-

Posts

13,717 -

Joined

-

Last visited

-

Days Won

39

Content Type

Profiles

Forums

Events

Everything posted by luvdunhill

-

I prefer scat to cat.. but both to cat scat.

-

Did you at least ask Larry this time?

-

Cool - actually it’s not walnut but made to look like it. I did some experimenting and found that a 50/50 water to acetone applied at the second to last standing step opened the pores and allowed the teak to take a tinted oil finish. I was thinking a varnish would be nice.

-

Yeah that’s what I did. To be honest I was lazy.. I found a really nice place to get a nice slab cut ((https://berdollsawmill.com/slabs/) but I am running out of time on this project so I got scrappy.

-

It’s a mostly alive edge.

-

I am working on building a bathroom and played around a bit with finishing this floating shelf… probably obvious what kind of wood it is but I experimented with opening the grain and using a tinted danish oil.. will try a clear coat when I get the sink roughed in. Pictures are after finish and before.

-

Would anyone be able to 3D print two custom sized washers/spacers in yellow for me?

-

-

So Brent probably won’t be okay?

-

I was curious if they added natural flavors to the roasting process for example

-

Dan, how are flavors added traditionally to coffee? For example our local grocery chain has something that is sold as: a medium bodied coffee with sweet cream and vanilla flavors inspired Inspired by the sweet, decadent flavors of a Tres Leches Cake.

-

What about blutarsky? When is this thing

-

Just for knowledge acquisition - water based stains go on before an oil finish but oil based stains can go on anytime (including between coats?) I need to grain fill a bit so my worry about adding a stain on first is that I blow through it as I am trying to fill in the pores with the oil finish. I would prefer something I can apply anytime hence the question about a tint in the oil finish.

-

Thats correct. First photo is raw after the repair and second is one coat of the linseed finish. Think I need to go darker quicker without applying more finish coats..

-

Hi all! I am repairing a piece of walnut that broke off and am in need of a stain to darken and color match. I am not sure what the best approach might be - tinting a linseed based oil finish or applying a water-based stain and then finishing with the above oil based finish. Any suggestions?

-

nice router table!

-

I dunno, one time I saw you put the wood in the wrong direction. Just saying.

-

Uh no. I see now. Sadly none at Woodcraft.

-

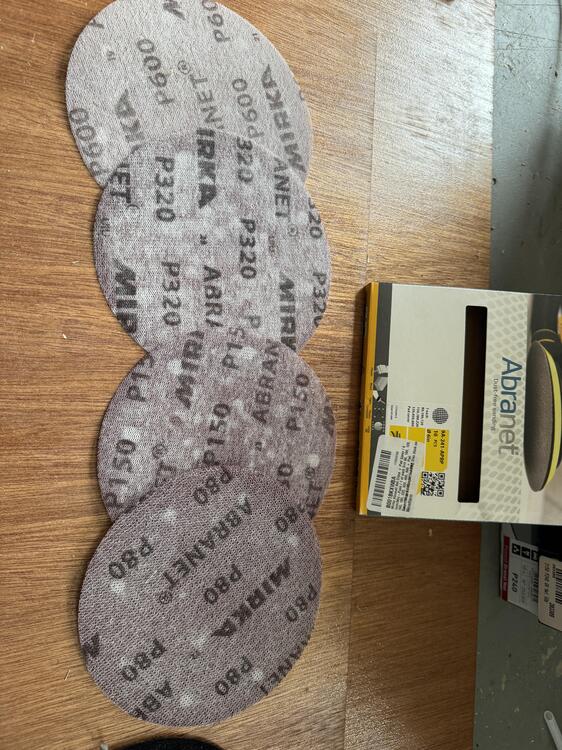

I went team Head-Fi and found the cheapest thing that I am here to tell you is amazing. It seems to be good enough for my little project. I wish the holes lined up on the pad saver so dust extraction would be better though. Making a trailer storage solution for a sailboat using marine ply and epoxy.

-

There isn’t a multi grit option in smaller quantities - ya gotta pay $70 a box.

-

Went to an acquaintance who has like all the green tools and compared the ETS EC 150 to the regular one. Actually preferred the non EC and just picked it up in 3mm. Super annoying there isn’t a mesh/net disk assortment. Specifically having an issue with west system epoxy clogging up the regular paper backed disks and looking to try something new out.

-

Enjoy some music, make me money - shameless affiliate plug

luvdunhill replied to skullguise's topic in Off Topic

The obligatory MOTMOTMOTMOT -

Nice! Definitely a step up!

-

Very cool. Needs more scrolling though.

-

Is there a way to define an area and have a pattern design filled in that area, or are these designs just made for these specific dimensions?