Leaderboard

Popular Content

Showing content with the highest reputation on 06/05/2022 in all areas

-

Not today, but yesterday: Yumi accepted a job in Durango and we are under contract for this place. Higher interest rates and COVID pricing is a bitch but at least we’re not buying in CA. Time for another HC meet? We got a big basement god people to crash in. https://www.zillow.com/homedetails/96-Walker-Ln-Durango-CO-81303/13939794_zpid/?utm_campaign=iosappmessage&utm_medium=referral&utm_source=txtshare9 points

-

the telarc recordings were half speed mastered with no transformers in the signal chain and a frequency response down to 12hz or so with no compression or limiting or any type. They tried to get the entire signal chain as high quality as possible and muck around as little as possible, right down to using only using 3 high performance microphones and not multi milking, spot lighting etc. They designed for proper hifis and not for the average consumer grade kit. The soundstream digital system also sampled at a higher frequency than the competition (or cd), and unlike early cds, telarc could actually do editing and splicing digitally whereas all the major record companies took the digital recorded it onto analog tapes edited the analog tapes and then played the edited tapes and digitally re-recorded (but still lied and claimed the signal chain was DDD throughout)... or recorded on their didital system and then converted to soundstream edited and then converted back. Even when DAT and proper computer editing took over the sample rate was higher than cd and had to be down converted and anti aliasing filters applied... the stream of data off cd also has a delay between the right and left channels. many early cd players did not correct for this which I think was one of the reason the treble was so sharp on the early cd players. A few high end players ended up having two dacs and a time delay circuit to realign the left and right channels. But I never got to hear one at the time. In many many cases the record companies transferred analog masters to DAT, and then threw away the analog master tapes... DAT had almost no error correction built in and a few years down the line the DAT tapes were unreadable and the master tapes were gone. So many of the cd reissues of classic analog recordings where actually digital recordings from the lps anyway, and the lp system they used for play back was garbage, the "remasters" sounded bad then and they still sound bad now. I could make far far better recordings from my lp system going through a dcs 905 adc at 24 bit 192Khz sample rate. Telarc digital on lp vs philips "remasters" of classical lps on cd... no contest. I played the telarc 1812 no issues on a decca black with decca pod, modified tie wire system and a proper line contact diamond. My ortofon cadenza bronze has no issues either and thats a moving coil. Both on a heavily tweaked haddock 242 unipivot arm. (ALL hadcock 228 arms had incorrect geometry and the aluminium arm tube versions lack the weight to properly press down on the inverted uni pivot)). And of course ALL telarc sound stream recordings have to be down sampled and anti aliased to go onto cd... The sound stream digital was far better sounding than the early Philips PCM - which DID NOT have even 16 bit resolution... it was about 12-14 bits + deliberately added noise because the 14 bits was not that linear and low level signals had about 25% - 75% distortion and looked like square waves.. apologises for incoherent rambling but for me the message from sound stream was make the record chain as good and simple as possible, make as few compromises as possible and don't muck up the sound with filtering or compression and aim for an audience with proper hifi... lessons many recording companies never learned and still need to learn today. I also wonder if the average person listening to music through their mobile phone gets higher auto quality than the average person in the 1960s or even 1950s... (when a good hifi seemed to be a part of most middle classes lives). I have listened to a friend playing some music through some cheap Bluetooth speakers via their mobile and I seriously wonder if (apart from the surface noise) the sound was better than a 1940s 78 on a good player. James4 points

-

3 points

-

Lol! I’ll be staying at Rice, at least for the foreseeable future. Would need to switch fields (data science/AI/machine learning probably) and get a work from home job to move out there permanently. I really only need to be at Rice during the fall and spring semesters and can probably visit once a month during the fall semester.2 points

-

2 points

-

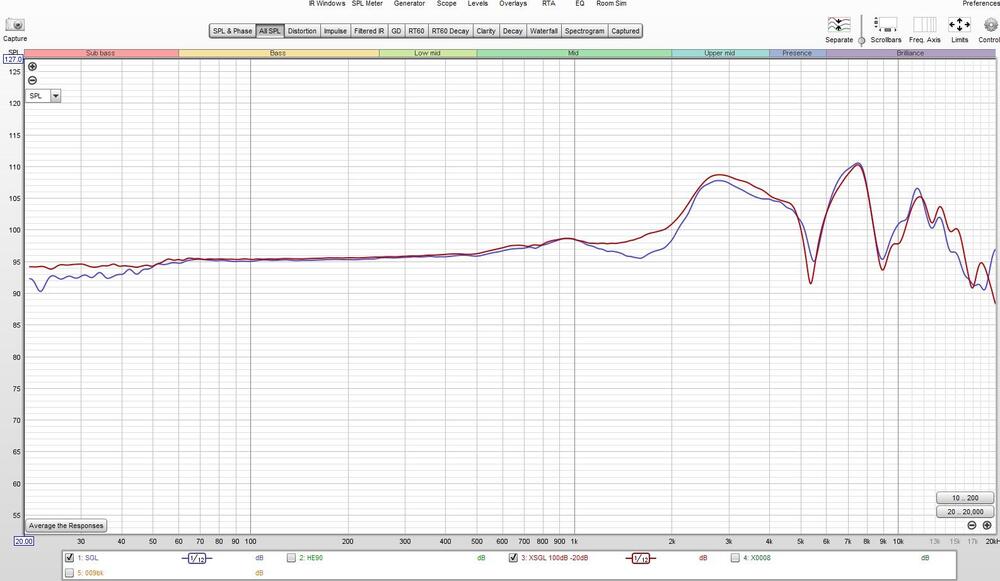

It started with repairing a badly damaged shangri la jr driver 2 years ago, I almost rebuilt the set from the diaphragm to the stators,and of course the dust cover😦 The first thing I discovered is that the 'nano-technology' used by hifiman actually comes from the covering used by indoors aircraft model enthusiasts,the name is OS film and it is still available on ebay or https://www.indoorffsupply.com/shop/os-film-25ft-roll-1 the driver of the hifiman estats is completely glued which is similar to the early stax lambdas, but hifiman glue is significantly worse...after opening the driver i found that they only use OS film for their dust cover, the diaphragm is another PET film ~ a little bit thicker but with much better strength. In order to repair the diaphragm, I found a seller on Alibaba who can provide samples of Toray PET film with thickness below 2 microns at an acceptable price,and use the inner tire stretcher to stretch the film like any other diy estats ,Then test it with a 10" subwoofer and minidsp umik-1 to find proper F0. conductive coating is another serious problem,I've tried quite a few methods including antistatic agents like licron crystal, ANTISTATIK100,floor cleaner,carbon-based coatings such as graphene, and alcohol-soluble nylon, even tried nano-silver wire solution and metal evaporation...Some of them are sensitive to humidity, some arcs,some are ridiculously expensive, some have uneven surface resistance distribution, and some are sensitive to temperature changes. Yah~ finding the proper conductive coating is the most difficult part especially for a layman. unexpectedly, I tried to search for hifiman patents, hoping to find something useful... here's a patent showing that they used some kind of metal oxide nano particles as conductive coating for their estats. emmm,very interesting...🙄 By consulting with chemistry professionals, I decided to try a solution called ATO (antimony doped tin oxide), there are many antistatic agents I have used before have ATO ingredients though. I got some ATO alcohol solution at concentration around 10~15%, it works really well, and coating appearance is somewhat identical to hifiman diaphragm! The last thing is to repair stators. hifimans probably use #150~300 brass mesh and solder their edges to a 2mm thick aluminum base plate PCB board, then glue the rest of middle part. I've tried tensioning those brass mesh with embroidery frame and manual screen stretcher,but it is not tight enough to stretche brass mesh in this way, the mesh itself is too strong to tighten it up... then I found some brass sieves with different meshes on taobao and these machined copper screens are perfect for making DIY mesh stators... after everything's ready,i desoldered OG brass mesh, cleaned the copper foil, applied low temperature solder paste, and carefully soldered the new brass mesh with a heat gun. During the process of repairing shangri la jr, I started planning to make some bigger mesh stator estats... of course,the target is its big brother shangri la SR😈I received a set of the first batch of shangri la sr made in 2016,here is the headphone inside,yap~inherited the tradition of hifiman with such horrible workmanship...😱 however,SR sounds not as technical as the X9000 though,but with more pleasant and passion. SR uses 3mm thick aluminum base plate PCB instead of 2mm on JR version,2 black things in the middle are to prevent the diaphragm from attaching stators,The D-S gap is around 0.7~0.8mm(thickness of glue included) which is identical to JR version,active area is close to 6400mm² ,that is pretty large diaphragm size for a commercial product though,but less 5300mm² of area on stator allows air to pass through. I tried to use the 3mm FR4 board as mesh holder at first time,however,mesh stator disassembly is not an easy job...therefore,I changed to use 1.5mm brass plates as the mesh holder and glued the copper mesh to it , brass mesh is also replaced with higher # red copper mesh for more convenient adhension. I spent most of time adjusting the tension of the diaphragm and finally found the tension needed for F0 similar to OG SR ,the clone driver has a slightly enlarged diaphragm(6839mm²) ,0.73mm fr-4 pcb spacer, and everything is screwed to the housing cover. The frequency response of clone and SR are generally similar,but the sensitivity difference between the two is about 1.5dB actually,SR is more diffused...clone one sounds a bit more clearer. SR has obvious recession between 1-2kHz,it may be caused by a sealing problem in the space between the driver and the earcup.... It's unlikely to be solved without EQ, but it doesn't sound as bad as it looks from the graphics. one more thing... Every shangri la must have a throne , so I made one for my mutation🤣1 point

-

Well I think we are already Vermonters as we went shopping in New Hampshire today.1 point

-

It is likely that the #80 mesh is not easy to make a stator by hand, which leads to the failure of the omega driver, and the driver housing made by resin at that time was not as strong as later 007 009 though. There are some DIY estats such as Perun and Phenomenon in Russia, they use much lower number size copper mesh as stator. I have owned a pair of perun, the stators are made of about #10 copper mesh, the mesh itself is very strong actually, and is glued to the PCB holder with structural adhesive. As for the glass stator of the HE90, the glass is indeed rigid, However, as a stator, it does not play the role in the Sennheiser advertisement at all. The only thing I can expect is that the glass is chemically stable and not easy to be corroded or oxidized, and Manufacturing microporous glass plate is extremely expensive which also leads to the insane price of the HE90... Unfortunately, Sennheiser is now not planning to stop, they use even more expensive ceramic based PCB stator on HE1.😦1 point

-

When I was a kid we had a Chinese restaurant in Anchorage named Dynasty Restaurant. The sign was lighted, but the Y was burned out. It stayed that way for years. I guess it didn't hurt their business too bad.1 point

-

Friggin' sweet, Shelly! That semi-octagonal shaped room would be great for acoustics...or terrible, I don't know. Might be easier to defeat the single node if it's a regular octagon...1 point

-

1 point

-

1 point

-

1 point

-

if you are using a multimeter with a 10Mohm input impedance then you will not measure the actual voltage. The stax bias output is very high impendence i.e. provides very very little current and so even the current draw of a 10Mohm multimeter will load down the bias and you will measure lower than expected. Either you need a meter with a Gohm or higher input impedance at 1000V or you need to measure before the current limiting system on the bias output. For example the golden reference HV power supply bias circuit has a 4.7Mohm current limit resistor just before the output so you need to measure before that limiting resistor and of course be careful because if you multimeter can't handle 580V or you touch the probes etc you will get a non-current limited 580V DC shock which is not going to be good for you. incidentally I get about 378V DC at the socket on my diy T2 (pro bias only) into a 10Mohm meter BUT this value is going to be very dependant upon the value of the current limit resistor in the bias circuit. So if you amps current limit resistor has a lower value then 420V is not necessarily unrealistic.1 point

-

I have been getting back at this..working up to a limited run of these as the STAX SR-X9000 and Audeze CRBN have made that need to happen. But the chassis is extraordinarily expensive and difficult to produce, so I am working at ways to fix that. Also need to put it on the scale, thought it was 45lb but feels more like 60lb haha. It's really not that big of a footprint (13.5x18), but it makes the BHSE look like a toy. Power consumption is 190-200W depending on tubes, with 90-100W of that being heaters. The bottom of the amp is ice cold and the top is pleasantly toasty. The first 3 stages have recessed slide switches on top to switch 6.3 to 12.6v heaters, so common tube types are: 1st: 6SN7/12SN7, 12AU7 and many others w/ 8 to 9 pin adapter 2nd: 6SL7/12SL7, 12AX7 and many others w/ 8 to 9 pin adapter 3rd: 6N6P, ECC99, 12BH7A, possibly others such as 5687 w/ pin-out adapter 4th: Emission Labs 20B-V41 point

-

1 point

-

Patty Gurdy -- Irish electric hurdy-gurdy playing ginger Her collaboration with symphonic metal band Scardust is fantastic -- I love the Celtic influence (I love the goofball bassist and silly drummer faces, but I relate more to the way-too-morose guitarist and keyboardist.) xPropaganda -- 80's band Propaganda reincarnate with ZTT and Stephen Lipsom -- synthpop with MILFs, Dusty like:1 point

-

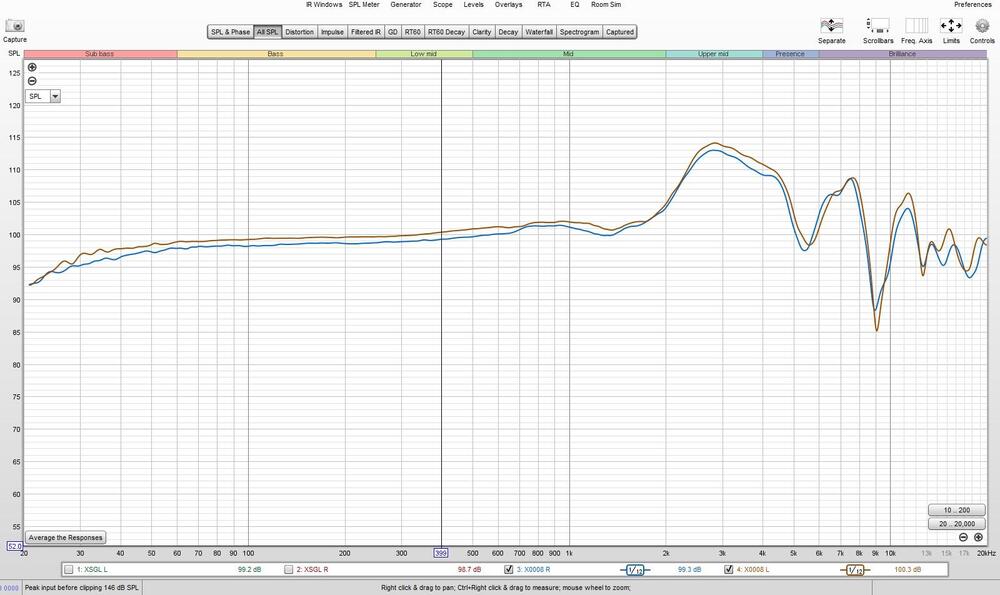

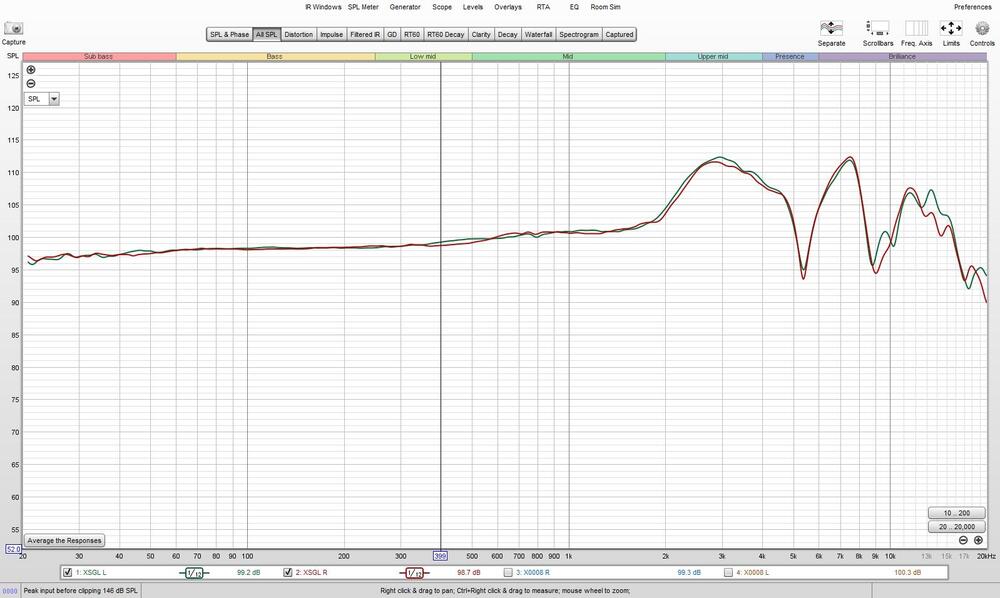

I did make X-men round driver which has a similar stax 009/s driver housing but a bit larger,and all X-men headbands actually are made with hifiman's damaged headphone parts, however, the yoke is aluminum 3D printed...😈 for comparison, the one on the right is the same size of 009/007 driver housing , the left one is the X-men with 1.5mm brass holder and #200 steel mesh stator in a 110mm driver housing. the stator can cover diaphragm diameter range from 84~92mm,the currently installed spacer is for 90mm diaphragm. I'm now running into some tolerances and earpad material problems....compared with perfectly matched sgl clone, the round estats have about 1dB consistency difference in sensitivity, and breathable fabric earpad causes roll-off of low frequency. this estat is currently on hold...🙄1 point

-

So a unitasker, then. "I have railed against unitaskers for 20 years. I've come around to liking them as strategic gifts for people you don't like." https://www.npr.org/sections/thesalt/2015/12/23/460833325/the-unitasker-kitchen-gadgets-alton-brown-loves-to-loathe1 point