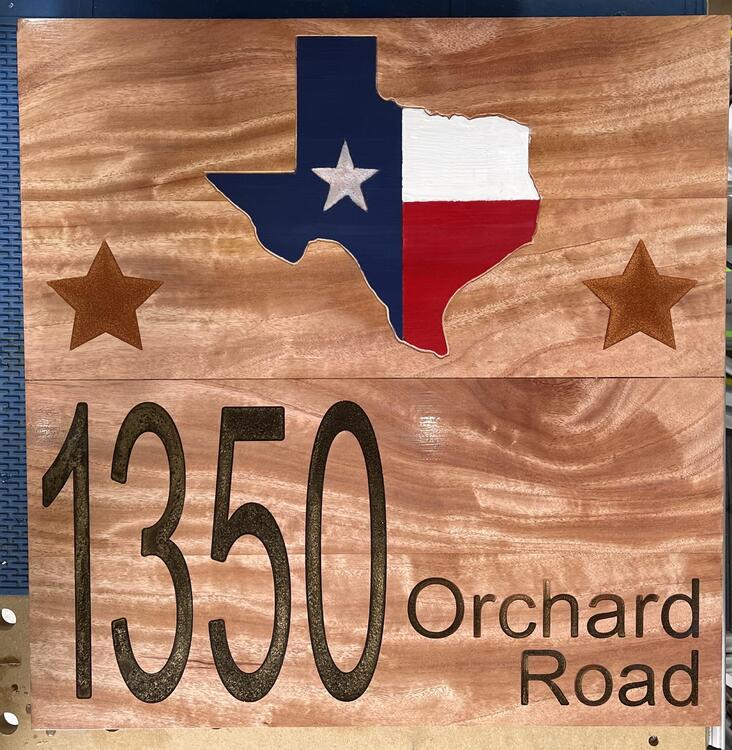

This one was a strange cut as it was the for the plug of an inlay. In VCarve Desktop I cannot see any way to change the depth in the VCarve function by adding passes so I just went with it. Did the top of the clear out and then went to the middle and was not set to ramp so it plunged and started doing its loops and snapped off. It was an Amana Spectra Coated 1/4” down cut which had a nice clean shear right at the collet mark on the bit. Collet should have been pretty damn tight as I tend to be paranoid about random flying 19000 rpm projectiles. In better news I finished the carve of the next yard sign with no drama. This one has such interesting grain, I am not sure if a basic brown text resin will even stand out. Going to paint the Texas, as I was not smart enough to come up with a way to carve it that I could fill with three different resins without having a big purple Texas.

-

Broke my first CNC bit. Clearance pass for a v carve on an inlay plug. Ended up being about .15 inches on the first pass, which evidently was too much for the 1/4” downcut bit.

-

I love my Milwaukee M18 Fuel gear. It is pretty much my whole arsenal from chain saw to leaf blower here. Spade bits are fucking awful bits for pretty much anything and if it is no longer sharp after hundreds of holes, I would ditch for a 1” auger bit. That is what I used to drill holes so I could fill a stump with kerosene before torching it. No issues as all with the Milwaukee drills. There is no reason any drill cannot drill into cedar, unless the bit has been worn down to a spinning blunt object.

-

Good point on the Sipo dominos. Had to order those online as no one local has them. More delays as the cold front we are having here is making everything go really slowly. Garage is hovering around 55 degrees and no heat in the forecast until next weekend at this point. Made pouring epoxy resin a pain in the ass.

-

Wrapping up the yard sign with Total Boat Halcyon varnish all day today. The only thing that will not be completely sealed is the sides where they will domino/glue into the 4x4s. Should I varnish the outside edges of the side to keep this waterproof or will a tight glue up with Tb3 be sufficient?