-

Posts

6,652 -

Joined

-

Last visited

-

Days Won

162

Content Type

Profiles

Forums

Events

Everything posted by naamanf

-

I’m holding out for the Red smasher.

-

Correct.

-

I have the Bosch, ordered the Milwaukee and a week later told it was actually back ordered. I had the Bosch in my last router table and have no complaints.

-

Hints on maintaining / improving my Stax SRM-T1S

naamanf replied to plaurids's topic in Headphone Amplification

Needs Blackgates.- 107 replies

-

- stax

- maintenance

-

(and 1 more)

Tagged with:

-

Not until I can get sheet goods with legs.

-

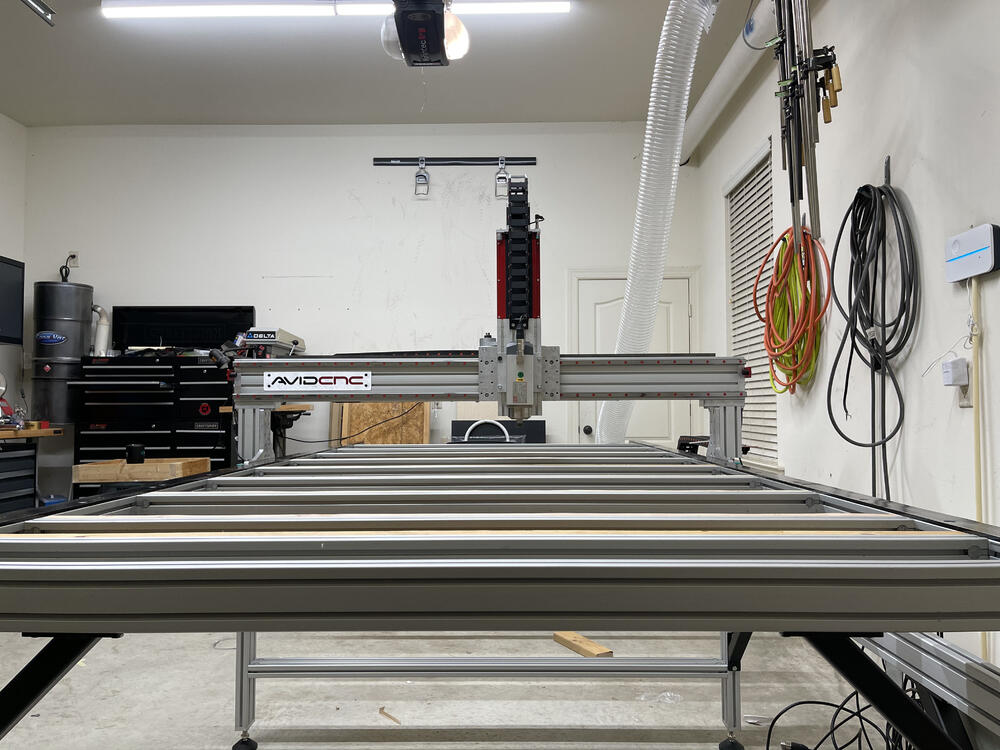

I almost feeling like I’m cheating at this point. Drawing some obscure shape, loading some wood, hitting run, and poof! Magic.

-

I’m not sure if my setup can do thread milling, not sure if it’s a controller or spindle limitation. Rough draft finished. Time to get some thicker cheap wood for a full mock up.

-

Good to know that trick works with aluminum as well. As I understand it there is a bit to get thread cutting to work?

-

MDF. Not wasting wood until I have it exactly like I want it.

-

Fixed. It was there in the preview. 🤷♂️

-

Test run on what will be a Stetson and sword holder. Figured 36” would be large enough, I guess not.

-

I’m sure we could come up with some good stuff. I’m seeing that drawing the part is the smallest part of the battle. Converting it into efficient CAM and choosing the proper tools/speeds/feeds is the challenge. Good thing I’m now at the point where I have to time and resources to do what I want.

-

I got lucky and someone had them already made up for a different tool holder. If I had to do it, I would just trace, scan the trace and then do a bitmap trace in VCarve or maybe find the same tool in Inkscape.

-

Wouldn't surprise me if they start selling them soon. They already have Traegers.

-

Threw together a tool board in VCarve. In hindsight I could have done a better job with the space but it works for now.

-

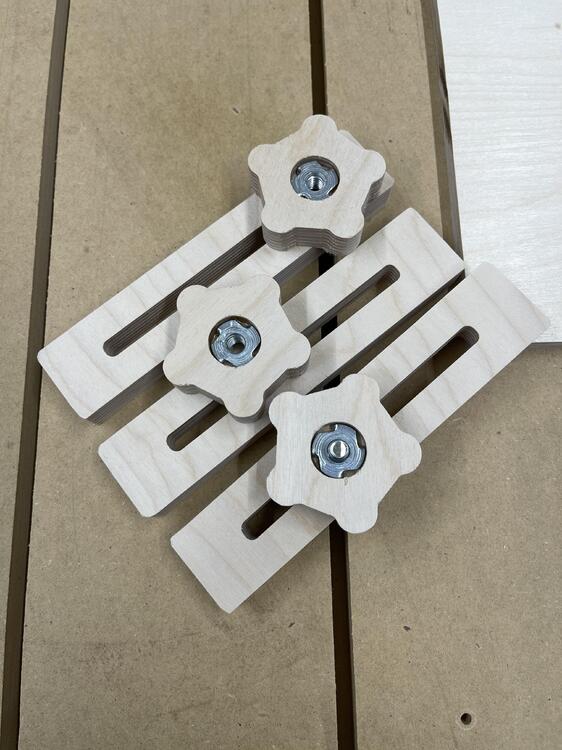

Steve knows my hobbies well 😂 Made some hold downs. Seems a compression bit is key when cutting plywood.

-

Put on and cut a spoilboard with T hold down tracks. I’m seeing that work holding is a large challenge. For some reason I see a vacuum pump in my future. And a ATC, pulling collets off and on is lame.

-

Easy for my drilling robot, just need exact dimensions.

-

Drilled four holes. IMG_3596.MOV

-

-

Having a large cabinet humidor has been my want list for a long time. I’ve actually been thinking about making one for a while. Local large commercial lumber supplier actually stocks the Spanish cedar so getting material shouldn’t be that hard to make it. I just need to step up my design game.

-

They are a lot cheaper than new fingers.

-

It keeps the material pressed down on the table and the wheels are angled to keep it pressed against the fence. Basically does the same thing feather boards do, helps make straight cuts and adds some safety against kickback.

-

Put these stock guides on today and cut some 15’ pieces of ash to make stiles and rails for cabinet doors. Worked pretty well, real test will be ripping larger sheets.

-

I’ve been happy with the Freud Industrial blades I’ve bought.