-

Posts

13,716 -

Joined

-

Last visited

-

Days Won

39

Content Type

Profiles

Forums

Events

Everything posted by luvdunhill

-

If you happen to have a list of current requirements for all headphones minus a K-1000 I can try and answer that one for you ... otherwise, remember, there is no such thing as overkill in this hobby, especially in a Kevin Gilmore design

-

good question. Better find an appropriate floor wart for interested builders quick!

-

I'd say they compare favorably to commercial amps in the $5K range.

-

pshaw.. no one is actually going to listen to these, they are just for show

-

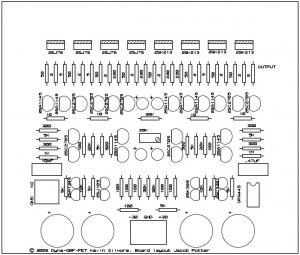

everything is through-hole

-

looks like this can scale up via adjustable bias and the psu... in this case, you can never can have too much aluminum

-

All this is totally up for discussion. My preference would be heat sinks that are totally external to the case. The heat sinks I got from Conrad are absolutely beautiful and the rabbited edge and pre-tapped holes make things very easy to assemble. There is the possibility that more of these would be made available, in which case this would be my recommendation. We could also interface directly with Conrad or R-Theta, both of which I've used in the past for things. Total cost to my door (as part of a large GB) was ~$100 a pair for the largest profile from Conrad. I'll post pics (some are in the n_maher beta24 thread) I suppose we need to run some numbers on the output device heat dissipation.

-

I'll post silk pics tonite. I'd recommend 1 sigma22 per pair of boards. I was thinking "by build" to mean just stuffing the PCBs, as well as some other task, like matching devices and/or helping with procurement of various aspects of the build. We need to consider casing as well, but I'd recommend a one size fits all casing option. I already have some ideas for this. Mounting holes would indeed be the same as Dynahi boards, but I'm only entertaining the off board heat sink layout (see post #1).

-

If it's from Thom, it's possibly the MintLP as he really pimps those. There was a point where he was handing them out for free, so he has the ability to produce them definitely.

-

Al, as someone who obsesses about cartridge alignment, I'd recommend the relatively cheap investment of an arc protractor. While the Wally Tractor might be the bees-knees, I'd go with either the MintLP or even the cheaper one made by KWILLIS on Audio Asylum. These options run the gamut in terms of price, but the KWILLIS is around $50 I believe. The nice thing is they are optimized for your arm / cartridge combination. The improvement of a properly aligned cartridge is quite simply work the added effort. enjoy!

-

ah the 6-channel "nomenclature". I think you really want 4. But, yeah that's the idea. It would look like: luvdunhill - 8 - 4 Asr - 0 - 4

-

I suppose you could recess the switch in the front as well. I'll let you decide Here's hoping the wood shows up today!

-

If you have to ask, this probably isn't the project for you I have no desire to calculate the rough cost honestly. Obviously things will be done in mass in order to keep the cost down, but the idea is to get things done in parallel and when possible just build them all identical with maybe one or two options. That's my vision at least.

-

that's the idea here. Again, no real time frame and I'll have to work out some sort of compensation for the "builders" that's agreeable. Just add your name to the list.

-

I think so to. Plus it's going to be awesome to get some of these in circulation at meets and what not

-

ok, so next step is to estimate the number of channels that will be built so I can get enough parts for everyone. Also, if you are a DIYer, indicate how many channels you'd be willing to build. I think we can accommodate everyone in this thread, including the non-DIYers. Just quote the following list and add your info: name - # channels willing/able to build - # channels wanted to have and hold luvdunhill - 8 - 4

-

according to the docs max panel is 11mm. or 0.4331" or 7/16" or 6.83554293

-

I bought the perforated aluminum from onlinemetals. I'm very happy with it! yeah, about 3/16". 4mm to be exact. The recess is 12" x 4.875" wide. I dropped the wood in the mail this morning and pickup was at noon, so I'm guessing you'll see it tomorrow. Also, remember the back of the wood will be right up against some hot heat sinks .. would it be best so space it out a tiny bit so it's not touching?

-

I'm thinking about finding a bunch of 2SK1530/2SJ201 pairs. If you have a good source, I'd love to hear about it

-

Official Thread: Joe Grado will not be at "Yes, We CANS 2009"

luvdunhill replied to morphsci's topic in Meets

Told you this DannyB guy was a spammer.... nobody listened to me... -

Looks like we need a "How are you feeling today" thread

-

yeah, we had a similar experience with our youngest recently. Came down the croup and we tried to hold off as long as possible without giving steroids to the little one... but off and on three nights in the bathroom with the shower steam kinda gets old ... not exactly С лёгким паром!

-

yes. One for case the wall warts and the other case will have an Altoids tin can strapped to the bottom with cable ties with Black Gates on the outputs.

-

until you realize she's allergic that can be exciting.