-

Posts

13,716 -

Joined

-

Last visited

-

Days Won

39

Content Type

Profiles

Forums

Events

Everything posted by luvdunhill

-

Has anyone listened to a system with the Acoustic Elegance dipole woofers? I was looking for a high Qts OB driver and ran across them.

-

So, basically vegan ambrosia maple? I dunno that seems a bit too far.

-

-

They are called board-to-board connectors.

-

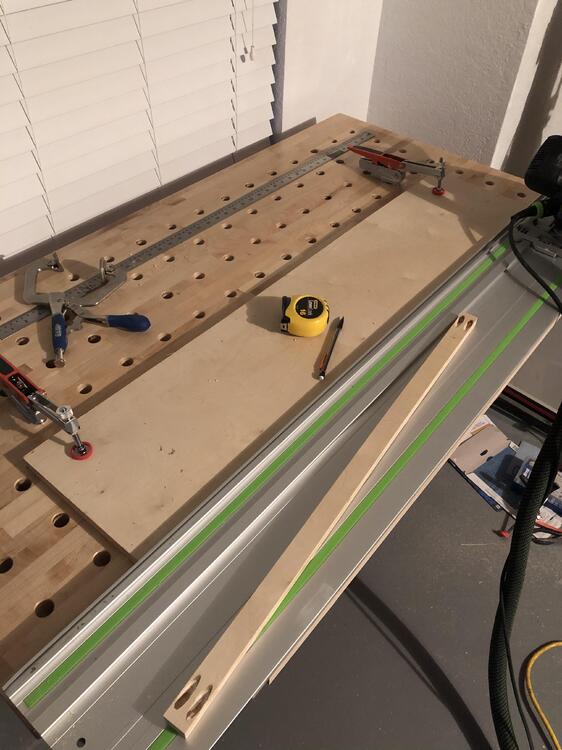

All worked well. Sliced up the ply into 1” strips and then used the pocket jig to make a frame. I think 1” is too narrow so will probably do 1-1/2”.

-

Tomorrow I am going to cut up some remaining Baltic Birch ply to make some frames for speaker grills. That will involve a bit of clamping and screwing here and there. So, stay tuned!

-

It seems to work great! I am not a huge fan of using a long screw driver to attach the top - having pre-drilled pilot holes would be nice. Other than that; it’s bolted to the ground and super stable. I sanded and put a coat of finish on my phono preamp faces just now!

-

Yeah, 54" model. I will have a few projects on it this week and will report back!

-

-

The Never Ending Search for a Music Server

luvdunhill replied to n_maher's topic in Home Source Components

The one swt61 has has digital out. -

-

Pretty nifty!

-

What do you use to download and play MP3s on an iPhone in 2020

luvdunhill replied to Voltron's topic in Portable Audio

Isn’t a dongle the answer? Ya know, use the camera kit connector with the USB-C to Thunderbolt connector to Lightening Cable? -

So the threaded rod goes all the way through the legs? I don’t get where you are putting your nuts?

-

Bottlehead electrostatic headphone amp

luvdunhill replied to frankg's topic in Headphone Amplification

Glad someone figured out tube pins could be used for decent Stax sockets -

I am considering what would be a 5.2.2 Dolby Atmos System which would leverage some existing ambient speakers for the “overhead mids” with a switch in the wall to toggle them. Here is the guide: https://www.dolby.com/siteassets/technologies/dolby-atmos/atmos-installation-guidelines-121318_r3.1.pdf

-

I am really excited about the Marantz NR1711! https://www.us.marantz.com/en-us/shop/avreceivers/nr1711 Pretty featured packed. Will be my third slim-line, following various updates they have made.

-

Cool, thanks for sharing!

-

I used tap magic (because I had it on hand, and it smells nice). Maybe there are better choices? I also tried a spade bit (not pictured) but it wasn’t nearly as good of a cut as the others.

-

Did the same thing. But wasn’t smart enough to think of the dealership, so called the Fire Department. Yeah, took some explaining.

-

Oh also, no difference in quality versus the Klein and EZ-ARC carbide circle hole bits. In fact, the EZ-ARC might be slightly better. Save money, go cheaper

-

I was able to get mostly round holes lined up. These two holes will have bolts and room in the larger hole to accommodate a 15/16” deep socket. I tested them out this weekend and they hold the heavy tandem kayak well. I am going to build a second level with another pair of hooks. Pretty pleased so far. Now just need to avoid mistakes for the smaller holes Also, this alloy seems to be considerably harder than what I have used in the past. This is 6063. All my previous circle hole cutting has been 6061. With this, is the carbide saw is the tool of choice. The wood-working bit was a bit... “scary” (though it did produce a cleaner hole) experiment on scrap: No luck with a Punch.... or I am just not strong enough. This is 1/8” wall.

-

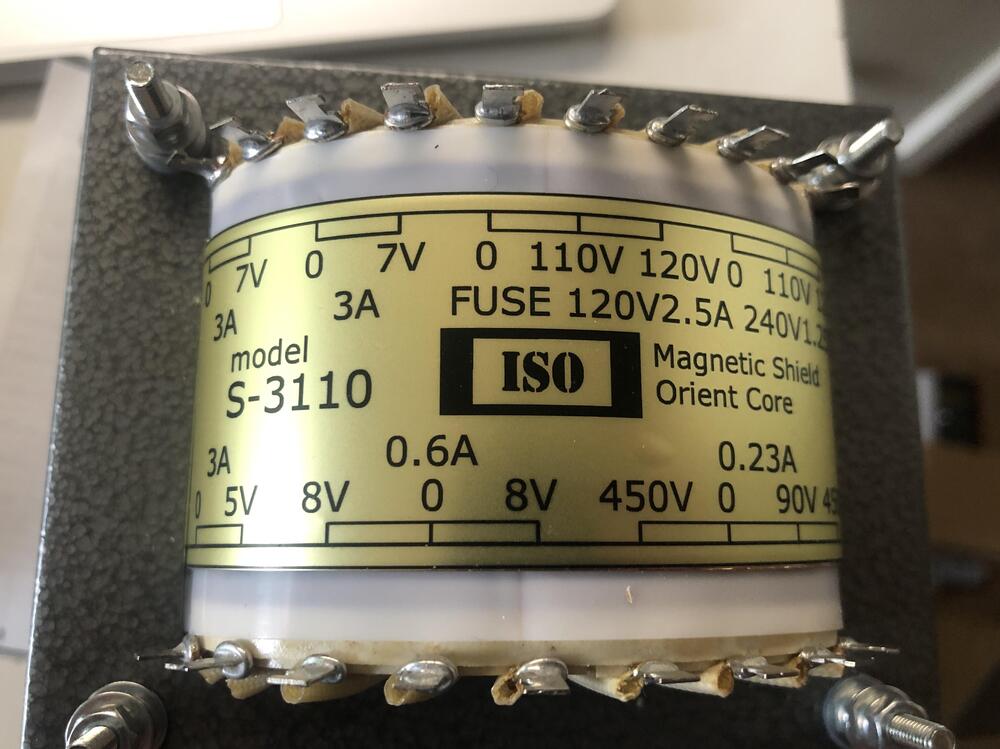

In other related news... look what showed up from Japan: Its friends are still stranded in Japan, waiting on EMS service to resume...

-

Searching for silent 220-110 step down transformers

luvdunhill replied to Sherwood's topic in Off Topic

I would perhaps see what Torus Audio can do here. Regardless, find someone that uses the Plitron LO-NO transformers - I imagine there is a step-down version.