-

Posts

8,566 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Events

Everything posted by Pars

-

OK, ran thru this on both boards: Initial check: The CCS's Use a lab supply at some ~15-20V, through a DMM at mA: put the (+) at the drain (middle leg) of the 10m90, and the (-) at the bottom of the CSS where R2(100) and R1(4k5) meets ...you should get ~2mA ....if you see much more, try replace the DN2540. Do the same at the other CSS: (+) to drain (middle leg) at the 10m90, and (-) at the bottom (pin 6 at the voltage reference) ...you should get ~1.3mA ...if not the 10m90 is probably damaged. Check the current limiting CSS you added (your drawing) the same way (Kevin suggested 50mA for this) For the first test, I was getting 1.6-1.7mA for both boards. 2nd test I was getting -1.3mA with the red lead on the 10m90 and black on lt1021 pin 6. I guess I will assume everything good so far...

-

Thanks James (and John). I was going to go thru the checks that soren laid out in the circlotron thread (and I copied his post earlier in this thread), and then power them up on a variac, unloaded. It might have been a 16K resistor that Kevin had mentioned, but I never bought any load resistors for doing this. Unfortunately my variac doesn't have an ammeter in it, but I'll just take it slow. I also don't have a dim bulb tester, but if needed, might build one.

-

About to (finally) begin testing the pair of GRHVs (and a Carbon) I built. Do I need any sort of load for testing the power supplies? I seem to recall seeing Kevin recommend a 16ohm x W load resistor.

-

No shit. Seems mighty Christian of him..."Nuke em all til they glow..."

-

and now for something completely different part 3

Pars replied to kevin gilmore's topic in Do It Yourself

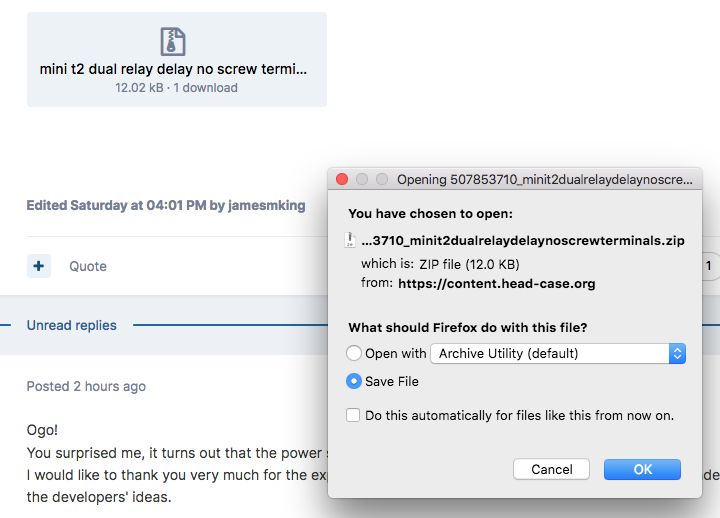

Here they are. THAT340-J109-K389-JFET.zip -

and now for something completely different part 3

Pars replied to kevin gilmore's topic in Do It Yourself

Kevin, The pinout of the bipolars is not compatible with the 2sj109/2sk389. I did boards for those and can supply the gerbers. They should also be in one of the dynalo, etc. group buys that Steve ran (sbeylo) some time ago. -

Happy Birthday Nate!!

-

Happy Birthday Craig! Hope you have a great one!

-

Happy Birthday Naaman!

-

Ouch Nate! I take it you had to ride into that?

-

Or head-fi. We like to keep the signal to noise ratio high here...

-

Happy Birthday Al! Hope you have a really good one!

-

^ Watched the first 2 episodes last night. Not bad, though the sister gets on my nerves. Will watch the rest.

-

Happy Birthday Colin!

-

Happy Birthday Steve! I hope you have a great one!

-

Not Stax T2, but when I used to have a Counterpoint SA5.1 preamp which used 6922s, the favorites that I used in it were some Amperex PQ white label 6922s. I would guess these are a) hard to find and b) expensive as fuck now. I also used the EH 6922 gold pins and liked them as well, but not as good as the Amperex.

-

Congrats Kerry! The amp looks great, and hopefully we'll be able to see some good reviews from CJ, though knowing that crowd, wading thru the tripe will be umm, fun. BTW, you mention "we" in talking about Eksonic...

-

-

and now for something completely different part 3

Pars replied to kevin gilmore's topic in Do It Yourself

You might try reading the thread before asking questions... -

So sorry on all fronts Jacob! RIP Dunhill.

-

Started watching Suspicion on AppleTV. I'm enjoying it so far. 4 London Brits are accused of kidnapping a diplomat's son in NYC. Uma Thurman is in it, though haven't seen much of her yet. https://tv.apple.com/us/show/suspicion/umc.cmc.64yj71dmrdihhmo96h0lgjmw5?ctx_brand=tvs.sbd.4000&ign-itscg=MC_20000&ign-itsct=atvp_brand_omd&mttn3pid=Google AdWords&mttnagencyid=a5e&mttncc=US&mttnsiteid=143238&mttnsubad=OUS2019930_1-579300337890-c&mttnsubkw=134890699151__jKEV8OEz_&mttnsubplmnt=

-

Been looking for something like these, but can never seem to find them on Mouser or Digikey. Something like the splice terminals used just below the transformer in this picture:

-

Funny Nate as I did the same thing and watched the first 2-3 episodes. I didn't mind Cruise (and haven't read the books), but I think this take is probably better and sounds like it adheres to the book(s) aesthetic better. Mindless entertainment is a perfect description as well