-

Posts

2,292 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Forums

Events

Everything posted by Kerry

-

Happy Birthday Birgir! Enjoy the day

-

Exciting stuff! Glad you were able to get them back in working condition

-

I'd love one. Can I store it with you. I have no room left in my city apartment. I could possibly convert my powder coating oven to a reflow oven

-

Yeah, I may add a spot to support the prebuilt regs with the same chips.

-

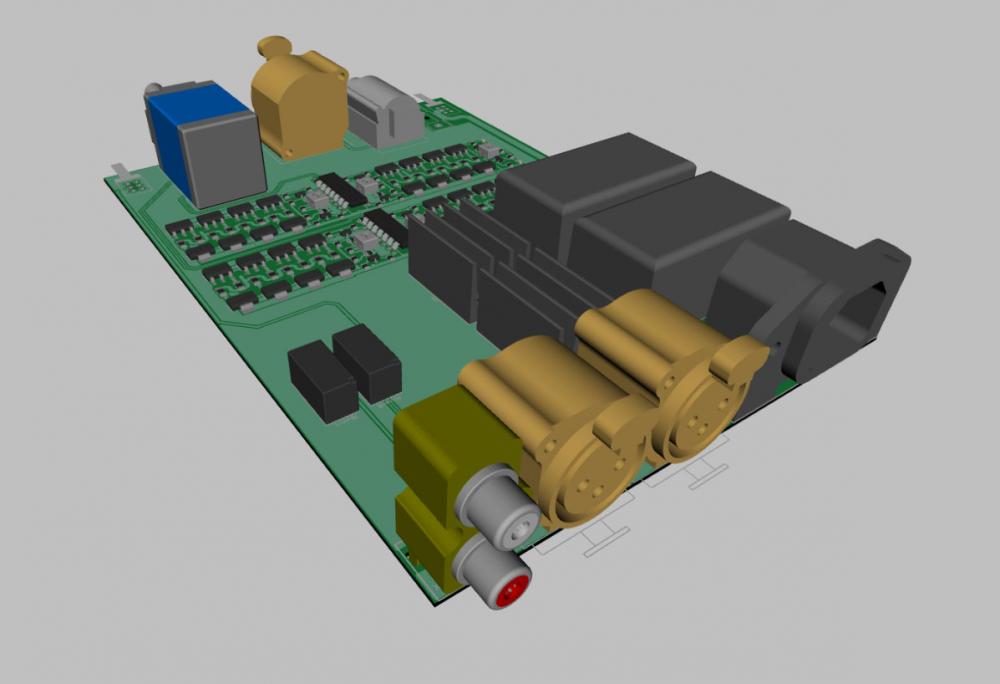

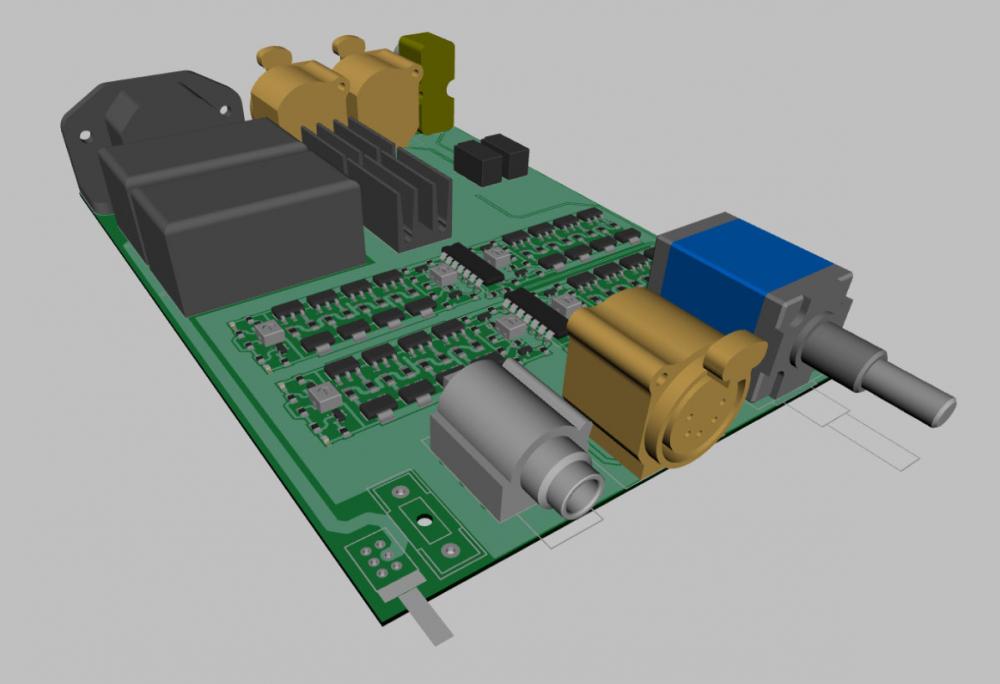

Interesting site for the enclosures. Not sure that I will fit into their standard series 5 boxes. For the trimmer I would prefer 25 turns. I can fit either gull-wing or j-hook. I'm going to use a hot air gun for all SMD soldering. I've got the TPS7A470 / TPS7A33 as second stage regulators. Definitely need to use a hot air gun for those.

-

Thanks. Yeah, the vents don't work so good. I was thinking of something like FPE with the 1U side panels, but may from eBay.

-

I've been listening to all kinds of music today, but currently listening to Donna Summers - On the Radio. It's making me laugh. Good classic disco

-

Yeah, looks beautiful

-

Here's a fun weekend project. It's the Super Symmetry Dynalo. I need some sourcing help on three items. Case - It needs to be 5" x 7" x 1.75" (or 1U) Board is currently 4.8" x 6.8" Trim Pots - I wanted 10K surface mount multi-turn. The pattern I'm using currently is 3A (as listed in DipTrace) Push Switches - I need one for the Power (250VAC) SPST and one for the relay (24VDC) DPDT / SPDT. If I could find the same switch for both that would be great. I'd like a metal extrusion through the front chassis. I've used SPUJ190900 from Alps before, but this would only cover the relay. Thanks Some pics

-

Yes it will Curses... I know where my spare time will go this holiday weekend.

-

Nice work Joachim I've had my eye on this for a bit now and was reading the development forum as it was coming together. I ordered the Z1 as I think it will make a great USB in device. Yes, let us know what you think of the sound. I'm thinking of basing my DAC off of this.

-

Congrats! Enjoy

-

Thanks for the feedback. I'm looking forward to getting the new board installed in the amp

-

Nice! I like that you've signed it

-

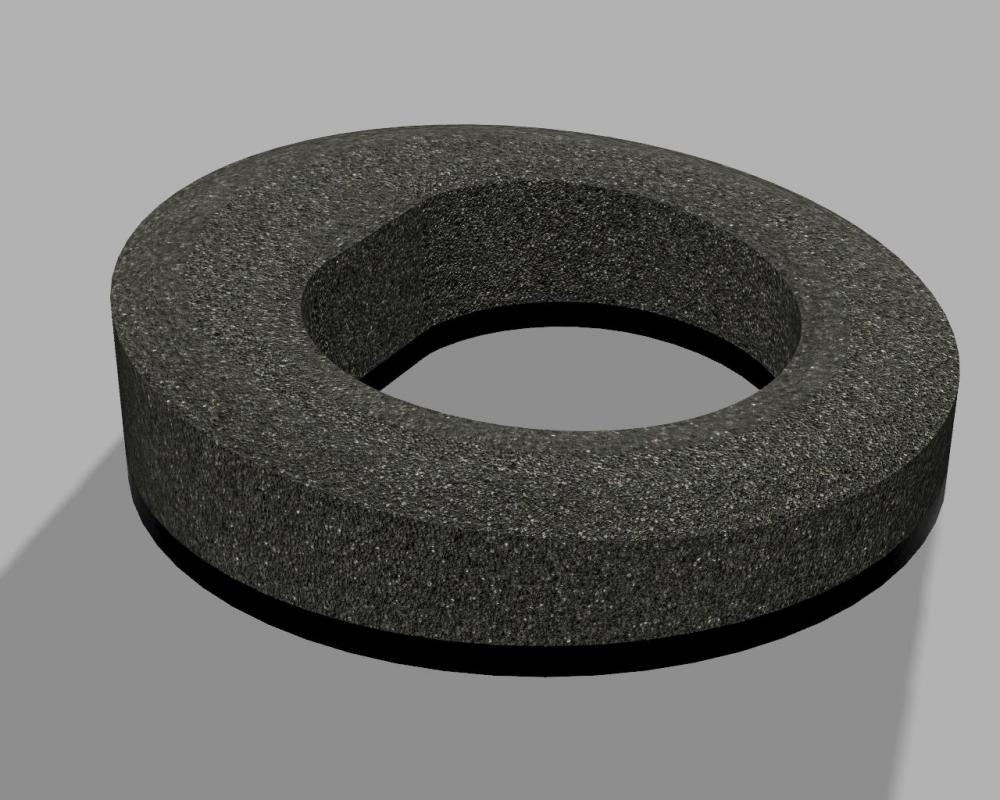

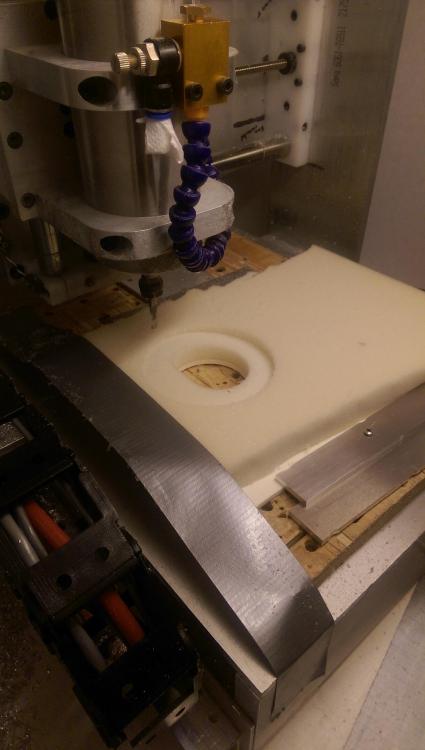

There is an ability to do community projects in Fusion 360, which I think is really cool. For anyone wanting to mill foam, there are some precautions. I had an issue with my initial tests when milling to close to the edge. It grabbed a piece of foam and pulled it onto the bit. Not good. I used the duct tape on the one side to give it some stability near that edge. Like everything in milling, make sure your work piece is secured well. Also, for clean final cuts you need to use conventional milling vs. climb milling. This is opposite for aluminum.

-

Celebrated Thanks everyone

-

^ That's a real win win

-

Thanks! Going out to celebrate on LI. Still recovering from yesterday

-

Thanks. You need to get Fusion 360 and learn how to use it It's from Autodesk and is free to individuals and small businesses. It took me about 3 hours to model these.

-

So I wanted to replace the foam in my 007 Mk1 headphones. I modeled them in up (I love having a mill ) and here's what I got...

-

Congrats on the build! I think you should be good using the 12v supply. Just make sure there is enough current available. I don't recall the requirements but can takes look at some point. I feed the attenuator board off of the 3.3v out from an Uno board. Again, just double check current between the Uno and Nano. The only other thought is whether it might generate some noise into the amp when changing the volume. Good luck and keep us posted on your progress

-

So tragic. RIP Christina Prayers for her family

-

^ This, and Congrats on the build.