-

Posts

27,331 -

Joined

-

Last visited

-

Days Won

285

Content Type

Profiles

Forums

Events

Everything posted by n_maher

-

-

-

I have to say that I'm thoroughly enjoying my 2019 16" Macbook Pro. The keyboard alone is a tremendous upgrade vs. the 2018 Air (which in itself is a great device). I'm going to end up using AppleCare+ to refurb the Air and then pass it on as for travel I can pretty much get by with the 11" iPad these days.

-

Happy birthday, Ian!

-

Funny guy, funny guy… I’ll fix the post but no, riding a measly 100 miles that day. Hope to trip the 3,000 mile barrier tonight.

-

Bah, this is HC, one thread is as good as another. My (state run) liquor store has the Flor 18 in stock for $39.99/750mL or maybe I should spring for something more in keeping with this place.

-

At the equivalent of ~$30/lb (unless you buy 2lb, then it's $25/lb) that stuff is out of my league.

-

Thanks Antonio and I fixed the link in the first post. Copy/paste user error fail, SNAFU.

-

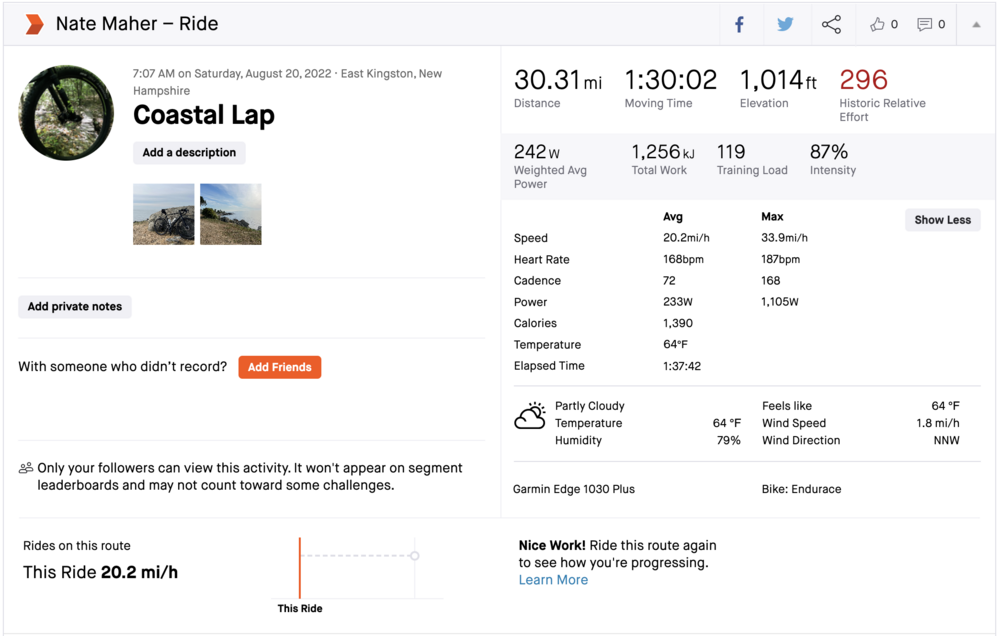

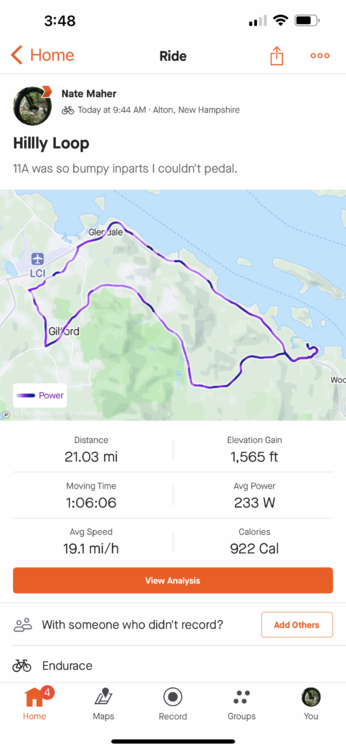

Once again this year I'm prepping to ride a century in support of the Kelly Brush Foundation. Between indoor Zwifting, the MTBs, and the upgraded Canyon this spring I'm creeping up on 3,000 miles in preparation this year and will surpass that mark before the event. Once again this year it'll be an in-person ride up in VT, with friends mostly coming from near-by so we should have a strong crew of 8 with some riding the 50 and most doing the full 100 miles. For me this is the 11th century that I've done in support of either Northeast Passage or Kelly Brush and I'm looking forward to enjoying it and hoping that our trend of good weather continues. So the mission remains the same, I'm trying to raise a bunch of money again this year with a goal of $2,000. As usual, all of the donations are tax deductible and maybe some legislation will get passed this year to make that more meaningful but really, I'm hoping the motivation isn't just to get a write off. So for those that are interested, here's the link to my personal fund raising page - Nate's Fundraising Page. Any donation large or small is very much appreciated. A bit about KBF - they are a non-profit organization dedicated to assisting individuals with spinal cord injuries in finding ways to get out and enjoy an active lifestyle. For me, this is a cause close to my heart. I love the outdoors and the freedom to explore it in a variety of ways and have worked with organizations like the KBF for the last twenty years to help others do the same. Last year's group at the starting line. EDIT - Link fixed...

-

Recipe?

-

^^^ Hell yes, Al, I've been meaning to try to make something similar for years (basically a gyro) and just never seem to get there. Me: 11lb brisket went on at 7am. Expect the flat to be ready for dinner, burnt ends to be ready for all things leftovers by later this evening. I'm trying a somewhat modified rub based on recent "discoveries" by YouTubers that Texas has been lying saying that it only uses salt and pepper on brisket. Turns out (allegedly) most use some version of Lawry's Seasoned Salt so I added a bit of that this time to see if I notice any real difference.

-

So much this. Good dog, Isabella.

-

Happy Birthday, Tood! Here's to hoping you had a great day.

-

-

Generally speaking, no. Can't say why, since I put sugar in my coffee but even out of the French press (as close to pour over as I get) I prefer earthier beans. It's not to say that I can't enjoy the occasional fruity/sweet described coffee but they tend to be much more hit-or-miss and not often worth risking a pound of beans on.

-

-

Want to build a balanced dac. dont know where to start

n_maher replied to BadgerMcBadger's topic in Do It Yourself

This might help. -

^^ Looking forward to impressions, I still toy with the idea of picking a flat top up. Haven't gotten there yet.

-

^^ I've had very good luck and been very happy with the Yamaha in my HT rig for the last 5ish years (geez, has it really been that long???) but might suggest sticking with something from the Aventage portion of the lineup as they are supposed to be far more robustly built. That is what i did when I bought mine. Maybe this Shelly - https://usa.yamaha.com/products/audio_visual/av_receivers_amps/rx-a2a/index.html - or see if you can find a b-stock or lightly used prior year model online? I'll do some hunting on that front.

-

I just finally got around to starting this, it's quite good and definitely entertaining.

-

Unfortunately, it's unlikely to be economically repairable or possible to remap another channel to the FL channel. I've looked at a few similar things and in my experience it's very difficult to find the problem unless there's literally a smoking gun (circuit board) and even then, it's just so unlikely that there are parts that are replaceable that are also serviceable.

-

Condolences to you and your family, Chris.

-

Happy Birthday!