Leaderboard

Popular Content

Showing content with the highest reputation on 04/08/2018 in Posts

-

10 points

-

Milo and I got the speaker boxes mostly complete today. Made some round holes and some rectangular panels. Tweeter holes are in the Cherry baffles only, as they're not deep enough to need holes in the MDF panel too. Woofer holes and port tube holes in back. Cherry baffles got milled and drilled as well. And the first coat of Arm-R-Seal. The fluting is strictly aesthetics.7 points

-

7 points

-

4 points

-

yes the amp is balanced. whether there is a opamp unbal to bal converter like the liquid carbon or lcx, is unknown. But there is no reason why the front end cannot be a differential amplifier and then its balanced. of course that depends on your definition of balanced, its not the same kind of balanced as a super symmetry dynalo. its a unbalanced/balanced to balanced converter and then 4 x cfa output amplifiers. Same as liquid gold, liquid carbon, lcx. I see the confusion from my post, the single ended output is going to be limited to something like 18vpp (30 volts - VGS(x2)-2) whereas the cth would be about 26v This amp is definitely to compete with the lyr3. whether they knew that the lyr3 was coming or not. Both amps have serious limitations and issues. also that picture is the cavalli version the monoprice version will probably be different just like the differences in the original cth and the production version2 points

-

2 points

-

2 points

-

2 points

-

1 point

-

1 point

-

Conditions were pretty epic today. Rained most of yesterday. Plus all am until 9 then the sun came out. I went out at 1 pm, dirt was perfect and mid 50s plus a very strong wind meant that after warm up I hit the slow technical stuff for 3 hours and hardly went through my water! Late October through April is my favorite time of the year in the Sierras. BHSE always delivers when I get home, thanks Spritzer. Plan is the same for tomorrow.1 point

-

If you buy the duals in the linear devices, you can just go with what you get. The 2 devices in package are matched pretty well, and Kevin said that CCS will take care of the N-P differences you have. The ones I bought from trendsetter (LSK489/LSJ689) weren't too bad.1 point

-

it may have been cute when schiit came out with its original batch of cheap shit. all sorts of compromises necessary to produce something for $149 But now we have schiit competing with massdrop competing with monoprice, producing seriously compromised product for prices approaching $700. All sorts of issues including virtually no class A output power, split rail power supplies, low component life due to some really high chassis temperatures, noisy external switching power supplies and flyback switchers internally. Throw away product for sure. When you can buy real products from real companies for $500 or less.1 point

-

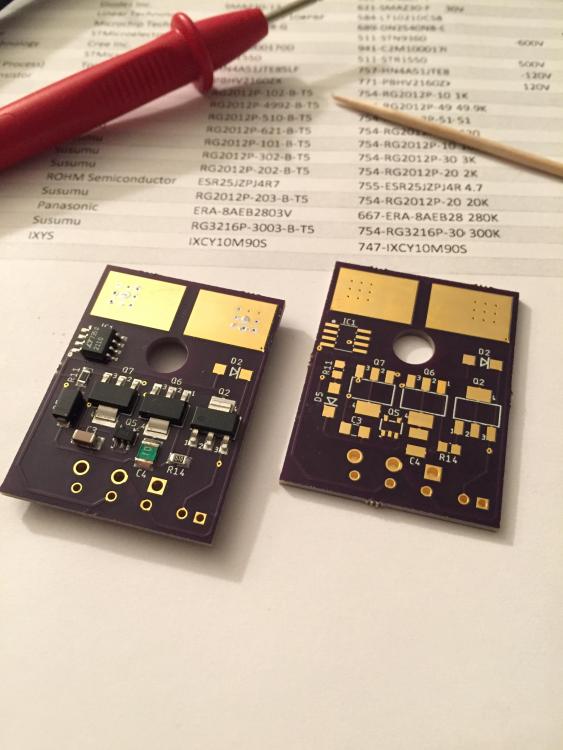

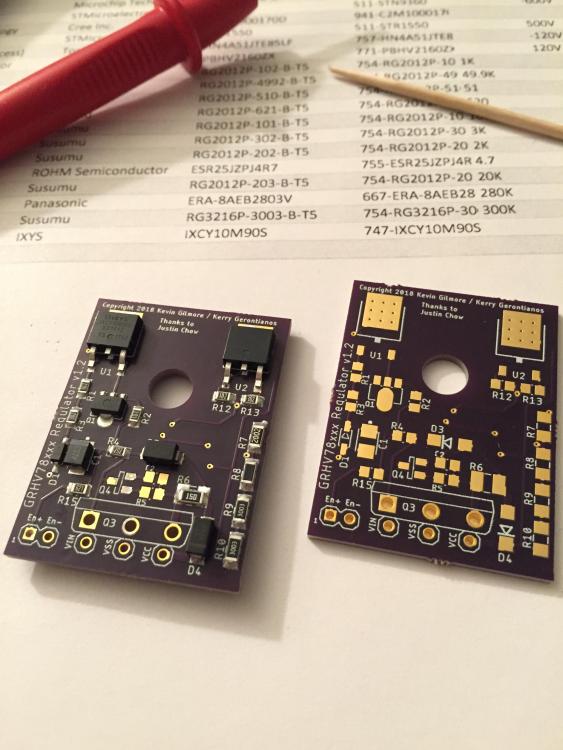

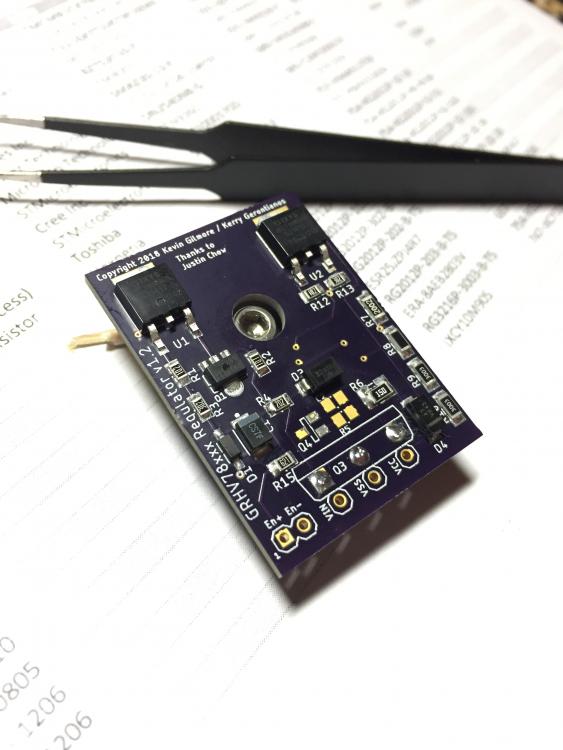

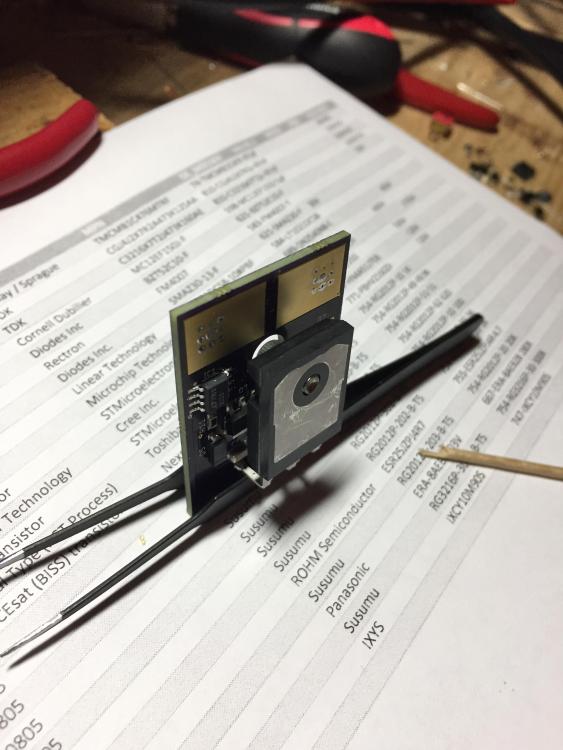

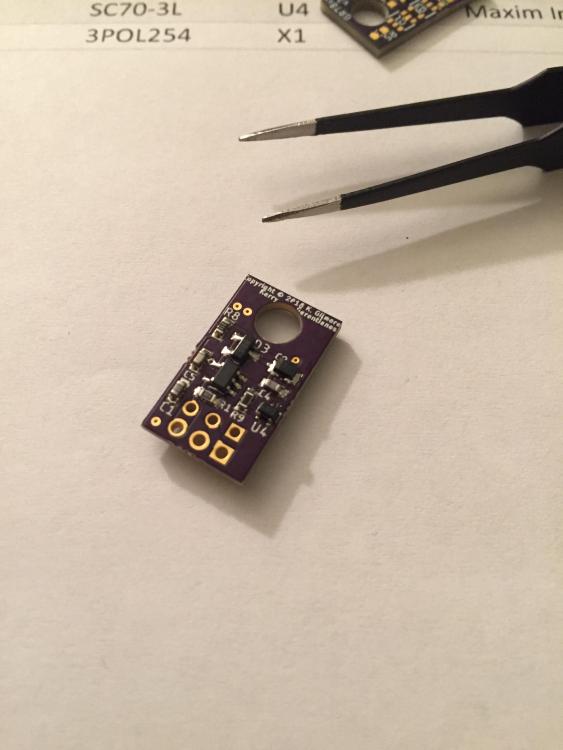

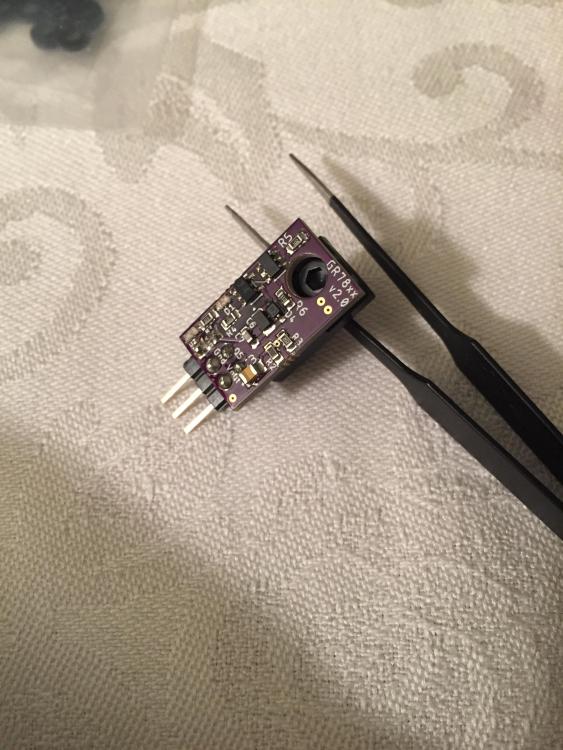

That's really a disguised silver dollar there, isn't it Kerry Very cool! Now, tell me what these will do?1 point

-

Can you get some grain oriented steel and wrap it around the transformer. That's what I did with my 2 channel build in one box. It reduced the hum to almost nothing1 point

-

1 point

-

I'm in the near final stage of my GeorgeP cased T2 and talked to a EE hardware manager on my team at work about heat sinking. The discussion was useful so thought others here might like to hear what he said. Turns out he has a lot of experience with heat management, since dealing with every mW is his biggest issue on the platform and they've struggled with it for years. What they found is that the the only factor with heat sinking is air gaps, since air is an insulator. Torquing is only specified as a poor mans way from the manufacturer of trying to ensure there's no gaps. Beyond the normal smoothness you find on a heat sink that also makes no difference - it all comes down to having a thin layer of compound (ideally it would be zero but obviously we have to suffer with minimal compound) with no air gaps. It's so important for them that they x-ray every one, and they use no hardware to clamp the parts down - just normal soldering. The key is good technique in applying the compound and placing the part. If you do that right torque, lapping or anything else doesn't help. I explained my project and showed him pictures. On hardware he didn't like the idea of using steel screws with the HV silicon - he recommended going with the Peek screws for arc safety and again - using good compound application technique with the screw there just to hold everything together. Further on having all that aluminum and parts screwed together (IC's, brackets, sinks) he was concerned with creep. Ideally you attach to a 'hard' surface, meaning one without creep. A thin PC board is fairly hard, but aluminum isn't - he described it as 'mushy'. You can screw to it but over time the aluminum under the screw points will "flow" away from the pressure point. So, what they do (because everybody has to suffer with aluminum sinks) is to use a wide steel washer under the clamping bolt. This works well to ensure the bracket/sink stays together with thermal cycling. Otherwise he suggested a yearly physical inspection of IC to bracket and bracket to chassis to ensure a continuing tight fit. So, he recommends PEEK screws, don't over torque (or worry about torque at all), but be fanatical about compound application, such as using a non silicon based compound like AOS 52022KH for long term stability if you like. For attaching sinks and such he recommends using a wide steel washer (not a 'lock' washer) to spread out the pressure point. FYI -1 point