Leaderboard

Popular Content

Showing content with the highest reputation on 12/18/2021 in all areas

-

Cases and heatsinks are a problem for DIY builds. Front panels of thick alloy need machining and tapping as do heatsinks. These items are hard to get machined or the sizes the builder wants are not available. I devised a way of making cases, which eliminated these problems and made for easier case design, lower costs and quicker builds. Cases Made from sheet aluminium alloy of preferably 3mm so only single sheet of material needed. I get the parts laser cut by a company which will also supply the material. The case parts need holes to be countersunk where necessary and are then taken for surface finishing, (bead blasting and anodising in my case). I then take the front panels to be screen printed with the graphics I provide. The assembly is with corner posts and angle brackets cut and drilled, and bolted together. I only drill and tap corner posts to attach base and top panels. The case is basically a box with a front panel on to cover the front of the box. Heatsinks https://uk.farnell.com/amec-thermasol/fch505010t/heat-sink-50mmx50mmx10-25mm-ceramic/dp/2499023 Edit; a link to these was omitted, http://www.amecuk.co.uk/ Element14 has them in many countries. https://www.newark.com/c/cooling-thermal-management/heat-sinks?brand=amec-thermasol I discovered porous ceramic heatsinks and realised that these small, light, self-adhesive items would solve problems. I bought a few and tested to see if they did what was claimed. A single 50mm square of 10mm thick could dissipate 5-10W stuck on sheet aluminium. To make heatsinks you only have to bolt the semiconductors directly to the 3mm plates and place the ceramic heatsinks as needed. They are not expensive, and with a range of sizes you can arrange heatsinks of different shapes. I was concerned that they might unstick but the opposite has been true, they are hard to remove. They are not pretty so I contain them inside the case and organise slots above and below to act as a chimney to allow convection. This works well and they do not run hot. The porous ceramic devices are very effective. I have found that this method is much easier to procure and build. The amplifiers built this way can be smaller and lighter.6 points

-

5 points

-

Is it possible that nobody made any Mattnog in 2021? Seems like a tragedy. The Mason jar sidecar shown above in my 2020 nog pics was consumed last night with some freshly whipped cream and it was delicious. Reposted here for the sake of the historical record. We'll need to do better in 2022... In looking for pics of ironbut Steve, I happened upon this one of Matt and me in SF. By very random coincidence, I'm wearing the same t-shirt today. 😏4 points

-

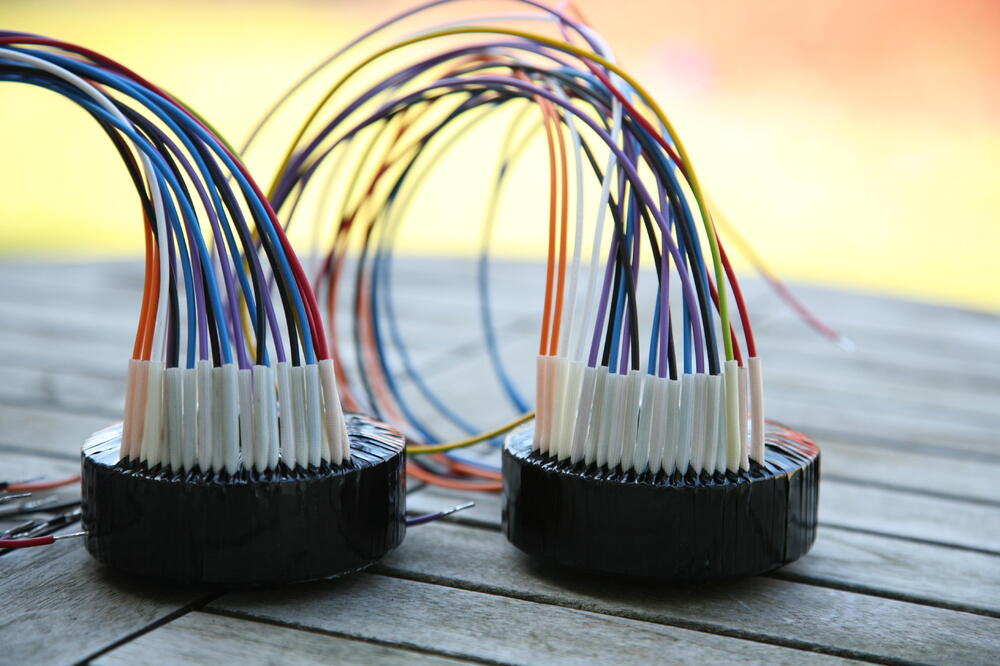

After several years layoff I have built a KGSShv Carbon which uses boards I had in and 4 Cree sicfets from several years back (luckily). The power supply is KGSShv v8 and the amps Carbon v6. It has been one of the easiest builds because of a different way of making the cases which I have described in Making diy cases, https://www.head-case.org/forums/topic/18892-making-diy-cases/ It is set for 400v supplies and 17mA output stage currents. It does not get particularly hot in a 20o C room, the heatsinks run a max of 40o at the centre. The power supply pass transistors are bolted to the bottom of the case and the case runs pleasantly warm to the touch. The size is 335 W x 314 D x 155 H inc feet. Weight 8.5Kg. (13in x 12.4in x 6.1in, 18.8lb.)3 points

-

1 point

-

You guys are really missing out. One of the better remote videos I have seen.1 point

-

Same here. I just assumed it was straight porn anyway, so no big loss for me.1 point

-

1 point

-

A friend of mine texted me this evening "So is your show ever going to be back on the air?" I said "Still don't have a new lappy and Macintops are four grand easy. I'm not famous enough for a Patreon or a GuFundMe." He said "You should set one up anyway."1 point

-

That looks nice. Sounds like I should look into FlatCAM. How many different bit sizes did you need to use to make the board? If you don't mind me asking what are the sizes and types of bits that you used?1 point

-

Maybe get these instead for work 😁 Cometeer - Earth’s First Hyper Fresh Coffee1 point

-

Finally I got round to getting some time in the workshop: the DC protection circuit is up and running! I decided to do a prototype on my CNC. Converted Gerber files to Gcode with a software called FlatCAM - free, full of features and easy to use! Quite pleased with the result... Assembled and tested: - power on delay ist about 2.5 seconds. I might want to increase that a bit. - The voltage divider for the reference voltages is a bit off: +410mV and -620mV. Not to worry... - Applied a 1 kHz sine wave with 1 Vpp to the inputs and used the DC-offset adjustment on the signal-generator to tease the circuit. The relay clicks off at the exact values as set by the reference voltage divider. Both channels fine! That's it for today - next step is to hook this up with the amplifiers and finally take a listen... looking forward to that!!!1 point

-

Chemex is sort of special for me and Heather, so Esteban Garcia it is before I go see her for the first time in a month. 16:1. I do the chopstick trick with Chemex. Bloom, draw, then fill to desired water weight. This is some active coffee! Ground off frozen on the SSP. I seem to have finally gotten a good grind size with Chemex though: usually it’s either slow or fast. I don’t time Chemex. It’s also a fucking good cup of coffee. Lemon and cream and chocolate for miles. Super clean (Chemex, after all). Chocolate (again). No bitterness. The lemon brightness is not acidic at all. Soft on the palate. Sweet. I’ll miss this coffee when it’s gone. SSP burrs a little coarser than I do V60.1 point

-

1 point

-

1 point

-

1 point

.thumb.jpg.6d5cf025643d5952563f924f9e007961.jpg)