-

Posts

9,101 -

Joined

-

Last visited

-

Days Won

175

Content Type

Profiles

Forums

Events

Everything posted by VPI

-

I threw in a bid on an estate sale auction down in Texas to get the Veritas but everything is fairly nice. Especially for $15.

-

No doubt. Knocked the garage door out of its tracks the last time I tried to move the hose a few inches.

-

I need to make some turns and the thing is so unnecessarily stiff that every time you move one end the other end whips around and knocks the table saw over on its side. The blue Rockler stuff works perfectly with the Oneida so no reason to try to route a hose that has zero flexibility.

-

Yeah, not quite full yet.

-

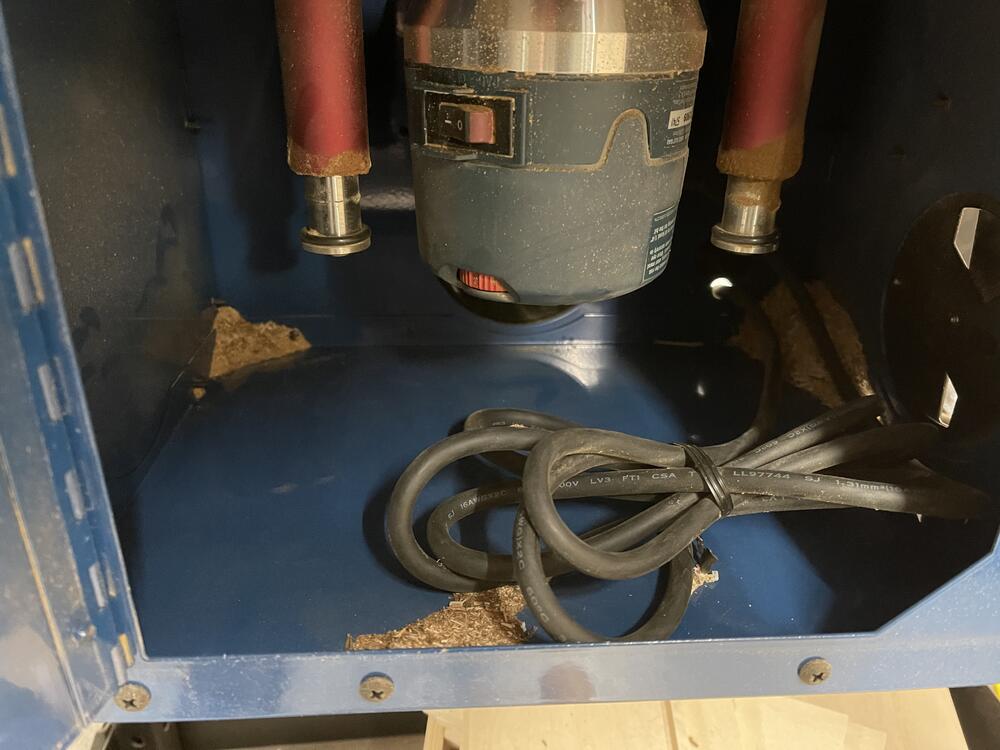

It definitely sucks better than the Dust Right. Before, after always being connected to the 1250 CFM Dust Right 4 feet from the router. And after 5 second running through a crappy Rockler flex hose.

-

Scratch that, the Oneida hose is the most unmanageable shit I have ever seen. That goes in the trash and back to the Rockler blue shit.

-

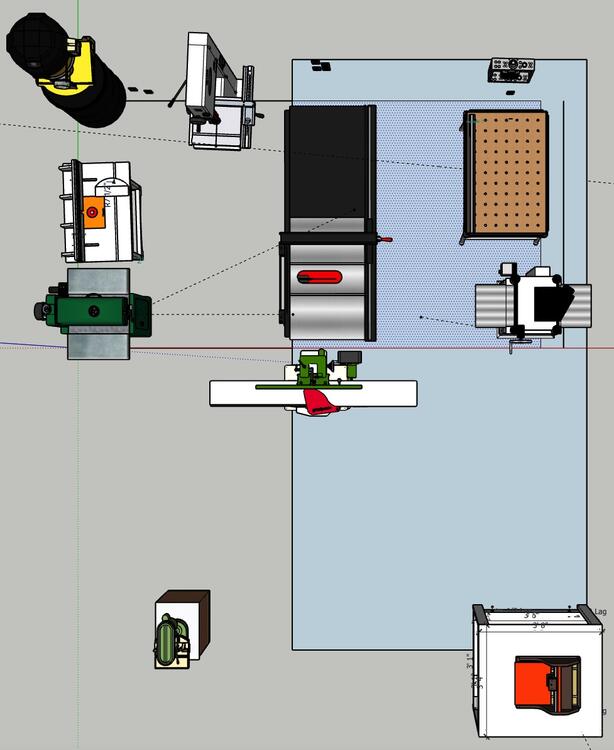

I just throw all of my sawdust away. Finished installing the Oneida. Still need to plan the two routes for dust collection. I am leaning at the moment to use the 25’ of nice flex hose that came with it to run to the tablesaw, jointer and planer. If I tried to run any PVC on that run it would only amount to about 8 feet of PVC and $100 plus in adapters etc. I will then run a 4” PVC across the ceiling to provide one drop in the middle for the router/drum sander and then two drops under the soffit for the drill press and CNC/Bandsaw.

-

Do you have a cabinet shop now?

-

Yeah, I do not think explosions will be an issue, but I am still tempted to stick to flexible hose as it allows for so much more flexibility in the tiny shop. Now that the rolling CNC is gone I am moving the bandsaw over next to the CNC which could technically allow me to get everything on one leg if I have a wye over to the table saw/jointer off of the main trunk, but that would require a 4” PVC dropping down from the ceiling to the floor in the middle of the garage.

-

Got my quote from Nord Fab. Only $6700 for the two runs. Looks like explosive static PVC will be the way.

-

I tend to use the Foreman more than the Castle, simply because it is more easily accessible. Works well enough for half-assed woodworking. Evidently iVac is working with Oneida to have a direct interface to allow for auto on-off with the stupid magnetic power switch in place. Just not quite ready yet. Trying to plan the ducting for the system. I am thinking two trunks: A. Bandsaw, Table Saw, Jointer B. Router, drum sander, drill press, cnc, planer. This will allow me to run along the ceiling and then have a long flexible hose to run to the Planer, which is in the middle of the shop, only when I am using the machine. Otherwise I have to run down the other wall with a separate trunk just for the planer.

-

Let me know when to subscribe. I need to see how you deployed the PVC for dust collection. Trying to decide if I go that way or spend $600k for Nord Fab.

-

Are you a paid influencer? Always have to check first. 🙂 Finished the uhhhh, finish for the tiny step stool. Holds my weight with no noises, so the little kids should be fine.

-

35 gallons I guess. I am hoping to get rid of both the 1250CFM and the mobile 750 CFM dust right units by running PVC across the ceiling to the side of the garage with the drill press, CNC and mitre saw and run 16’ of PVC down the wall toward the garage door with 15’ of flexible to the planer. I am hoping the turbo will have the balls for the long run on the planer, but I have some doubts.

-

I might be able to fit it on the wall over the dust collector. Remains to be seen after I get the new DC installed, hopefully next week.

-

During the summer I will typically have one running. Not really able to keep up most days. I will be adding the Mr Cool at some point, but if I get the bigger Oneida 35 gallon Supercell, the wall space may be taken that I need for the mini-split. All that is left it 3 days of applying Arm-R-Seal to wrap this step stool up.

-

Thanks. I would have preferred to do something bigger but most everything left out in my shop develops rust so I just put the cheap stuff out.

-

Mocking up a MCM step stool for the guest bathroom for the cousins’ kids after building another french wall tool holder this afternoon.

-

Those are some serious holes. My Castle and Foreman both put the screws well inside the holes, yours seems to get more of the meat of the board involved. How does yours adjust for different screw lengths?

-

For the short term at least, I threw up some French cleats and threw together a holder for the Clamp Squares and the Infinity Tools Woodworkers First Aid kit.

-

Has anyone used either the Omniwall or Wall Control products in your shops? Thinking of going with one of those behind the drill press table instead of French cleats.

-

Everything seems to be working and already dramatically better than the shitty Jet it replaced. So quiet… IMG_3037.MOV

-

Yeah I know, just did not want to offend Dr Wood.

-

Realize now I should have gone with less spalted maple and more hydraulic lifting table base in the drill press table. Heavy and awkward motherfucker. On an unrelated note, does anyone know the symptoms of a hernia?

-

Decided to scavenge pieces from the old drill press cart to build something with more drawers and a shelf to store various jigs across the bottom. Also needed it to be a bit shorter to limit lifting of the heavy ass drill press and fit the taller unit. New drill press will evidently be delivered tomorrow.