Leaderboard

Popular Content

Showing content with the highest reputation on 12/19/2021 in all areas

-

After several years layoff I have built a KGSShv Carbon which uses boards I had in and 4 Cree sicfets from several years back (luckily). The power supply is KGSShv v8 and the amps Carbon v6. It has been one of the easiest builds because of a different way of making the cases which I have described in Making diy cases, https://www.head-case.org/forums/topic/18892-making-diy-cases/ It is set for 400v supplies and 17mA output stage currents. It does not get particularly hot in a 20o C room, the heatsinks run a max of 40o at the centre. The power supply pass transistors are bolted to the bottom of the case and the case runs pleasantly warm to the touch. The size is 335 W x 314 D x 155 H inc feet. Weight 8.5Kg. (13in x 12.4in x 6.1in, 18.8lb.)7 points

-

Now my Emission Labs tubes finally have gotten a dedicated DHT amplifier. Picture is taken in almost complete darkness, so most of the light comes from LEDs and tubes. Current is 27 mA which gives a voltage of 15V cross cathode resistor. Filament transformer is on the bench behind the amplifier - I have to find a more permanent solution I guess…6 points

-

5 points

-

You lost me at K-cups at work. UNSAT. Make coffee at home, put coffee in thermos. Tell K-cup to fuck off, with prejudice.4 points

-

Cases and heatsinks are a problem for DIY builds. Front panels of thick alloy need machining and tapping as do heatsinks. These items are hard to get machined or the sizes the builder wants are not available. I devised a way of making cases, which eliminated these problems and made for easier case design, lower costs and quicker builds. Cases Made from sheet aluminium alloy of preferably 3mm so only single sheet of material needed. I get the parts laser cut by a company which will also supply the material. The case parts need holes to be countersunk where necessary and are then taken for surface finishing, (bead blasting and anodising in my case). I then take the front panels to be screen printed with the graphics I provide. The assembly is with corner posts and angle brackets cut and drilled, and bolted together. I only drill and tap corner posts to attach base and top panels. The case is basically a box with a front panel on to cover the front of the box. Heatsinks https://uk.farnell.com/amec-thermasol/fch505010t/heat-sink-50mmx50mmx10-25mm-ceramic/dp/2499023 Edit; a link to these was omitted, http://www.amecuk.co.uk/ Element14 has them in many countries. https://www.newark.com/c/cooling-thermal-management/heat-sinks?brand=amec-thermasol I discovered porous ceramic heatsinks and realised that these small, light, self-adhesive items would solve problems. I bought a few and tested to see if they did what was claimed. A single 50mm square of 10mm thick could dissipate 5-10W stuck on sheet aluminium. To make heatsinks you only have to bolt the semiconductors directly to the 3mm plates and place the ceramic heatsinks as needed. They are not expensive, and with a range of sizes you can arrange heatsinks of different shapes. I was concerned that they might unstick but the opposite has been true, they are hard to remove. They are not pretty so I contain them inside the case and organise slots above and below to act as a chimney to allow convection. This works well and they do not run hot. The porous ceramic devices are very effective. I have found that this method is much easier to procure and build. The amplifiers built this way can be smaller and lighter.3 points

-

Norma Jean Mortenson, before she became Marilyn. Aged 20, in Kodachrome in 1946.3 points

-

It's alive 😊 How does it sound? Sounds great - to my ears... whatever thats worth! Seriously: after a short listening session, I am very pleased! Dead silence with no sound input and a very clear sound reproduction. In my opinion the HD-800 are very good in emphasizing any shortcomings in recordings or audio gear for that matter. Is it better or worse than others? I can't really judge. It is what it is and I am having fun during the process of building it - that's the main goal of the project! I will be performing harmonic distortion measurements as soon as I have the PSUs built. That will be the next step! Probably a Goldenreference variant. @kozard happy to share details - wasn't aware that it's of interest: three tools involved here: first is a 0.1mm V-shaped carbide engraving bit. Dirt cheap on eBay. That's for milling the isolation traces at a depth of 0.05mm. I used the same setting for the surround cutout. Only for marking, did the actual cutout with a hacksaw and a file. Then I used a 2mm endmill for clearing out the isolation areas around the 230V traces. Finally I drilled all holes with 0.6mm carbide twist drill. Didn't bother with tool changes for the different hole sizes. Did the ones that needed bigger holes later on manually. Thats really all the magic. I can maybe document the whole process in detail in the future if there is demand?2 points

-

Finally I got round to getting some time in the workshop: the DC protection circuit is up and running! I decided to do a prototype on my CNC. Converted Gerber files to Gcode with a software called FlatCAM - free, full of features and easy to use! Quite pleased with the result... Assembled and tested: - power on delay ist about 2.5 seconds. I might want to increase that a bit. - The voltage divider for the reference voltages is a bit off: +410mV and -620mV. Not to worry... - Applied a 1 kHz sine wave with 1 Vpp to the inputs and used the DC-offset adjustment on the signal-generator to tease the circuit. The relay clicks off at the exact values as set by the reference voltage divider. Both channels fine! That's it for today - next step is to hook this up with the amplifiers and finally take a listen... looking forward to that!!!2 points

-

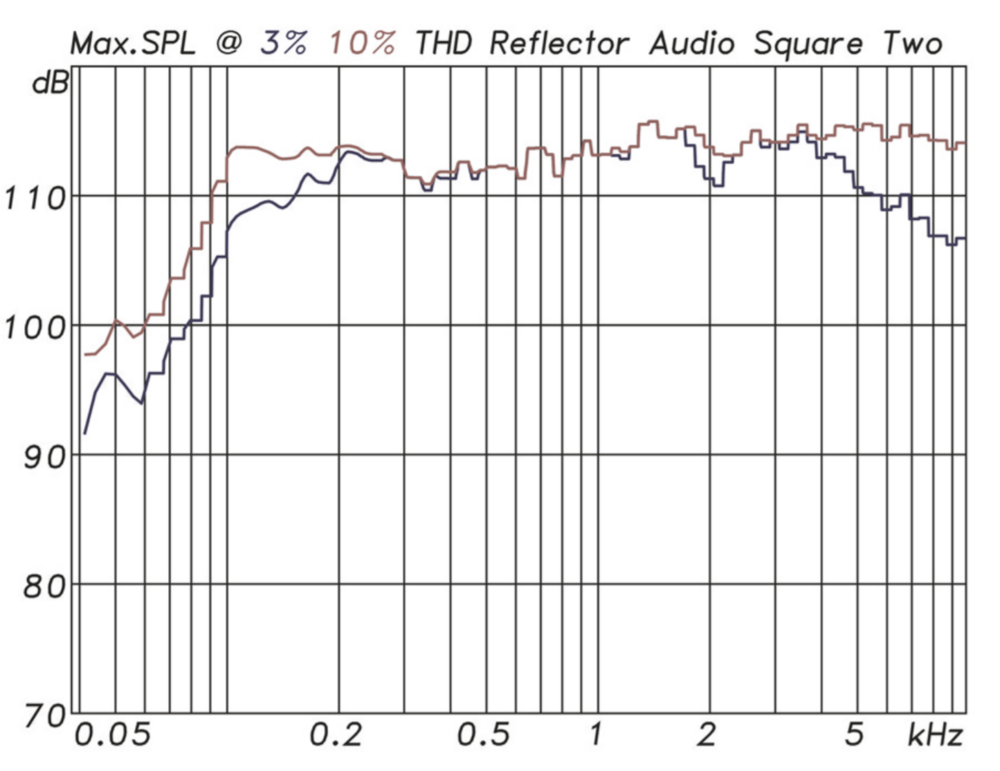

My speaker is called the Square One and the more recent one is Square Two. Both run the compression horn down to 1kHz with very shallow filters. I've seen people using the same driver down to 500Hz, but the horn needs to be pretty massive and you need steeper filters to stay out of trouble. Mine has F6=35Hz while the Square Two seems around 40Hz both in free field. In living room conditions with boundary gain help mine can do 30Hz pretty decently. At the same time there's plenty of headroom for something that's essentially a 12.5" cube. Help it down low with a decent sub and you have almost PA-like SPL capabilities.2 points

-

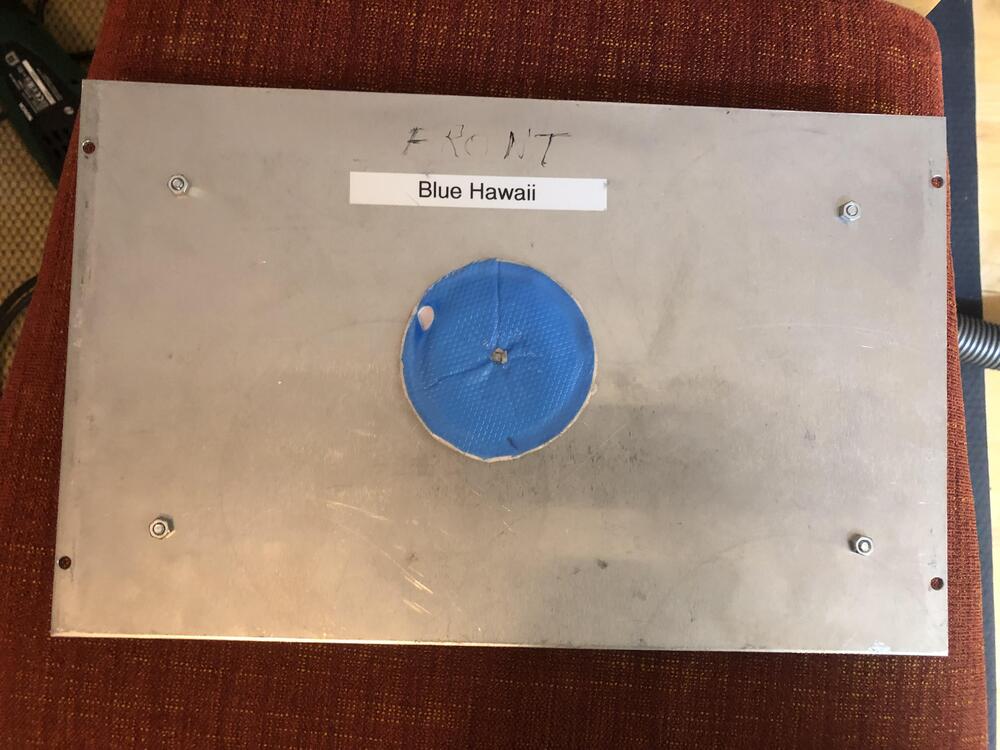

Here is my solution for filament transformer… …mounted on bottom case plate, belonged to a now retired Blue Hawaii. I also found a piece of Bergquist Gap Pad for the transformer to rest on. It seems that cathode resistor voltage is much lower for Emission Labs tube than for EL34, so I decreased the negative high voltage from 460 V to 400 V. The lowered voltage called for change of Cathode resistor and trimmer, now 402R resistor and 100R trimmer. A few things had to be removed before component changes.1 point

-

I'm such a pleb. I was cleaning out my car, and found some 3 year old coffee from when I went to the office. Ground. I tried them. The Allegro Organic Sierra Espresso was fine. Tasty even. I'll finish that, and probably buy some more. The Wegmans Organic Specialty Espresso was not fine. I threw it out. I'm not really tasting anything off with the decaf, but I don't drink that by itself, so I will continue to use it. I know, y'all are cringing right now. Sorry.1 point

-

Thanks for sharing your thoughts. I have a reusable K-cup I've toyed with. I have been with my company north of 30 years and always had an office. Now I work on a trade floor and literally have what I call a 4x2. One file drawer on rollers. No excuses as I don't feel the need to apologize. Just not much space for my things so I keep then in my briefcase that comes in and out with me. On to our regularly scheduled programming... Onyx Honduran Edgardo Reyes via the Chemex. A very nice cup with some tropical fruit notes..some nuttiness and pleasantly sweet. HS1 point

-

Thank you all for welcoming me into the age of fragile hips and knees.1 point

-

1 point

-

1 point

-

1 point

-

You guys are really missing out. One of the better remote videos I have seen.1 point

-

The drivers are actively filtered, so the slopes must be rather shallow to get no phase shift. I have listened to the prototype which had different filtering and power electronics. The sound was superb! The mains in my system are of similar principle, only they use Scanny 15MU midwoofs and the same Faital HF1440 CD. The mids are nicer on mine and they go louder - circa 120dBSPL peak at 1m. Got their acoustician to come to my place and dick around with SMAART to tune them to my subs and room. Haven't heard this kind of percussive transients outside of [very few] pro studio control rooms.1 point

-

1 point

-

1 point

-

0 points

-

Everyone's favorite hyperactive, high-pitched tech dropper reviews a pair of overpriced and underperforming air pods.0 points

.thumb.jpg.7bddf5f4fb06475c0f17e75cb94fd591.jpg)

.thumb.jpg.91dde704b7aa0babf65741a0738fa582.jpg)