-

Posts

726 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Events

Everything posted by chinsettawong

-

Which part do you like to see? These are my stator and spacer.

-

Imbalance problem often comes from a small arc spot on the diaphragm. First, I would open the driver up and check the diaphragm. Most of the time, the arc spot is pretty obvious. You need to check which side of the diaphragm is coated. A simple way to check is to use your finger to lightly rub the diaphragm. The side that is coated will leave a trace when you rub. The arc spot normally only affect the coated side. Since the coating material stays on the surface of the diaphragm, if the spot isn't too large, you can just wipe the spot off using a lint free cloth. When you rub, the coating on the diaphragm recoats itself. That's how I fix my driver. However, if it still doesn't work, then I will recoat the diaphragm. But when I do that I normally recoat the diaphragms on both drivers so that I'll have equal sound.

-

Nicely done, Kerry.

-

That's so beautiful.

-

I can fix it for you.

-

You can also put a thick coat of woman's clear nail paint over the nearby copper traces. The nail paint is a good insulator.

-

Whatever your driver problem is, I might be able to help you.

-

Why would you want to have 007 drivers in a 009?

-

Sorry, I don't know how to use a scope. Anyway, I learned about the leaky resistors from reading this thread. I then changed all my PRP resistors in the batteries to a local brand resistors and the problem was fixed.

-

You hear noises - lots of noises.

-

In my case, it's the problem of leaky resisters.

-

Have you changed out all the resisters in the batteries? On mine, I changed all the resisters and the problem was fixed.

-

That's DIY T2's chassis, isn't it? Nice work.

-

Very beautiful!

-

Count me in too.

-

Hi Vinh, I'm also in Bangkok. If you need any help, just let me know. Wachara C.

-

Really like to see n3rdling's HE90 Clone.

-

Wow! Beautiful!

-

The servo works very well now. I adjusted the output to around +13V from cold start, turned off, and put the jumper of the opto on. Turned the amp on, and the servo started to work immediately. It's very nice and stable. Thank you everyone for your help.

-

Thanks! I'll try and report back tonight.

-

My servo doesn't seem to be working. Do I put a jumper on both the opto and the opamp or do I put it on either one?

-

Fired up my Carbon last night. Adjusted the current to 20mA but back down to 16mA at the moment as I'm afraid that my transformer can't stand it. Being lazy, I utilize the power supply and chassis from my KGSSHV. So I should consider it as an upgrade. I'll buy a new transformer and adjust the current to 20mA later. The amp is running at 450V. Even at 16mA I can feel that it's running a lot hotter than my previous KGSSHV. The amp sounds wonderful. Thanks Kevin for sharing this wonderful amp design.

-

Too much meat.

-

Give me your address and I'll make and mail a few to you.

-

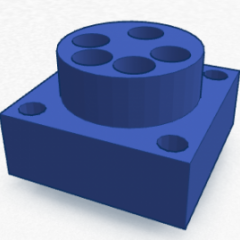

Can you get access to a 3d printer? You can print out the plastic part with a 3d printer and use the pins from XLR male connector. I've done many for my DIY headphones.