-

Posts

138 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by penmarker

-

unbalanced/balanced to balanced tube input

penmarker replied to kevin gilmore's topic in Do It Yourself

Ha, the mica insulation for the 100V section made me nervous. Its great that I shouldn't worry about it. -

unbalanced/balanced to balanced tube input

penmarker replied to kevin gilmore's topic in Do It Yourself

On a scale of 1-10, how ok is it to use mica insulators instead of ceramic for the HV section? -

This thing is comparable to one of those OBD throttle controller that you plug into your car so you'll only need to press half the pedal to get full throttle and tell your friends you got 20+hp.

-

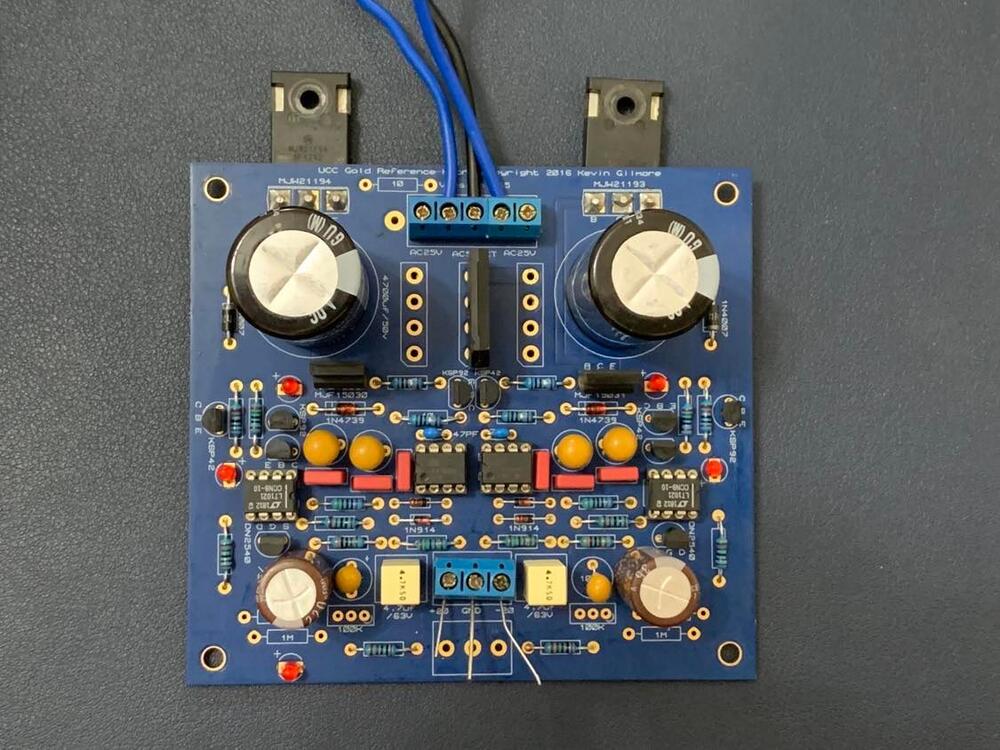

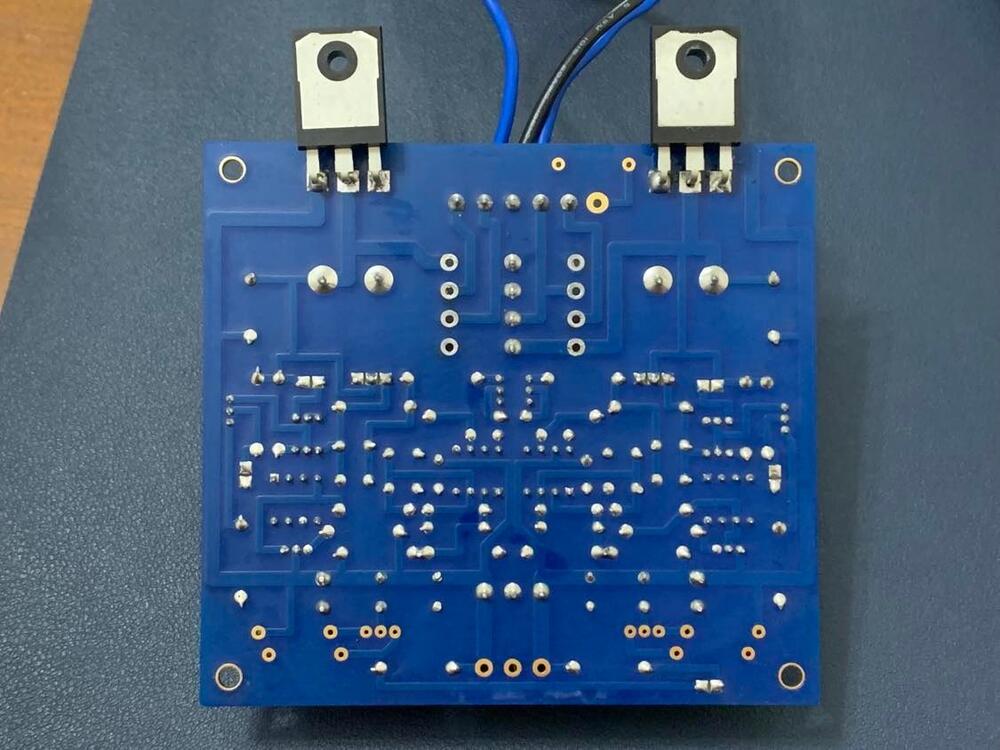

goldenreference low voltage power supply

penmarker replied to kevin gilmore's topic in Do It Yourself

Sounds all good then. My GRLV runs probably around 40-45°C but the case for PSU only has vents at the top panel and no bottom panel holes (hard to convect heat if there's no air inlet at the bottom). It's not as hot as Dynahi heatsinks. -

goldenreference low voltage power supply

penmarker replied to kevin gilmore's topic in Do It Yourself

What's the normal temperature for the transformer and PSU of a pair of GRLV powering Dynahi? -

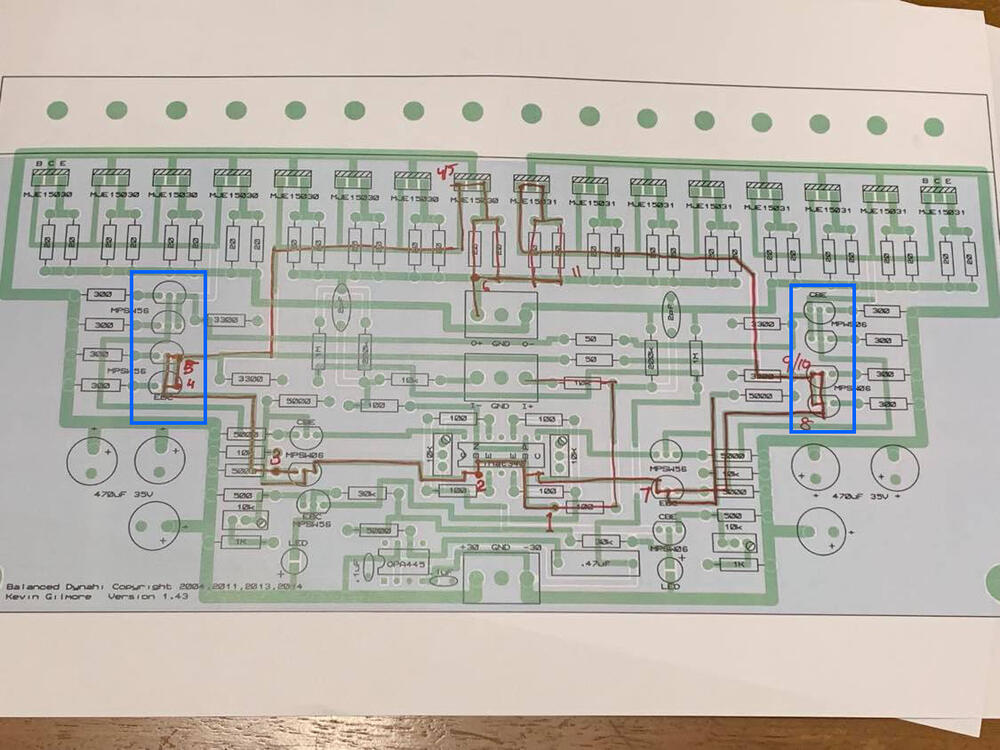

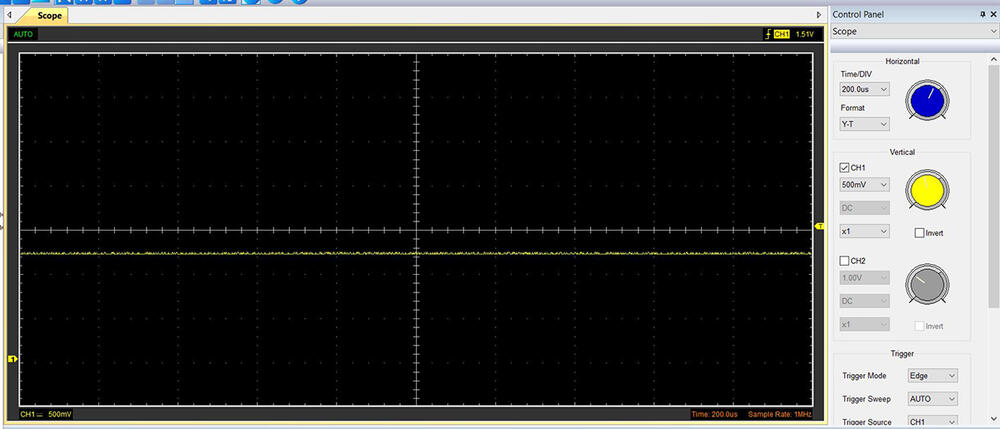

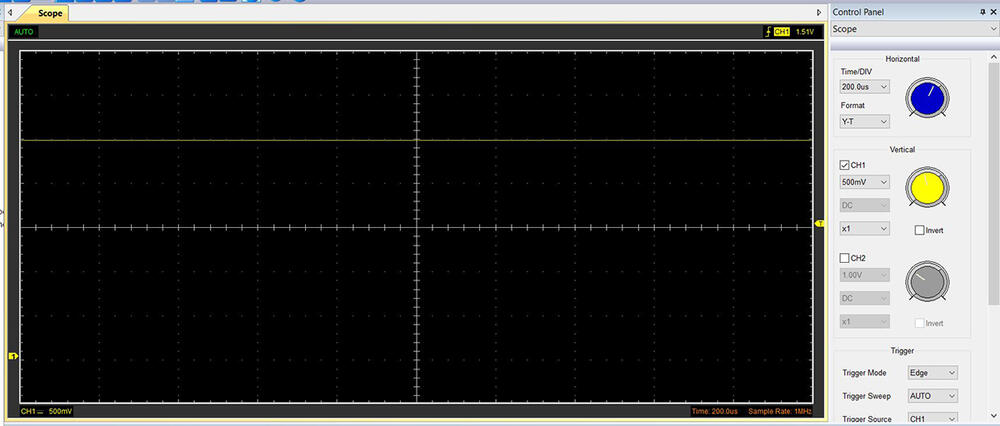

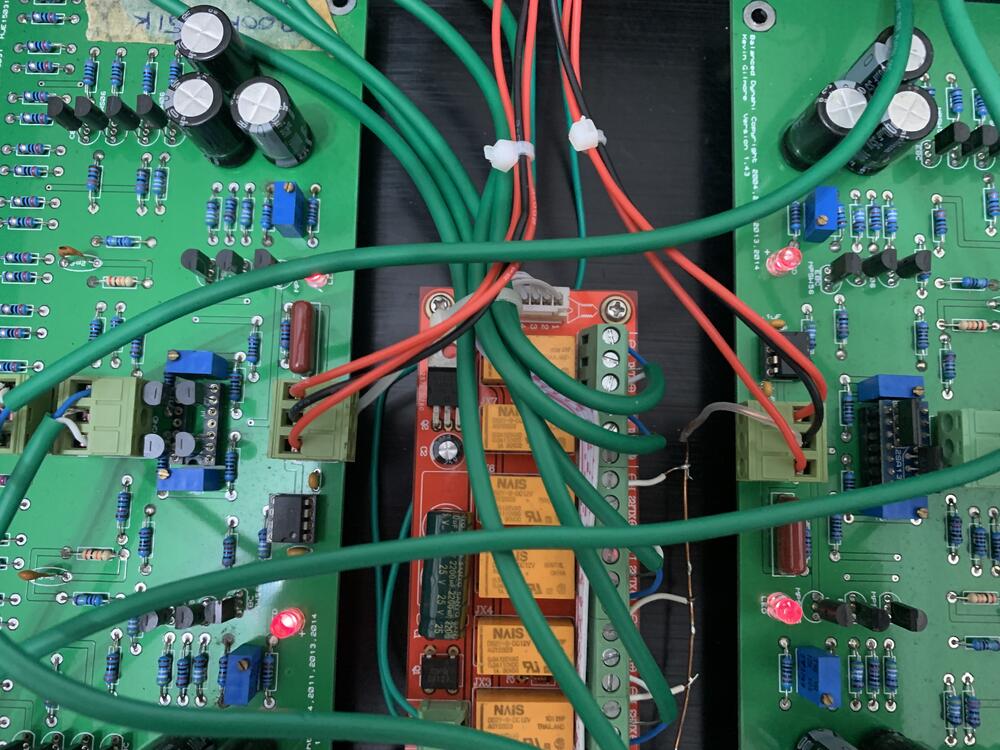

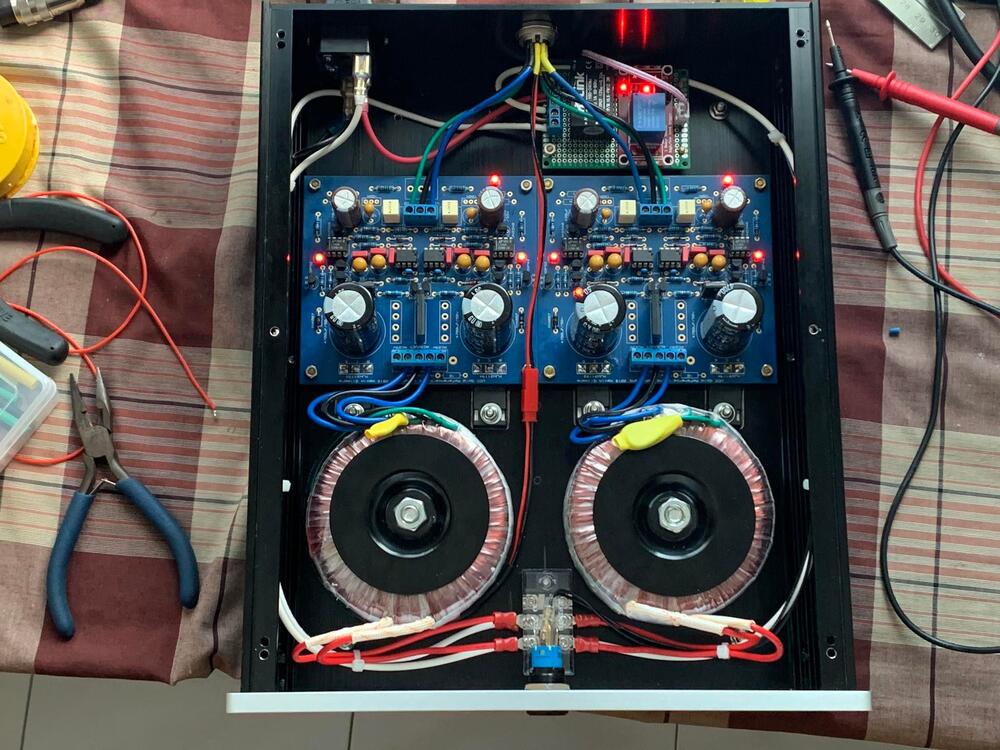

I've replaced all MPSW56/06 with matched using circuit from here. I've also replaced my LEDs with matched LEDs. Previously the LEDs were correct at 1.7Vf but they were rated 20mA while the new ones are only 2mA. The amp still has that intermittent rustling noise when warming up but volume was quite low. I've also realised the high pitched turn off sound is not normal after reading back like this guy. Since I'm not in a rush I spent a few days tinkering with the biasing and offset. With lower offsets between -O/+O to ground, there's no turn off high pitched noise on se output. With lower offset between -O and +O, there's no turn off high pitched noise on bal output. Lower offsets during turn on mitigates turn on thumps but it will affect readings when the amp has warmed up to temp (also the high pitched turn off noise returns on either se or bal out). All 4 VR pots on the board will affect every reading that needs to be checked. Finally settled with a setting that has soft turn on thump, no high pitched turn off noise, lowest rustling warm up noise on my very sensitive Final Audio Pandora Hope VI with 16ohm impedance and 105dB sensitivity. On HD650 and HD525 there's no noise floor. My throwaway portable Oneodio Pro-50 has a medium noise floor and very low warm up noise. The only downside about this is the +ve and -ve biasing voltages are different 750mV and -740mV. Being only 1.33% difference, I don't think I'm too worried. All in all such a great project. Maybe my next Dynahi SuSy I'll just use MPSA and see how it runs.

-

The ground for SE output goes to one of the output ground. All the grounds on the board are on the same plane. For SE in you'll need to tie the L- and R- to their respective grounds.

-

Thanks. I’m currently using MPSW parts from eBay. My assumption is they’re genuine but it’s been years ago so I can’t check anymore. Bought as a lot for 06 and another lot for 56. I matched them by HFE with a diy transistor tester.

-

After replacing the input devices with K170/J74 I'm still hearing noise from the single ended out (with sensitive headphones). It sounds sort of like a frying sound that comes and goes. I probed the amp with my USB scope. The signal from FET devices and the first transistor is very clean (Q4, Q5). I found the noise came from the transistor pairs before the power transistors. Not sure what causes this. Is it because they're not closely matched? Is it dirty power?

-

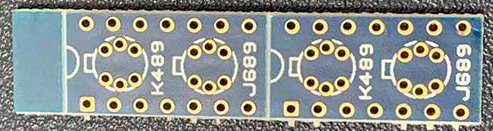

Yup, I'm using Mill Max sockets for the THAT340 so swapping them out was quick. I was thinking about coupling them together so each pairs will be same temperature. Left it on for a while and touched the jfets but it seems they stayed cool. Is their current draw way lower than what we would find in speaker amps?

-

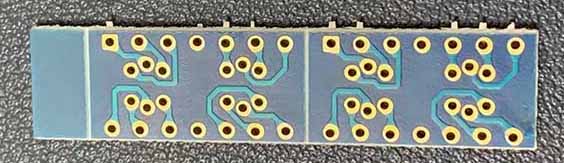

Just found these k849/j689 adapter boards with incompatible traces from last time's group buy. I could probably adjust these instead to make them pin compatible with back to back J74/k170

-

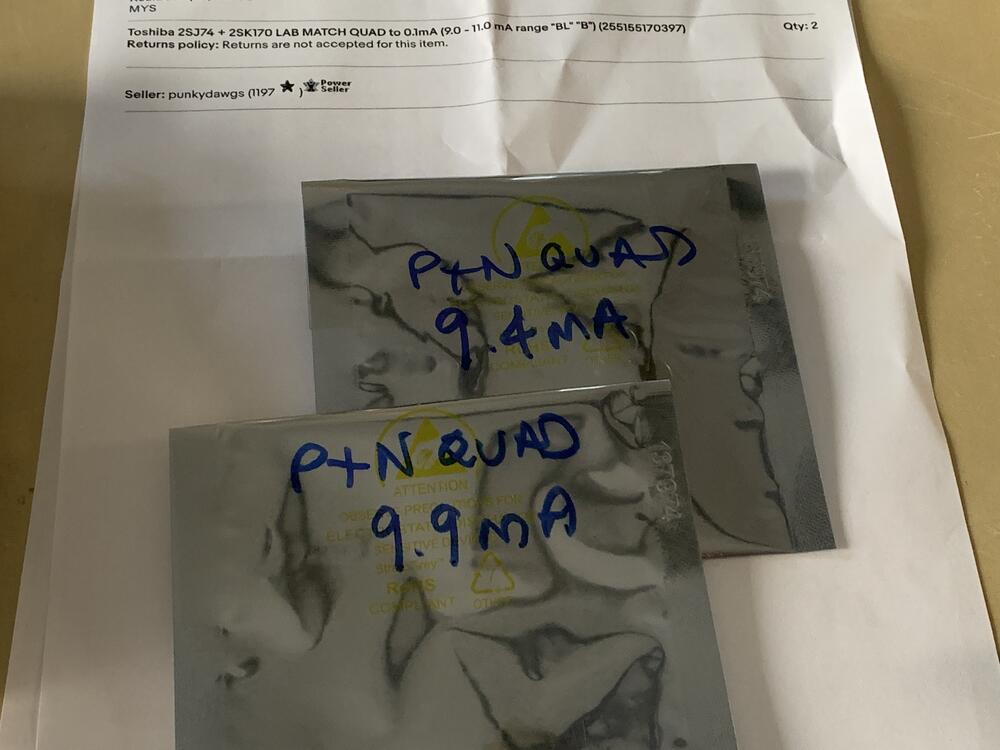

Received my j74/k170 from punkydawgs the other day. He even included some metal cans to thermocouple the packages. Installed in my Dynahi today (left channel shown) and did some bias checks. All look good. The difference between left and right is just a bit perceptible I’ll fabricate some adapter board with protoboard if feasible so I can heatshrink the packages back to back. If can’t I’ll just use the included metal cans with some thermal paste.

-

goldenreference low voltage power supply

penmarker replied to kevin gilmore's topic in Do It Yourself

Glad I got the Lumberg SV80 and KFV80 connectors. Smooth like butter and low profile. 329587661_5880443992073835_6229699499347506353_n.mp4 -

goldenreference low voltage power supply

penmarker replied to kevin gilmore's topic in Do It Yourself

***Edit 2: Seems that the BR was faulty, it works fine now. Can someone suggest me where I can start troubleshooting? I have a GRLV set for 30V that worked previously with a dual transformer. I got myself a center tapped transformer and adjusted the bridge rectifier accordingly - only one in the middle. Wiring in is correct for a center tap. The GRLV blows a 1A fast blow fuse every time turned one. Left side +30V has time to reach +30V before the fuse trips while the right side -30V will not light up in time. Transformer is 100VA 30V - 0 - 30V The bridge rectifier is reused from the same board **Edit Here are my findings If I connect only the center and right terminals, the whole board works fine. + and - 30V on the outputs If I connect only the center and left terminals, the board reads wrong and the bridge rectifier heats up. I think the BR is toast from desoldering. I'll try taking it out and testing -

We can weaponise it and make people think god is speaking directly to them.

-

I'd experiment with some sticky residue remover like Goo Gone for the leftover adhesive. Isopropyl Alcohol could work too. I'm not sure what the surface finish is so as long as its not some strong solvent it could work yeah no problem.

-

That's the safest choice I agree.

-

These came from china so there are no datasheets. I was planning to put these in a new Dynahi but I've decided to get the momentary counterpart to trigger a relay instead.

-

Thank you, that made perfect sense. This switch is rated for 220V and I was planning to use it as the power switch. A trigger for a relay sounds a lot more safe it seems.

-

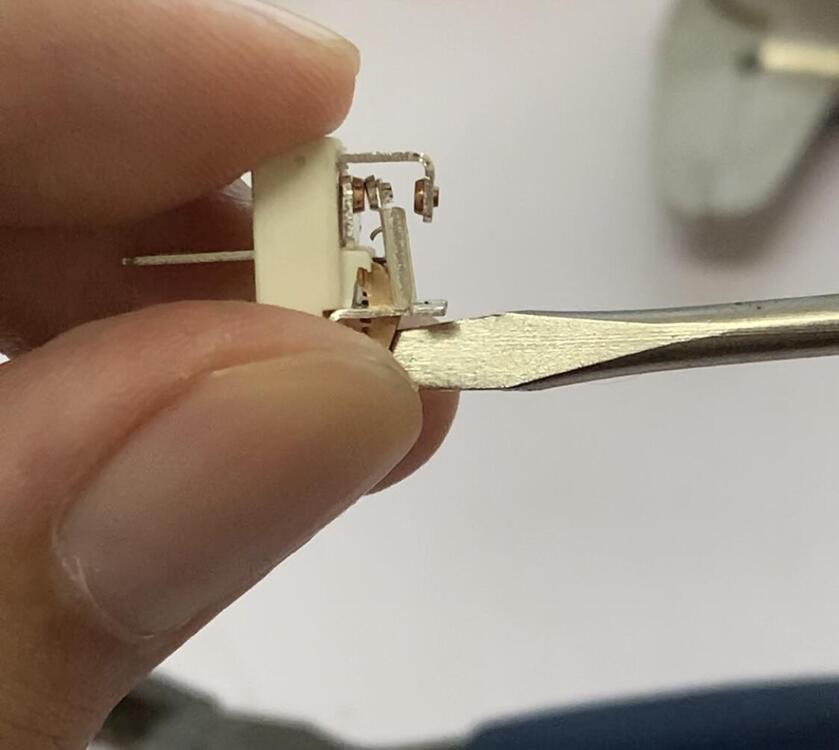

I’ve bought some of those common anti-vandal push button switches and took one apart to study the mechanism. Are the contactors big enough for a headphone amp?

-

I switched opamps with no effect, then I switched out my SA1349/SC3381 between L and R and I can hear that the scratchy sound is now on the left channel. It is mostly audible while the amp is going up to temp, but it's hard to reproduce and its long periods between noises. Seem to be random. The other channel also have that scratchy sound but at a lower level, I can hear that on sensitive headphones. Well at least now I know what's the problem now.

-

Tip of 1/4" headphone cable plug broke off inside a locking Neutrik jack

penmarker replied to jpelg's topic in Do It Yourself

No no no, this.. this is nice. I should explore and experiment. -

Tip of 1/4" headphone cable plug broke off inside a locking Neutrik jack

penmarker replied to jpelg's topic in Do It Yourself

That's a beautiful clamp Fitz, do you have a link for that? -

I'm using a TKD4CP and the scratchiness had been there even before I used a volume pot, when I was using the pre out from my DAC. There is a small offset drift within the low 10's mV, but it goes from positive to negative. There's no distortion from the volume pot, the TKD is pretty smooth. I don't think any of my sources has any DC offset (Hugo V1, Matrix Mini-i). This doesn't happen with my other headphone amps. Since the opamp is in there as a servo, could changing the opamps help with the drifting offset? I'm half expecting it to be the opamp because I noticed the offset doesn't change with and without the opamp.

-

goldenreference low voltage power supply

penmarker replied to kevin gilmore's topic in Do It Yourself

Just to give my 2 cents because it had been my learning experience too while I was building various projects. I would discourage using boutique expensive parts on first few builds while you're still learning the basics of building/following directions before learning the basics of how the circuit and builds work. This is for all intents and purposes your own personal experimentation stage. A lot of things will go wrong. You will install diodes backwards, make solder bridges, miss out on the insulation pads on heatsink/chassis mounted transistors, and plenty others. It will be slow and learning will be an iterative process. In the end your chassis will be full of holes on top of apprentice marks and the boards will probably have lifted traces from constant solder-desoldering or wrong solder temperature. The outputs might not work the first time or even the third or fourth time. By then it will dawn on you that your boutique ultra low PPM resistors and silver plated wires and expensive tantalum caps had costed you more than buying a decent headphone amplifier. It will be discouraging things will start to look not worth it to proceed with the project. To use standard components are entirely fine. Triple check orientation before soldering and double check after. If you're building a 20V power supply, it's entirely fine to get a reading of 19.80V because you're not just measuring the PSU output but you also have your meter's accuracy levels that could affect the reading. Almost always, your second build will be better than your first build.