-

Posts

1,539 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Forums

Events

Everything posted by JoaMat

-

I bought some DC bricks from LCSC Electronics. Seems to be an all-right supplier. https://www.lcsc.com/product-detail/C2999063.html

-

Lovely, finally some use for circlotron psu. Most things settled - only finance issue… no prediction.

-

Thanks. I avoid ebay. Goods tend to be stuck or disappear in Swedish customs. Suggestions about +/-750V?

-

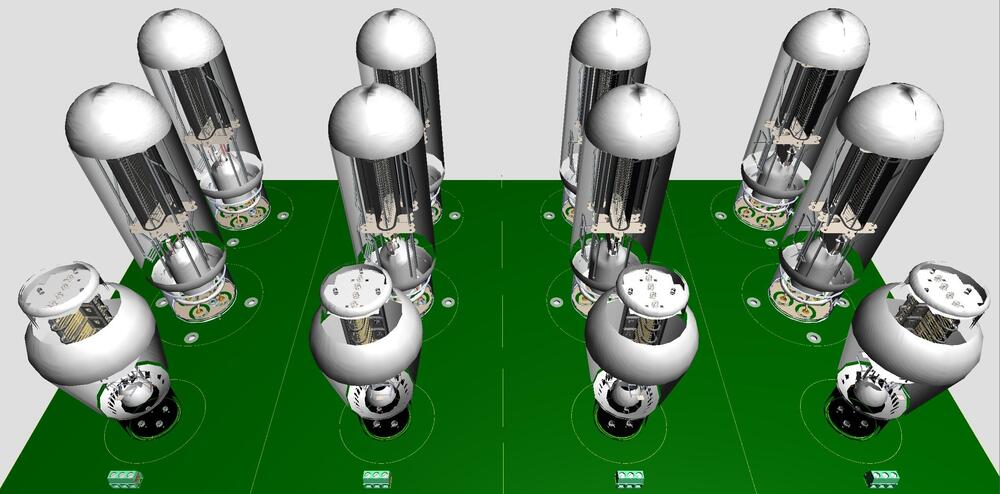

Yep, I’ve noticed output and filament boards match up to each other. Here is how it looks like on my screen, all output tubes side by side. Size 24 in x 12 in – huge. Question regarding jumbo socket – what socket do you have in mind? This from a French company might fit.?

-

Have made schematic out of Kevin’s published gerbers of David and Goliath filament. From schematics a PCB layout following the original gerbers is made and the above 3D model is the result. I’m addicted to make my own twist of others work. So, now can the process of shrinking Kevin's board start. Just to be clear, David and Goliath project is insane. I like that.

-

-

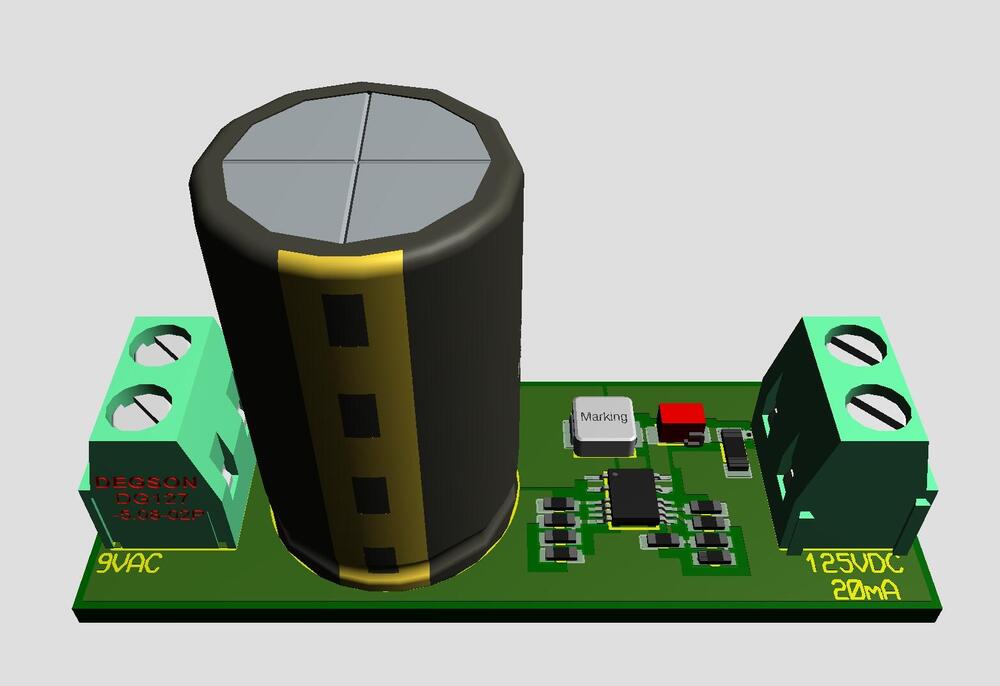

I’m looking for a way to produce 125 VDC low current. One idea is to use a switching voltage regulator, LT8365 maybe … board size 2.0in x .73in (51mm x 18mm)

-

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

Thank you, Shawn. Good to know how Megatron XL behaves. -

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

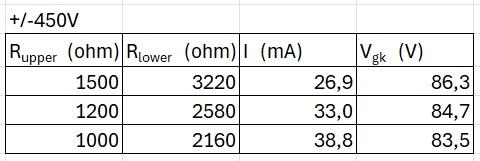

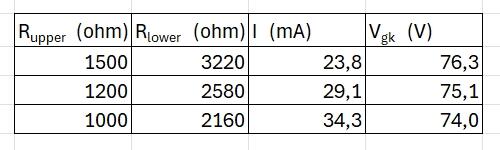

Please do. Silk screen says +/-450V, I think. I got this table based on LTspice simulation for supply voltage +/-450V. Rupper is upper tube cathode resistor, Rlower is lower tube cathode resistor, values give offset zero for given Rupper , the resistance is the total of paralleling resistors. -

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

I use LTspice to understand and to get a hint how things work. I got this table with help from LTspice. Supply voltage +/-400 V, Rupper is upper tube cathode resistor, Rlower is lower tube cathode resistor, values give offset zero for given Rupper , the resistance is the total of paralleling resistors. Looking forward your findings. -

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

Thanks for the pin tip. This beyond my understanding. But as I see it, with 400V/22mA the Vgk will be what it will be with offset zero. 12 W with EL34 shouldn’t be much of a problem. My EL61 will also handle that, I hope. -

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

Thanks for your comments, @simmconn. The heatsink gets warm and user is aware of it. I think he is running at 400V/22mA and so far, it seems to work. If it gets too hot than he can’t use this thing - that’s life. For pin dimension. The first version used Neutrik XLR3 pins. They were perfect, diameter slightly undersized. But to short to be soldered direct to main PCB. When looking for brass rod the best I found was 2.5 mm so, I decided to try that. 2.5 mm works with my Teflon tube sockets. The user is informed of that pins are soldered only on one side and if pins come loose, we have to find a better solution or perhaps abandon this thing. I use Addnorth HT-PLA Pro filament. Better heat performance than PLA but not as good as ABS. I’m confident the socket isn’t a problem. It might be a problem with the transistor tab cover. I haven’t thought about the cover until your post - thank you simmconn. Now the user is informed, and he promised to keep an eye on the cover. -

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

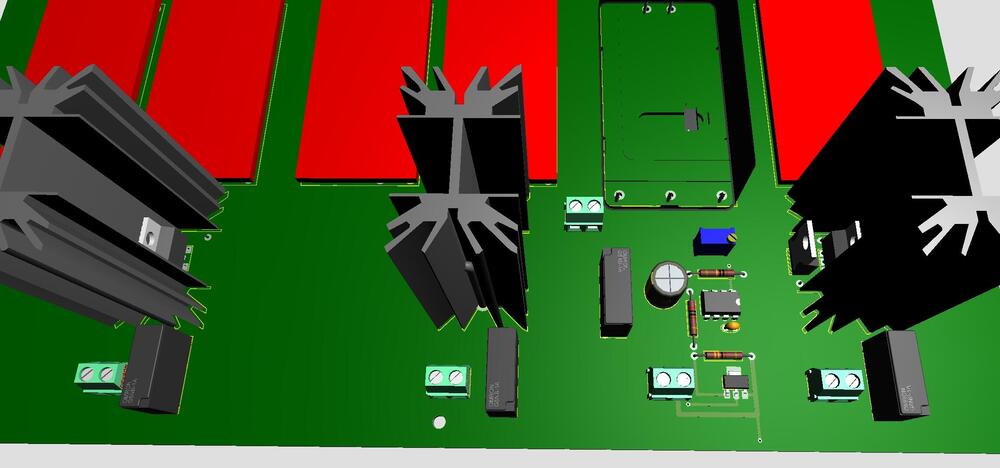

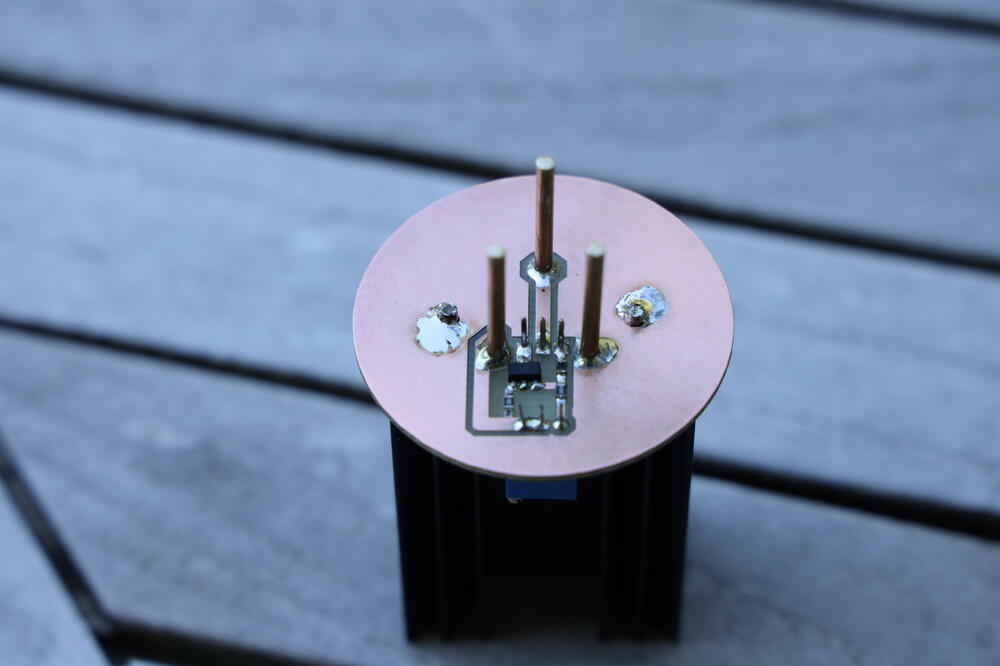

New solid state CCS for Megatron. Now with a third pin for ground. The pins are made from 2.5 mm brass rod, which is almost 0.10 mm thicker than tube pins. PCB is a CNC milled one side 1.5 mm copper clad. So, no copper on top side of PCB. Holes for the three pins are 1.0 mm deep and you have 0.5 mm epoxy laminates left. Transistor pins are protected with heat shrink tube and the exposed metal tab is protected with a 3D printed cover. The screw holding transistor to heat sink is electrical connected to it and to the ground pin. The white base with guide pin is made of three 3D printed parts. -

Fascinating chassis work. How about the scale of the altimeter? Small pointer one lap 1200 feet, two laps 2400 feet?

-

Please be careful with words. I do believe Mouser is a reliable company.

-

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

Thanks @Shawn. I have ”gathered” some info from three sets of 300B, one 2A3 and one 6A3. To me it seems that they behave quite similar and need about 7K – 7.5K cathode resistors. Your 50K trimmer (Grid Pot) will probably make it easier with the “fine tuning”. I guess you have put trimmers on the tube side of the board for easier access. -

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

After paralleling with a 3.3K resistor an increase of a few mA seems reasonable, but what happened to the offset? -

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

Glad you find a way to adjust the offset. With EL34 as CCS, +400V and offset close to zero, I believe 1.5K gives ~23mA and 1.0K gives ~34mA. -

Well, High Rollers. You can’t debate an angry person, waste of time.

-

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

How much offset can you trim away with the trimmers? I guess one need about 15K to get rid of +10V offset (with 2 x 500K resistors in the voltage divider). -

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

Yep, that's what I've seen. -

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

- -

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

I’m using a single cathode resistor. When you are using two 3300R resistors, as on your board, I guess that is equivalent to one 1650R. If you follow silk screen you will get -100V or so on output. You probably need to double resistor values. Maybe someone out there can tell more about this.