-

Posts

8,567 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Events

Everything posted by Pars

-

Yes, looking at the schematic, I would agree that even 20V would probably be OK. I'm using 35V for the 47uf parts in mine, and 25V for the 10uf currently, but that is just what I either had or sourced.

-

C7, C8, C9, C13 for the 47uf C3, C16 for the 10uf Assume a supply setup for +/-20V output, 2x23VAC input

-

Just an fyi, but the Excel BOM that I have has 25V tantalum caps, while Kevin stated 35V in this post: Note the part number provided above is actually a 20V part. Correct part numbers would be something like 581-TAP476K035CCS and 581-TAP106M035CCS for the 47/10uf parts respectively. Sorry, just getting an order together for the remaining parts to finish one of mine (v.42 or goldenreference4) boards. I haven't done a spice model or analysis to see what you really might need here, and I assume a number of these have been built with no problem according to the spreadsheet I had (which I can't find here on HC anymore).

-

CLOSED: Alpha/Song Huei Potentiometer Group Buy and TKD Attenuators

Pars replied to cspirou's topic in Do It Yourself

Paid. Thanks! -

If you go back a few pages, I posted something about some that I have marked Burans or something like that:

-

Kerry, What is your impression of the Alpha pot since using it? Taking a quick look I didn't see anyway to get the TKD 601 and the Alpha to play nice together on the same board. If it wasn't for that damn tap or the way they did the pin order on it...

-

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself

Yep, same here. Can edit f and g, but not h. Put me down for 3 of the all 3 pcbs (column h) -

Kevin's formula is more accurately shown as ((R8 + R7) / R7) x 10

-

The potentiometers are continuously variable pots, whereas the attenuators are stepped attenuators and made up of fixed resistors, with a fixed number of steps, so a fixed jump between steps (2dB on many of them). Other examples of stepped attenuators would be Dact, Goldmund, etc. These probably track better, but the fixed number of steps could be a problem depending upon the volumes selected, and so on.

-

Happy Birthday!

-

Remove it I would think... would have to check the schematic

-

If you get in a bind for prototypers, always happy to help.

-

You got that right. A great man, and all sports stars really have him to thank for their obscene paychecks and opportunities. I remember my dad always liked him, disliked Nicklaus (because of Nicklaus beating him regularly) and liked Tom Watson, probably because of Watson beating Nicklaus. I ran into him in the parking lot at the Ameritech Senior Open back in the '90s (with my dad) and recall how personable and approachable he was. RIP.

-

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself

After confirming the pinout of the Alpha 4-gang pot, I don't see any way of integrating this into the 3-pot board. The 2nd row of pins (tap) from the left are electrically active, so cannot touch any existing pad on the board. No way to do it in my playing around with the board, short of giving it its own space on the board. Add to this the difficulty in sourcing the part. I am going to go with what I have, and will generate what I hope are the final gerbers in the next couple of days. Seeed has not responded to my email, so hopefully they are fine with the slots for the 16 pins on the 4CP2500, and fine with the additional 2 slots to mitigate drill overlaps. Slots should be cut before any other steps on the board, including drilling. All slots need to be thru-plated, so Michael, please note that to Seeed when you place the order(s). -

I'd agree on the assessment regarding the Song Huei pots, as they even share the numbering (2142G) as cspirou noted. They also give a complete schematic matching Kerry's board layout. Since I believe he built one, I would assume it works Other than the TKD CP601, this pot is the smallest of the lot (TKD CP2500, Alps RK27), so keep that in mind Kerry before you offer to use a different pot. I hadn't heard much in terms of reputation regarding sound quality of the Alpha pots vs. the RK27 and the TKD CP2500 (or 601). I know that I have liked the one CP2500 that I used, quite a bit better IMO to the RK27. I also hadn't realized that Justin was using these for a time in the GSX, but he also is crazy enough to buy 1000 at a time

-

Can't read the CAD files (no software), so no help there. Datasheet says 1.57mm/0.062 which I'm sure you saw. You have some interesting projects going on!

-

OK... Normally, #1 pin is the lower left (which from the bottom would be the upper left, I guess). The "schematic" Alpha has on their website labels the pins 1-3, so I assumed that pin 4 in each row was the open or loudness or whatever pin. I can't find any mention of this on their website, and they don't seem to have complete datasheets. Seems like a typical CA company, with their website and all Where can you actually buy these things, as they have a 1000 pc. min order?

-

^ That doesn't match what Kerry did on his boards from L-R top (or front): 1 - 2 - 3 - 4 Gnd open output input (wiper)

-

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself

Nope. Wire as labeled on the board I1-I4, so normally L+/L-/R+/R-. O1-O4 go to the board inputs in the same manner. Or be different and do R/L -

Yeah, I hadn't looked at that. Isn't it $2.26 for a package of 100 Guess not...

-

Happy Birthday Jim! Hope you are enjoying things in Florida!

-

Good info from Gordon Rankin. Kind of a big leap of faith with the writer making this statement however: Bringing it all back home, the iFi iPurifier 2 likely improves the sound of the Sonicorbiter SE because it minimises transmission errors by making lighter work for the Mytek Brooklyn’s USB receiver chip. I would think that the purifier may be changing the error(s), but whether it is actually minimizing anything can't really be determined without looking at it as Mr. Rankin does.

-

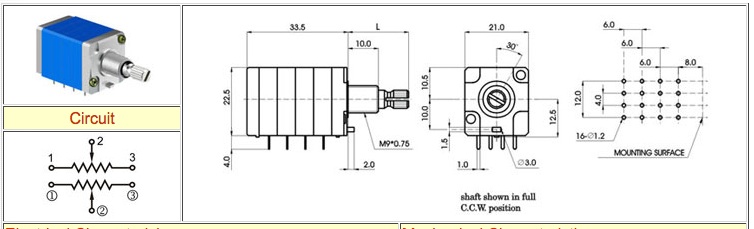

From looking at Kerry's layout, it looks like he is connecting pins 1 (gnd), 3 (output?) and 4 (input) on the pot. I assume that I am looking at the right pot (Alpha 21mm 3RP-2142G, from Alpha in Oxnard, CA)? There is also a Taiwan Alpha and a Korean Alpha, but the pots I find from there aren't 4-ch, look nothing like this one, etc. The data I found on the CA Alpha company website just shows pins 1-3 on their schematic diagram, so I assumed the 4th pin (right side row) were loudness or unconnected. I also made the assumption that the pin numbering starts from the left lower corner: 13 14 15 16 9 10 11 12 5 6 7 8 1 2 3 4 If anyone has the correct datasheet or a link... this is what I was looking at. http://alphapotentiometers.net/html/21mm_pot_4.html