-

Posts

13,716 -

Joined

-

Last visited

-

Days Won

39

Content Type

Profiles

Forums

Events

Everything posted by luvdunhill

-

How much do you loose due to the blade to dust?

-

I used that one on a turntable tachometer and it worked quite nicely. Are you just looking for a binary “yes” or “no”? In which case you might also want to use a comparator. I can post the schematic and board files for what I did, which also supports an optical sensor.

-

How about AH3377?

-

She needs a bit of a bath, as got caught in a bit of a downpour and then took a bit of a tree with her on the way into the garage, but…

-

The Lynx is super cool. I am curious how it stands up to boat wakes.

-

Awesome, those will be a ton of fun!

-

Thinking hard about a Hobie Getaway. Been too slow on the used ones near me and the local dealers don’t have any tricks to deal with Hobie’s horrible supply chain. Signed up for sailing lessons starting Th - excited about that!

-

Obviously custom-title worthy.

- 2,110 replies

-

- 1

-

-

- Golf Mafia

- M Sport

-

(and 1 more)

Tagged with:

-

I tried the heat gun in the picture but the issue was the bubbles were inside the fill and the heat gun made the epoxy look scorched. Oh well, only one fill in the end had bubbles. When I tried to put another layer on top, it didn’t bind well. And when I scraped it, the entire second coat came off… This was the TopOil which is a lot thinner than the Polyx. It’s a very odd substance, it is very hydrophobic - very hard to get off your hands with water. I also in testing found the directions on the can didn’t work as well. I ended up applying the first coat pretty thick with a synthetic pad. In my tests that worked better than the usual thin rubbed on coat. I haven’t been back to check on it but hopefully will get to it later this week.

-

Started with this then made it look like this then decided to play with chemicals then made it look like this via a probably Doug approved implement called a card scraper, then put the first coat on! probably will do another coat, might sand between coats? I am not sure what is recommended with this Osmo stuff… But; it looks ok! - I found out that if you get bubbles in the epoxy it’s doesn’t quite work to just put another layer on top. Also the really shallow flaws didn’t hold the epoxy well. I kinda wanted a contrasting jet black color in the various cracks and crannies and it looks pretty decent! There were some knotholes that went all the way through the plank and those took the epoxy really well.

-

Do both options have the same experience when used via Roon? Specifically, metadata, album art, etc.?

-

Depends how much he dicks around.

-

Still smiling about this one

-

Awesome! I tried a “remote” thermistor (Murata NCP18XH103) and ended up just using a LM234 and some resistors.

-

goldenreference high voltage power supply (GRHV)

luvdunhill replied to Pars's topic in Do It Yourself

I ended up using the LT1021 - in haven’t tested that circuit yet, but it’s soldered in waiting to get some juice. -

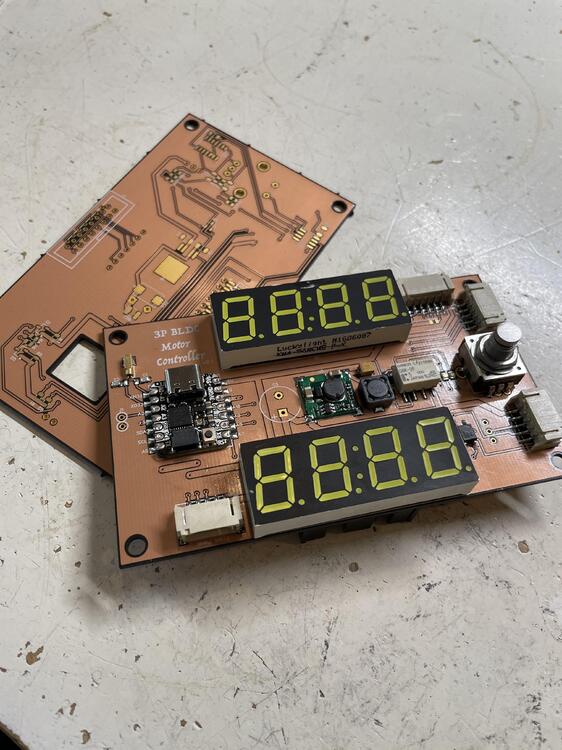

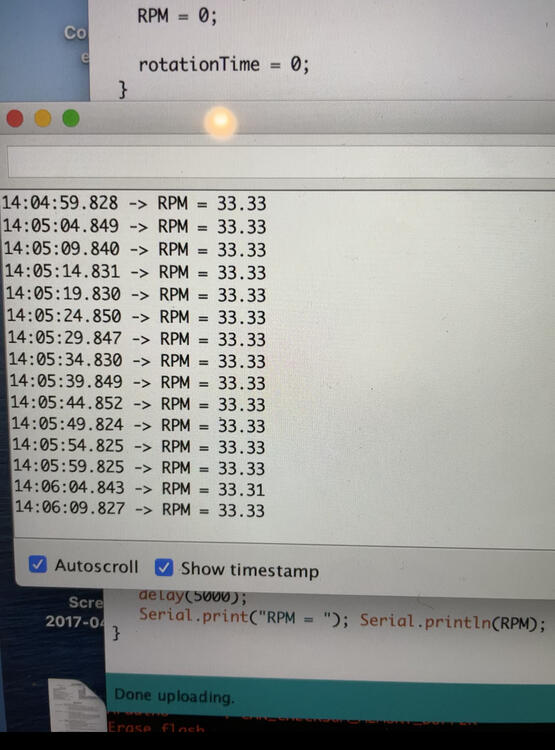

Actually, no but good question! I have three of these identical looking PSUs now - keeping the simple aesthetic. The PCB could be mounted that way though, but in my “case” it won’t. I plan on logging hours the TT is on (to estimate stylus wear) and how accurate the speed control is. I will retrieve that data off the USB port if needed. Here it is in action. The top display is the actual platter speed. Next to write the auto adjusting code. https://imgur.com/gallery/UXOn6R9

-

Woo, looks like the CPU board is working! Currently set at 20.29 Hz for 33.33rpm output. Got the front panel also working and now just need to solve the issue of the reflective IR Sensor (or go back to a magnet) - which I think might take a shroud to try and reduce stray light. The second display will then read out the actual platter speed as measured by the tach. Then I can adjust the speed in a feedback loop (PID). Still smells like a busted cap though

-

Soo.. what you are telling me is the white stripe on that black square thing is positive, not negative? Ok, that released some smoke and fire…

-

I dunno, is it okay with Larry if we use that? We haven’t asked permission after all.

-

This has been a handy device for me - even has pads to control it from a micro controller: https://www.amazon.com/DROK-Adjustable-Electronic-Discharge-Resistance/dp/B07KQS74C6/ref=mp_s_a_1_16?dchild=1&keywords=programmable+battery+load+tester&qid=1619718835&sr=8-16

-

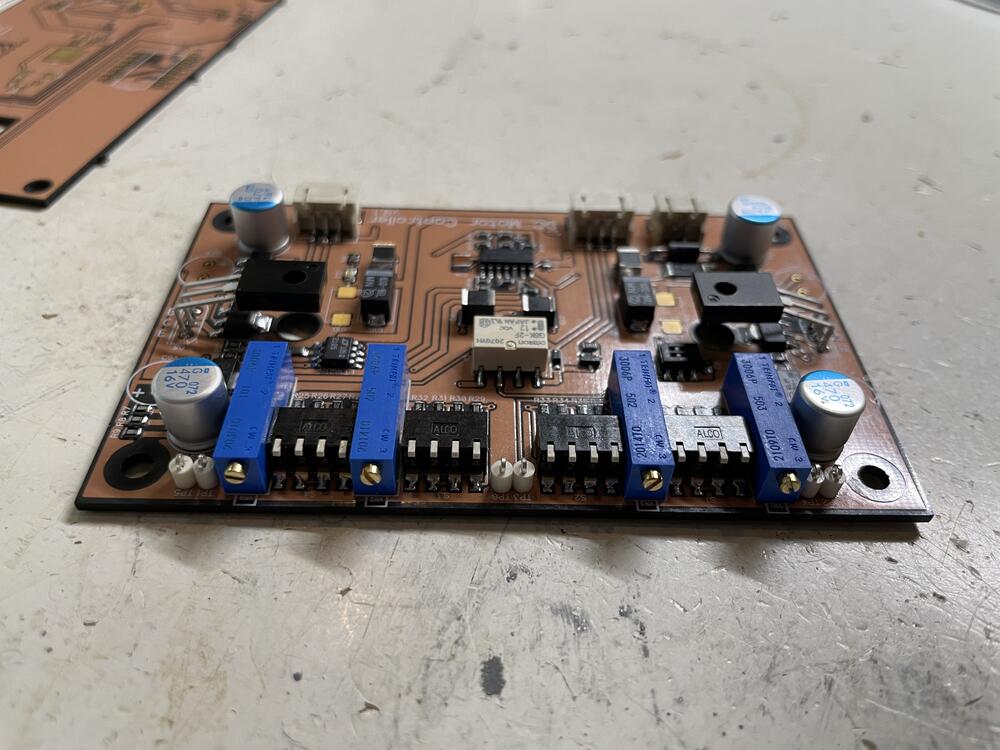

I have been continuing to play with turntable motors. I have two projects, one a controller with platter speed feedback for 3-phase AC motor and another controller for DC motors, which is an ultra-compact version of the one in swt61’s turntable to drive the Maxon motor. Here are some photos, just got things soldered up and have a whole lot of very tedious testing and software writing to do in addition to the SAMD microcontroller, that cutout is org castellated pads will also fit the new Raspberry Pi 2040 chip, which I am hoping to play with a bit. I hope they work!

-

Ok, who logged back into Huddler-Fi? Come clean.

-

Nice work! So I see you removed the door and window trim and then somehow fancied it up?

-

I got the code working to measure the platter speed! The sensor is still wonky - maybe I need to build a shroud around it.. Maybe I just built a ghost sensor! That would explain a lot... maybe this is the newest fad in audio accessories

-

The optical based sensor seems much more fiddly compared to the magnet. It’s influenced by ambient light (for example record needs to be on the platter) and I am using a small craft mirror on the platter but not sure if just a white dot would work better? The part is VNCT2020. IMG_2400.MOV