-

Posts

13,716 -

Joined

-

Last visited

-

Days Won

39

Content Type

Profiles

Forums

Events

Everything posted by luvdunhill

-

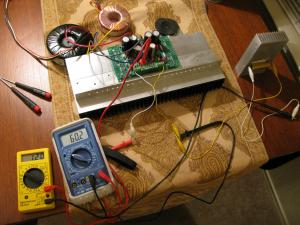

still playing with it. Starts out with 0.1 offset gets down to less than 0.1mV (the resolution of my hand held DMM). This is the trimmers set at 500 and not touched at all. I'd say they are sorta not needed. Much better than my Dynahi version. I'd say these heat sinks are rather perfect, and the long hours of matching are rather worth it. The minimum bias with the 20K pot is 750mA. Lamers may need to up this value. Accidentally had the bias at 3A for a bit... oops. Running at 1A now. The transistors in the buffer are hot, I cannot touch them for more than a second.

-

it works

-

Muse Model 9 Signaure. Wait... crap. I'm half tempted to buy one of the upper end models that will also play SACD... but haven't found a good deal on one and have to free up lots of cash to afford one...

-

Bigger than 19" x 13.77" x 6"? If so, then I must make mine bigger!!!!1!

-

my SACD's arrived... I got an extra one too, but it's a duplicate of one they already sent me :/

-

Jacob: One more thing. You can fit in a three pin Molex connector (similar to the one below C13A) right below C1B, oriented perpendicular to C1B. Connect one pin to ground, one pin to R55 and one pin to R56. Then it would be easy to adjust the gain remotely. Of course a DPDT (or 4PDT) relay or something to keep the signal short here in the feedback would be cooler and fantastic if integrated into the UberController project!

-

Reks Fiat

-

now that's colloquialism failure

-

turn a blind eye

-

that was supposed to be a funny

-

what about the inductive component of the load, after all you're driving a large transformer...

-

check out their posts and see for yourself try this Google Search: "offline." "banned." site:head-case.org

-

I my opinion, any amp used as a speaker amp should have output protection, preferably something active. However, if you want to go passive, a simple capacitor / resistor zobel in my opinion is inadequate for what you're doing and an inductor (RLC) like amb recommends for the beta24 would be a safer option. Since a beta22 doesn't have any output short protection, maybe an active speaker protection device is a better choice.

-

good if you drive 2 miles to work, bad if you drive an hour to work.

-

never heard of any inert metal, so I dunno

-

maybe it has a greater effect on lower level pain signals ya know, it starts clipping at some point or buffers get overflown..

-

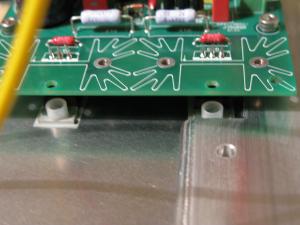

well, after tapping 8 holes at #6 instead of #4 , I had to order some parts from Mouser and they just arrived. Namely, the four #6 standoffs and the nylon clad steel screws. Since I cannot fit a shoulder washer anymore to isolate the MOSFETs, I decided to try some nylon. With these fancy screws I cannot get as much torque as using just plain nylon unfortunately, as the inside screw starts to spin a bit... So, I may go back to pure nylon... Anyways, sorta got lucky this worked out. Perhaps there are some other creative solutions, but I couldn't think of any that didn't require tapping and milling my heat sink and/or bracket. Meters show ~+-30V drawing 1.2A. Things get rather toasty Now to get the FETs mounted to the DynaFET boards and get this show on the road!

-

Think of it this way... That cartridge didn't cost you $5K, and it's doubtfully worth $5K on the used market... There, does that help?

-

Jacob: Would you consider adding a way to mount a small PCB in place of the input transformer? I'm thinking similar to what Nelson Pass does for the UGS boards in his preamps. He uses two banks of DIP pins to connect the daugherboard and you'd route up the necessary I/O signals up via these pins. I have a solid state SE to Balanced design I'd like to try down the road a bit, and it would be nice to just snap it into the boards.

-

I understand, I just don't have the equipment to convince myself one way or the other (and trust few people's word on the subject), so I figured as short as possible and definitely less than 6" will be what I shoot for.

-

6" is a rather standard recommendation for I2S. There is a line driver circuit by Elso Kwak around if you want to go longer, but IMHO it just invites many issues I don't want to deal with. Now as you said, whether this is relevant, I don't know, but seems like a sane place to start.

-

well, remember this will be digital, not analog connections (think I2S).

-

Definitely hardwire. I wouldn't run the lines more than 6 inches, without a line driver circuit. The real question is how much room is there in the case for a few power supplies and what not. Have you dug up all the threads that reference this from DiyA and HF? If so, I'd like a short list of them to read over.

-

at least the cable elevators are still there!

-

Tkam, do you like your TomTom 730? I'm considering either a GPS or upgrading my wife's Blackberry to an iPhone.... I'm considering the Garmin Nuvi 760 as well.