-

Posts

1,539 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Forums

Events

Everything posted by JoaMat

-

One could say that the legs of BJT is shifted one step to the right. So I just bent the legs accordingly and put a pin header in the left hole and then mount the transistor with desired torque . As I do it the pin header is hold in place by the crossed leg. Solder and it’s done. Few pictures below. Hope they show how I did it. I've modified one T2 and one Blue Hawaii this way. And it works fine.

-

-

Very nice indeed.

-

Indeed a most elegant amplifier. Impressive chassis work - like a Maserati.

-

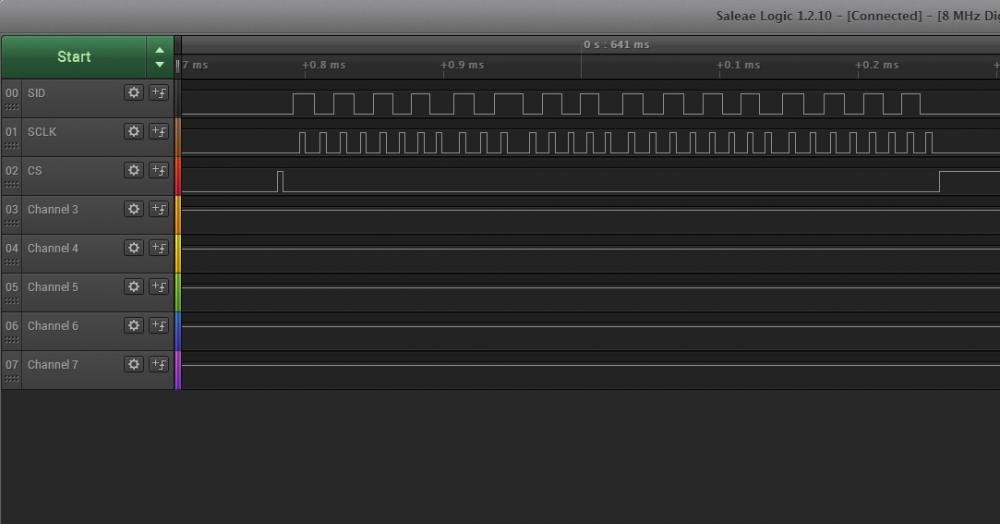

Managed to squeeze the code in ATtiny85. I do think it will be able to control the balanced digital attenuator... ...maybe.

-

-

Wanted! Anyone willing to sell me a balanced digital attenuator board? or two?

-

Wow, absolutely amazing!

-

I consider my T2 to be absolutely silent. I can't hear any noise, might be because my old ears though.

-

May I help? Q1/Q3/Q13 - MMBTA56 Q2/Q4/Q14 - MMBTA06

-

Superb. And it has your signature… one could see from far distance that it’s a John William McClean coming, something like Mercedes S Class.

-

Kerry, how long time does your machine need to mill the amplifier top plate?

-

Nice!! Especially the form of top plate at the screws against the heat sinks.

-

Could it be the LT1021 that is the problem? It's supposed to be 10 volts as long as the regulated voltage is some 20V or higher.

-

I want to add that I use the Raspberry with piCorePlayer and a iPad with iPeng and Squeezepad apps. I’m very happy with the piCorePlayer and the iPad apps - Internet radio (I listen to BBC3 HD every day) Tidal, ripped things on hard disk, Met Opera, Berliner Philarmoniker. Pretty magic, isn’t it? Everything works terrific until batteries fade.

-

-

I’ve had a great time the last couple of weeks building the mini Dynalo designed by Kerry. Here is the Dynalo with a finished (almost) board. Side panels from Modushop, internal height 40 mm. Front and rear panel are copper clad boards milled myself and the top cover is an aluminum net for better ventilation. Now, this amplifier turned to be a very nice one, so I started to modify it for my own personal preferences. I want a small portable amplifier to be used in my garden under a cheery tree - resulting in this. Switching power supplies, all connectors at the rear panel and some other stuff not needed removed to give room for Raspberry Pi 3 with a HiFiBerry DAC+ Pro on top. Changed front panel (easily done with a mill and copper clad board) and rear panel has two holes for connectors for the batteries and a wlan antenna. Today I got a heat sink for the output transistors. Below is a picture showing them, they are just resting on some soft pad – have to figure out the best way to get them fastened. I don’t think the sinks are needed but they are very much preferable. Many thanks to Kerry for an excellent work.

-

Bought from Elfa in Sweden. Sorry, but I can’t find them on Elfa now. I’m sure you would find some similar if looking around.

-

-

Me to find that blue plastic water can very interesting. What worries me most is why Vikings like Soren and me are more interested in plastic head phone stands than the head phones???????????????

-

-

-

-

Output transistor on bottom side thermal connected to case via Bergquist soft pad? (Brainstorm - to many drinks last night)