-

Posts

1,540 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Forums

Events

Everything posted by JoaMat

-

I’m out of town for a couple of days, but I see if I can post a picture of it when back home. Basically it just a piece of pcb, some three pin socket (green I think) and two wires.

-

Nice post with YouTube video clips above, James. One tool I’ve found very useful is desoldering gun. I use DEN-ON SC7000Z. The first one I bought nine years ago and it still working. Last year I bought a second one. DEN-ON isn’t cheap but it’s very reliable and it’s said to be possible to get spare parts if needed. There are different tips available and with the 1.5 mm I’ve desoldered the small 9 pin Teflon tube holder with ease. Another good thing with the DEN-ON is hot air blowing. With hot air blowing I remove smd parts. A few days ago when doing 0402 parts soldering exercise I tested to remove a few 0402 parts and that worked great. Then I put the parts back – good exercise...

-

Done some soldering exercise today. This small board contains 100 x 0402 10K resistors. Hand soldered with a Weller station, XNT-H tip and 0.3 mm solder wire. A few of the resistors are not flat to the board but I think they are acceptable soldered. Looking at your board, Kerry, there seems to be some really nasty things. Any chance for part numbers? I have to convince myself that the best way is to pay for a prepopulated board…

- 129 replies

-

- 10

-

-

-

-

-

Several years ago I changed all LEDs (only three per channel compared to 25 in the original DIY T2) in my modified T2 to LM336 2.5V, a voltage reference device in TO-92 case (I also changed resistor values to keep desired current of the CCS). Pros LED/BJT see Lefferts_LED_Used_as_Voltage_Reference_ED_Feb_15_1975.pdf. Pros LM336/BLT see Sources_101_P1.pdf and Sources_101_P2.pdf. Overall, at least in theory, I think LM336/BJT wins. My version of LM336 have operational temperature up to +70 degrees Celsius and I don’t think I exceed that.

-

Opened up my modified T2 from 2014, same circuit as James’ T2 but smaller board. All 140k resistors look as new. No decoloration at all but they are standing to save space. Maybe they are better cooled but it’s very crowded so I’m not sure about the cooling effect. A year ago I reduced the high voltages by 100V so batteries at 640V but before that it was “full” voltages. With three 140k resistors you get 1.7mA through lt1021-10 and I guess you can lower that to 1.2 – 1.3mA. 200k resistors gives 1.2mA and 300mW. Going with lt1021-7 as Kerry does you can reduce current further.

-

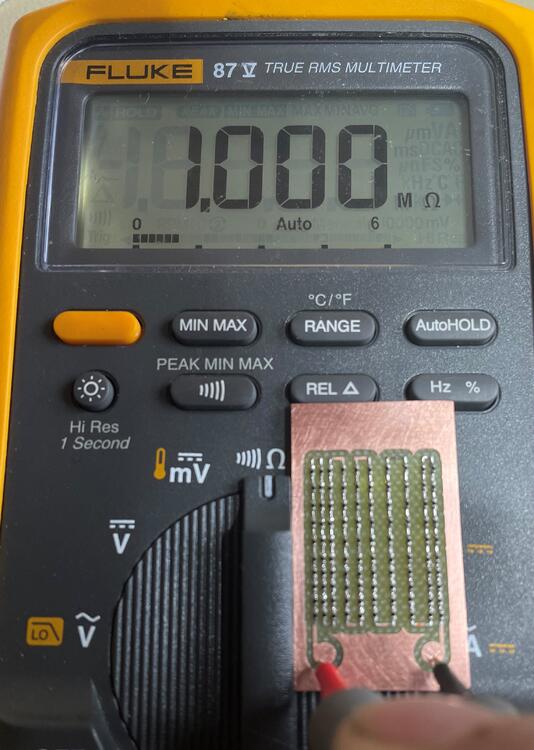

Great to hear about the new measurements which are in line with genuine 2SK216. When testing field effect transistors DY294 manual says “A short circuit should be formed between G and S pin. Otherwise the transistor can easily be damaged.” To make testing of k216/j79 a bit easier I’ve made a simple adapter for the DY294 tester.

-

Breakdown voltages that high for 2SK216 seem extraordinary. If the DY294 readings are correct I would say that the devices probably not are 2SK216.

-

A less contagious and unknown mutation? No need to. Informative posts are always appreciated.

-

Happy Birhtday, Kevin!

-

Great, this is the first time I see them boards, even if it’s just on photo. I want to add that one name is missing on the boards – Kevin Gilmore. Kevin added a few things like trimmers to set output current, test points to measure it, terminal blocks, part values, labels etc. etc.. During the work with the boards he taught me how to quickly make a mirrored (as far as possible) board from the first one. Thank you, Kevin. Welcome to Head-Case, Rich (sweetleaf)!

-

Thanks a lot for this project, Kevin and Kerry. At least the amp sections seem doable , even with my old eyes and clumsy hands. Is the board two layers or worse?

-

Many thanks Todd!

-

yep

-

This is how my first attempt to mill a pcb stencil turned out. The aluminum sheet comes from a Burgenfels beer can.

-

Thanks for the input. I use the software FlatCAM to convert CNC files from gerbers. Eventually I found the way to invert a gerber with just one push at one button. I’m very embarrassed I didn’t noticed the button, it has been in front of my nose all the time.

-

Is there any easy way to invert (“convert from positive to negative”) a gerber file. I want to invert the solder paste gerber file – then I think I can make a CNC file and mill PCB stencils. Or at least I can try…

-

I always do smd soldering with fin tip solder iron and after a long time of practicing I feel quite comfortable with that. I’ve tested with hot air station and with proper amount of solder paste on the pads and when using low air flow I managed to solder without components blowing away. And it’s a nice feeling seeing a component nicely aligning up on its pads. But I prefer the soldering iron technique. Me and solder paste don’t mix well. After a while the whole table is a mess and I even have solder paste on my nose. With some practice I’m sure everyone can do smd soldering, but it can be very frustrating initially.

-

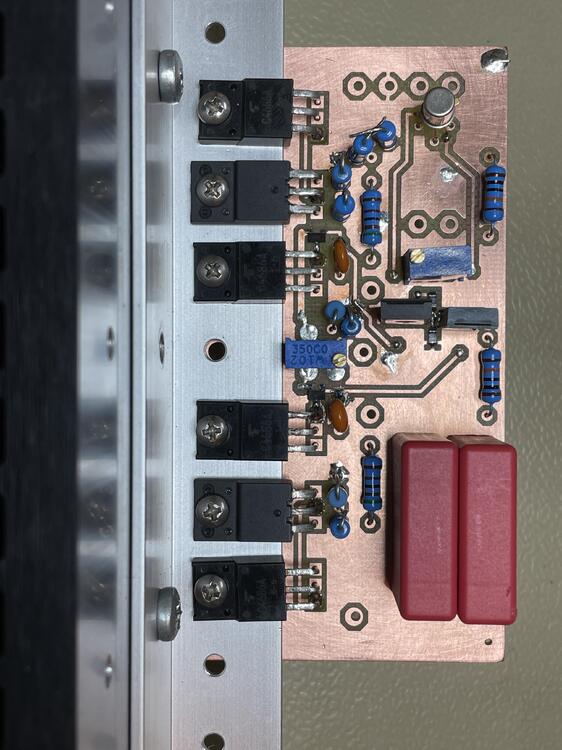

Here is a version with FJPF2145 in stead of 2SC4686 and 01N100D replacing 2SA1968. The file name is xxx_Mouser to indicate components are available at Mouser. Yesterday I completed the left side board and I’m listen to it this very minute. I’m very pleased with the outcome.

-

-

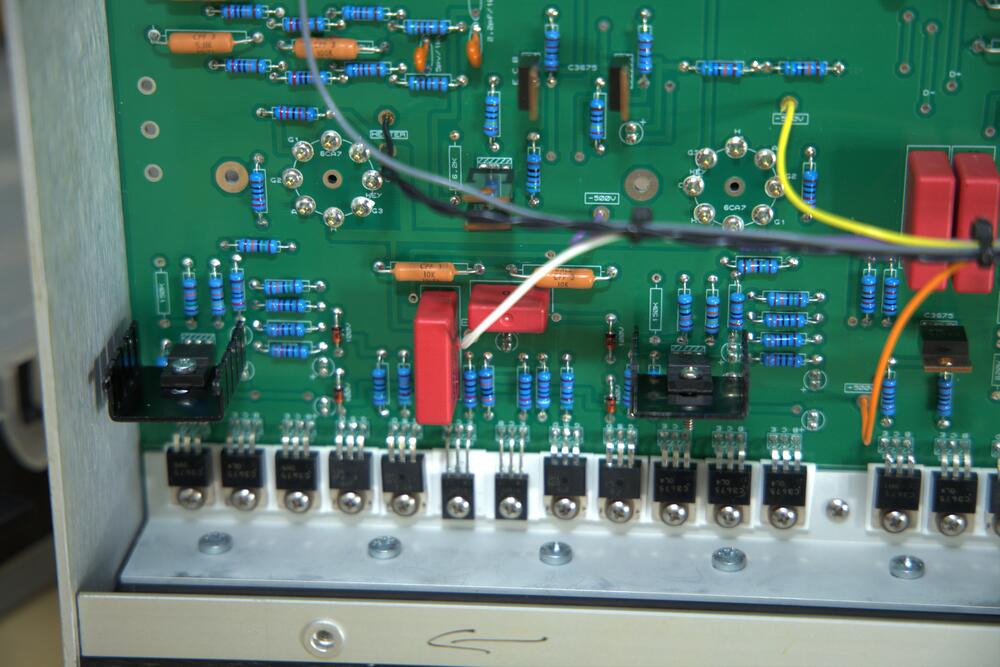

This was not meant to happen. Modifying the original DIY T2. But now it’s done. I couldn’t resist to change the output current sources. Replaced two 2SA1486 with single 2SA1968 and removed four 150K resistors. I put a small heat sink on the transistors. They will dissipate half a watt or so. 2SA1968 is a 900V device, but I’ve reduced high voltages to +/-400V so that should be fine. By the way the 2SC3675 is also a 900V device.

-

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

I might help you with a few. Ping me if interested. -

Megatron Electrostatic Headphone Amplifier

JoaMat replied to kevin gilmore's topic in Do It Yourself

Omit zeners along with the drop down resistor if you have the 300V supply. -

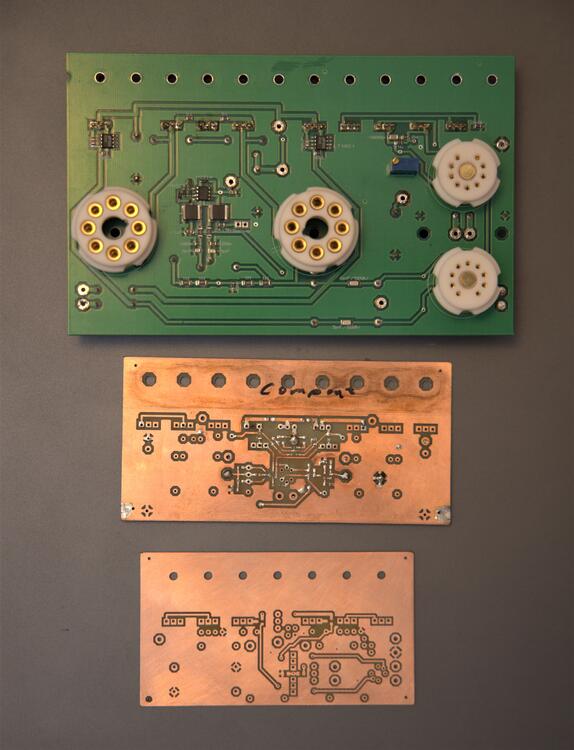

The first board is 120mm x 60mm / 4.72in 2.37in while this latest is 99mm x 56mm / 3.92in x 2.22in. Here they are together with a mini T2 for comparison.

-

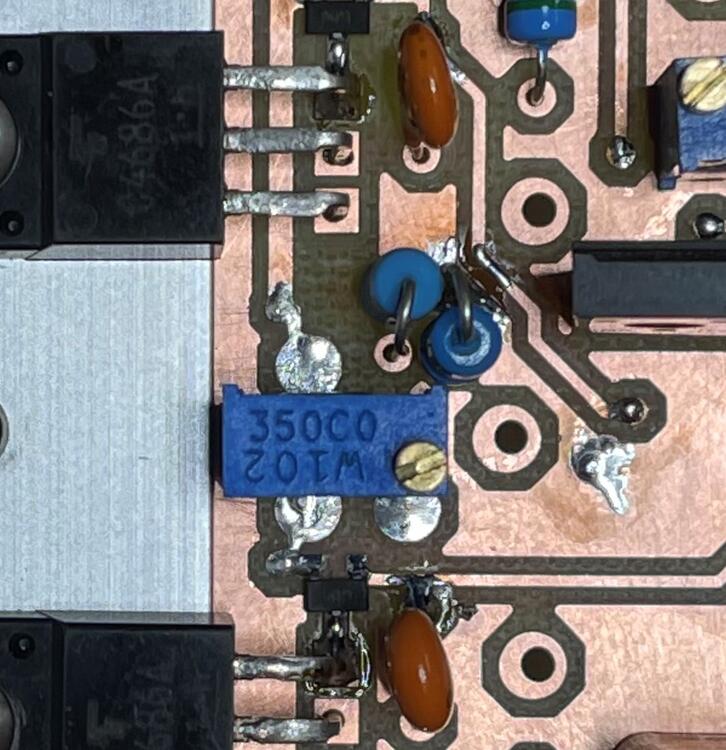

I’m working all week around. Today I milled left channel board similar to the right side done yesterday. Here it is. For some reason the holes of big pads aren’t centered. Grrrrr. Three round tanned pads close to offset trimmer are test points. Measure voltage cross 100R resistors R25 and R31 and you get an idea of current through output stages. I got 1.014V and 1.007V so approximately 10mA.

.thumb.jpg.84bc2c6d435c45bb9295fa0bd8524f1b.jpg)