-

Posts

8,568 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Events

Everything posted by Pars

-

They have both the replacements in stock -200,000 of each or more. Sent from my iPhone using Tapatalk

-

I thought it was either the Xicon 271 or 273 series resistors that we’re used for the electrostatic amps? I could be wrong/behind the times... Sent from my iPhone using Tapatalk

-

Happy Birthday Mike! Sent from my iPhone using Tapatalk

-

and now for something completely different part 3

Pars replied to kevin gilmore's topic in Do It Yourself

Look at the schematic. The ones opposing are the pairs which should be matched if possible. It isn't critical however. Reading through the thread oftentimes finds the answers to questions as well... -

Happy Birthday Grahame! Sent from my iPhone using Tapatalk

-

Sorry for your loss Al. Sounds like a neat guy. RIP George! Sent from my iPhone using Tapatalk

-

Really nice Søren! Sent from my iPhone using Tapatalk

-

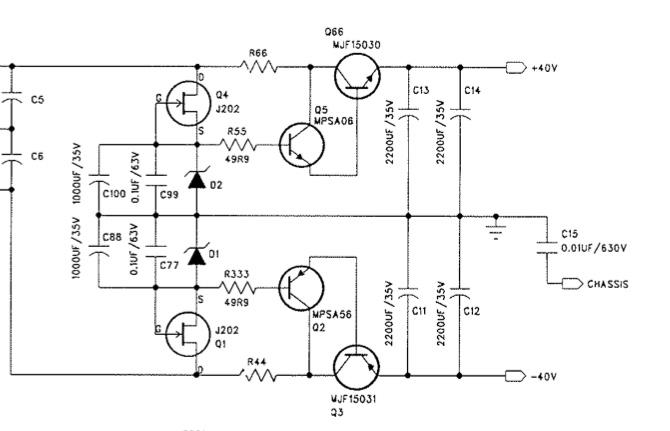

Yes, the ES lead spacing is larger, so I'd need to see if those might work or not. Otherwise, I guess I'll use the UVP. I measured the voltages for the issue where it showed 40V rails using 35V caps. It is ~29V (though might be higher at initial turn-on surge), so I think 35V caps will be fine there. The preamp is working fine, but having this occur made me think I might want to get proactive about it. Cost is under $70 to do all 73 or so caps, so other than the labor (and of course the opportunity to brick it), I'll go ahead and do this in the near future. I do think I will discontinue leaving this on all the time however.

-

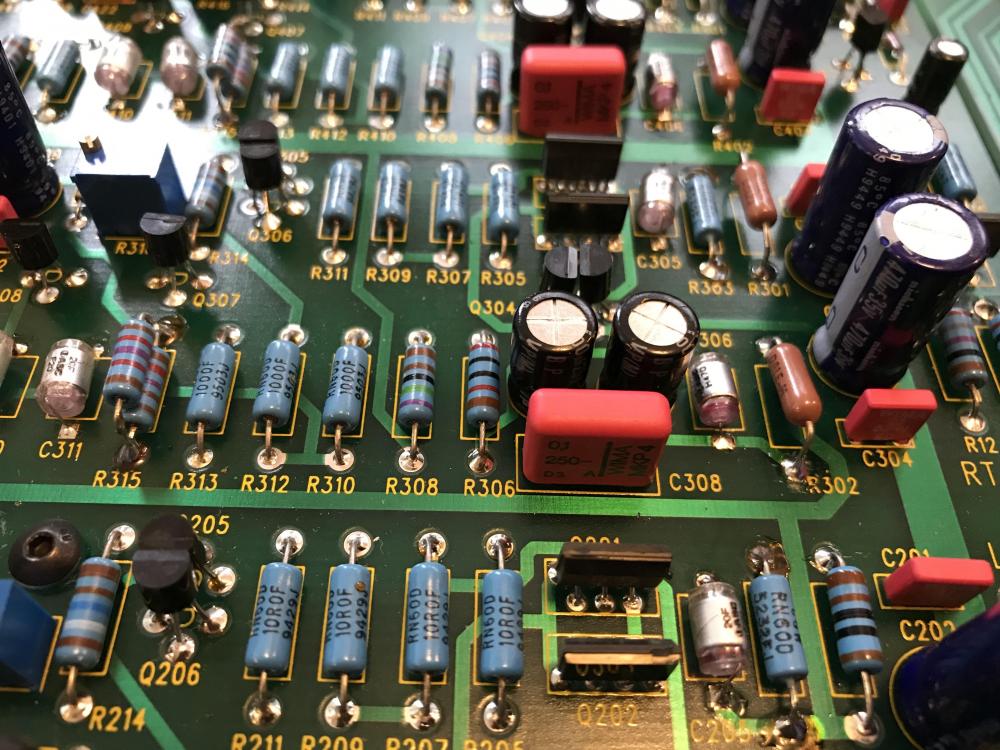

I just noticed that one of the cap types on the amp section is a Nichicon VP bipolar type. What would you guys use for bipolar application... It is 100uf/25V, 3.5mm lead spacing, so unfortunately this is too much for a film cap of some type.

-

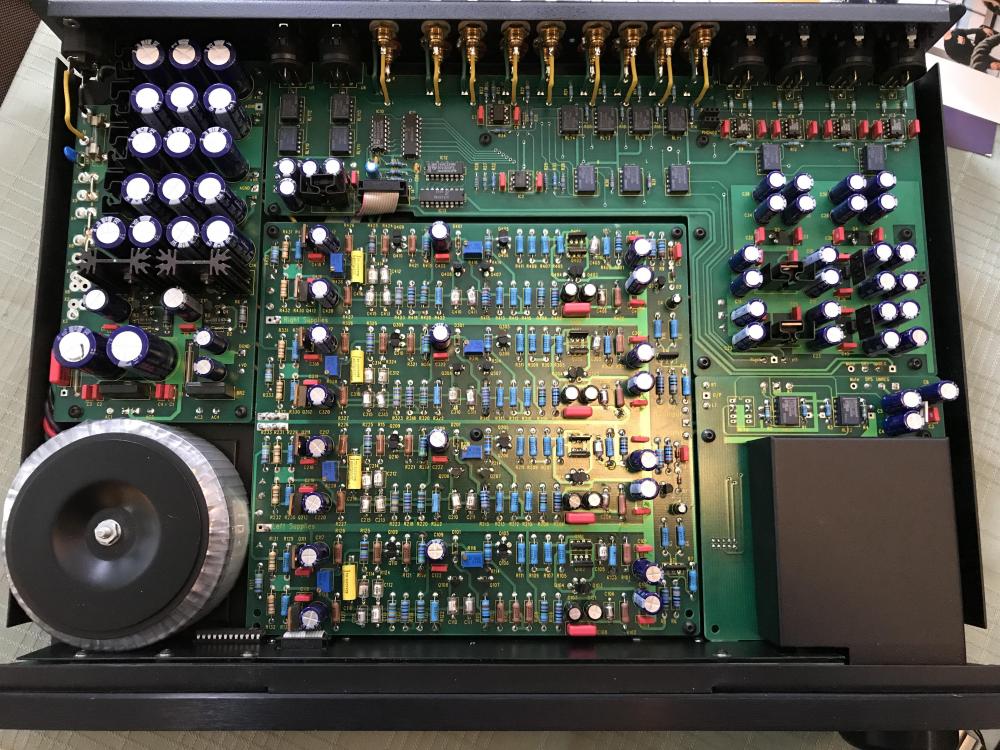

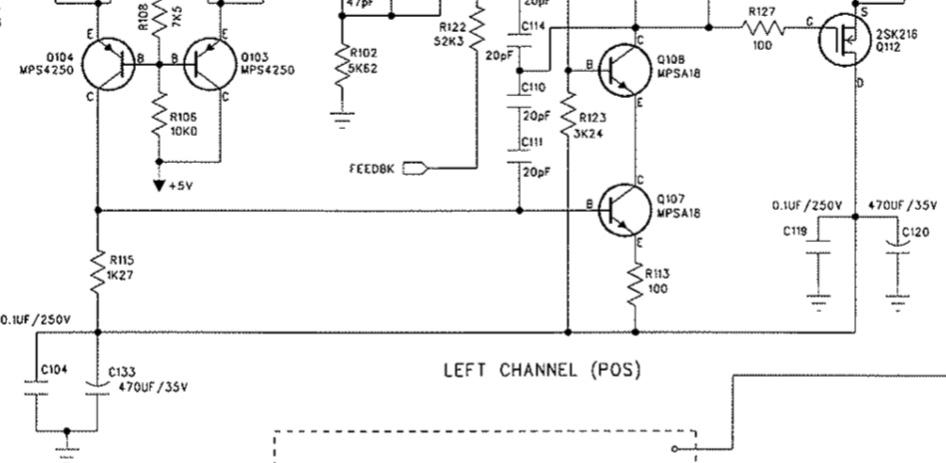

^ Yep. I attached some pics below. The last one with the 4 caps in a row next to the heatsinks are the caps that are running at 40V in the schematic. They don't appear to have leaked from what I can see (a bit of flux on the right side). From my experiences working on my Rotel RCD991, boards of this vintage are pretty easy to work on, so other than disassembly/reassembly, this might not be that bad. The schematic/service manual seems to be missing sheets 12-14 of 16, and I note the volume control (black box) is not shown on these, unless I am missing it. It is supposed to be a 60 step, and I assumed relay based as the volume control itself feels like an encoder. I haven't taken the front panel apart yet (not sure that I will) to see if anything is hiding in there in terms of electrolytic caps. Also, I was looking the amp section schematic over. This appears to be DC coupled. In the snip below (sheet 10), shouldn't there be a V- connection (-24V) at the bottom? I only see 1 rail being used, but filter caps on what I think should be the neg rail...

-

I came home from out of state on Sunday and noticed my preamp display was awry (L-R arrows flashing, mute on, front panel non-responsive). Last night I took a look at it and it seemed to return to normal upon running signal thru it (CD->pre->headphone amp). This is a Classe CP-50, probably mid-90s vintage. From reading the owners manual, the display I was seeing is what is supposed to be there after a power outage, but I thought after 45 seconds or so it was supposed to go back to normal? At any rate, I have it open now and think I will recap it. Most, if not all original caps are Nichicon VX(M), 85C, standard series, 2000 hour life (from what I can tell). This thing is a cap farm . My goal is to a) match the original size/lead spacing if possible for good fit, b) long load life, c) 105C rating. Target cap for me where possible would be Panasonic FR. A few questions: Is Nippon Chemicon any good? The two main PSU caps are 2200uf/63V with 10mm lead spacing. The two I picked were Nippon Chemicon KYB (10000 hr) or Nichicon UPW (8000 hr). I can't find anything worth a shit that has 10mm lead spacing; these are 7.5mm. I'm also pretty sure they are not snap-in as they are Nich. VX. For the above, I have some Panasonic TSHA 4700uf/63V snap in at 10mm spacing. I could straighten the leads and file as necessary to fit. Is going up to 4700uf too much increase? Note the 35V caps in a 40V circuit... haven't measured yet to see if it really is 40V. I'll replace these with 50V Nichicon UPW I'll probably have more questions as I go on. This thing has a lot of premium parts in it, such as (10) 2SJ109BL, 2SK79/2SK216, etc. Sounds good as well. Probably not as good as the Aleph P I had, but good nonetheless. Classe CP-50-TM Service Manual.pdf

-

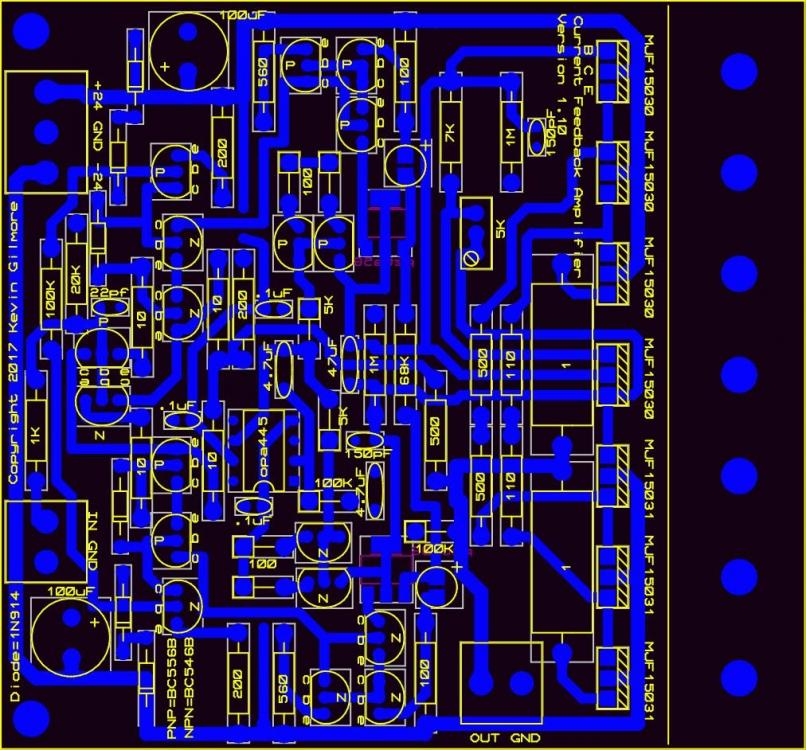

and now for something completely different part 3

Pars replied to kevin gilmore's topic in Do It Yourself

There is a 1K on the v1.10 board. Not on the schematic (hence the R? designation). There is also a 22pf cap on the board, also not on the schematic. These appear to be associated with the input as the 1K runs from the input connector and appears to connect to the 22pf. With Kevin's designs, you always go with the board markings -

50VA would be fine, though I usually use the 100VA Antek transformers. This is team overkill, after all EDIT: I also ran the sim I have with 35VAC input, and used 4K/2K for R7/R8 for 30V out. The voltages across the 47uf caps was 9V for the first one and 10V for the second. The 10uf had ~16V on it. This is a sim, which may not match real life, but I would think it would be close to actual.

-

There is a dynamic CFA2/3 as well. Now for something completely different... Sent from my iPhone using Tapatalk

-

You should be good. I’ll have to look at the one in my DynaFET as it is +/-30V. I think 35V is as high as you can get for the 47uf. I’ll take a look in a sim and see what voltage these are on a 30V supply. Sent from my iPhone using Tapatalk

-

They are shown as B stock... not sure if that means much for these or not?

-

Redco.com Sent from my iPhone using Tapatalk

-

Got one put together, but having a strange problem with it. The output voltages seem fine (and stable). However on startup, D1 flashes and then goes dim. D9 is brighter than either of the negative channel LEDs (D2 or D8). The V drop across the 150R are 1.51V for R1 and 1.62V for R2. Other voltages appear to be approximately the same. I'll have to remeasure the drops across the LEDs. The zeners appear to be similar (~8.9V). Any initial thoughts? Components appear to be in the proper spots. Since I was in a rush to get these made (seeed 30% off), I also hadn't noticed some placement changes vs. the layouts from Kevin, particularly the LED placement is for D1 and D9 were reversed from Kevin's. I have made some changes in my diptrace files since I had these boards run to correct for that and label placements, etc. EDIT: Found/fixed. Somehow I had put a BC559 in in place of an MPSA92 (Q3). Must have gotten mixed in my bag of MPSA92s somehow and I didn't read the labels when building it. Works just fine now (DOH!) EDIT2: This one is for Diptrace users. When I went back into the schematic for this, after making some changes for the LED placement, and to add a pair of 220uf with 5mm LS in addition to the 7.5mm LS caps that were there (Silmics?), I found that the V- net had connected itself to the AGND net (no V- net present). Fortunately, this was not present in the board file I had run. How does this happen? And it wasn't easy/straight forward to fix.

-

I got a number of hits searching on “pcb busbar”, including this one on stackexchange: https://electronics.stackexchange.com/questions/59735/creating-a-high-current-bus-on-a-pcb (Sorry, Hand-typed, hopefully works. Also, I’ve been out of town and didn’t take a close look at your pics). Sent from my iPhone using Tapatalk

-

Happy belated birthday!

-

Maybe just post them to the thread... Still not sure what all the interest is in this, but I confess to not having built one. The SS Dynalo is a better amp from what I understand. Or the CFP2... Sent from my iPhone using Tapatalk

-

Yes, dropping R14/R29 drops the bias level. Sorry for any confusion in past posts.

-

You should be OK, assuming you are using the right adapters (don't use the SA1349/SC33xx adapters!). There aren't really any voltages present there that would damage the JFETs, unless the Gate is wired incorrectly.