Leaderboard

Popular Content

Showing content with the highest reputation on 05/18/2020 in all areas

-

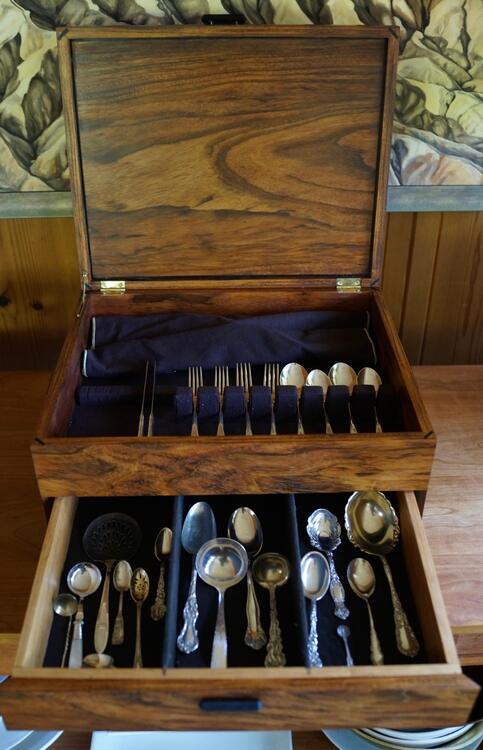

This morning I put the final touch on the silverware chest that Steve and I have been building by installing the insert that holds our silverware set. I bought it from Rockler and designed the chest around it. I'm proud of the chest and think it is beautiful even though it is not completely perfect in every way, and I certainly never could have done it without Steve. We made the chest from a single large board of jatoba wood and it turned out to have some twists and warps that were a bear to manage. Also, it has high mitered corners and my design idea was to wrap the grain from the left side, across the front and continue onto the right side. The lid is also mostly a single piece with sides formed by the sides of the box and an ebony border around the insert. It was by far the most complicated thing I have ever attempted and Steve claims the same for himself. I am going to post a bunch of pictures of the finished product, but not the blow by blow building shots as I did with the dining table from last month. I don't want to bore everyone and I don't have many photos anyway. The only two parts that I am going to highlight are the lid and the horizontal routing we did to make an ebony inlay on the edge of the drawer opening (which covered a mistake we made earlier). The lid piece was too big for my router so I had to build a router sled and route it that way. The first pic shows the setup with a dummy board, the second the jatoba board while being routed, and the third pic down shows the board after routing and a first sanding. It was a cool exercise. The horizontal routing was done on the router table Steve and I built, which can be tipped 90 degrees so that the bit extends outward horizontally, duh, and allows for tenons to be cut precisely. It worked great to make a slot for the ebony insert that is exposed when the drawer is pulled out. Lastly, here is the box when we glued it up with the lid still part of the box. Steve's plan all along was to build it this way and then cut off the lid an inch down from the top so that it would fit together with the box perfectly. It worked to an extent, but the twists and warps in the wood made it much more difficult to accomplish and not quite "perfect." So, the rest of the pics are just the chest in some detail to show the continuous grain wrapping around the three sides, and the ebony accents and the handles that we made from ebony as well. It was anxiety inducing and I definitely lost sleep along the way (covid is to blame as well), but the results are pretty fabulous imho.23 points

-

I have to say that the whole process, even with it's challenges, was quite enjoyable for me. I helped out when extra hands were needed, and did provide an idea or two, but Al was the real force behind the project. He has gotten so good, in such a short time. It's really amazing! Most of the time I set on a stool watching him work away (I just love hard work, I could watch it all day). I knew from the beginning that this would be a difficult project. Lining up four 8" mitered corners on boards that are twisted and warped is no walk in the park. But I also knew that if Al could pull this off, then he could tackle just about any project. It may not be a large project, but it encompasses so many woodworking skills! A fantastic learning experience, from which he had to correct some mistakes, solve some difficult tasks and come up with some unique solutions. I am really impressed with his abilities and perseverance. Al has also been a stand in for my company lately. As we've quarantined together, and I'm not yet comfortable working next to other crew members, Al has offered on three occasions to be my first mate, so to speak. We've installed a challenging set of kitchen cabinets, built from scratch four closet organizers and installed a floating bathroom vanity into a tiled wall, where the tiles were as hard as diamonds. He catches on so quick, and was just a blast to work with. I'm quite sure though, that he hasn't worked for such a paltry wage in decades. I've been teasing him about getting his pay to him as quickly as possible, in case he's in dire straights. 🤪 My dream is that one day two retired dudes can set up a decent shop and build beautiful stuff. I know how much he'd like this, because he can't get enough of my singing in the shop!17 points

-

That's some high praise from Dr. Wood, and the rest of you, and I'm flattered. He did more than watch, of course, and working with Steve and with Doug has been a great education. Their different styles and approaches have each had an influence and I've tried to meld them into a hybrid. I wish I hadn't mentioned the lack of "perfection" because it definitely got overblown. I am extremely happy with the results, including the things that were challenging and didn't come out perfectly in line with the picture in my head. And as far as setting up a shop, the first order of business is a motion sensor that starts music playing as soon as we walk in to keep Steve's a cappella efforts to the minimum. 🤡7 points

-

7 points

-

I forgot to mention that my brother in law's painting of Death Valley is a nicely complementary backdrop for the chest.4 points

-

Absolutely stunning. I love all the details and the ebony trim. I vote yes for a woodporn thread. Love this, love this, love this! Actually, the only imperfection I see is that I don't have one too. Jealous!3 points

-

3 points

-

Using a King 1000/6000 combo stone for sharpening. If I really ding up the edge I'll rough it out first on some 180 or 400 grit sandpaper stuck on a piece of plexiglass. I've had the Ruike for a bit over 2 years and so far I'm really happy with it. It beats out the old Kershaw/Ken Onion Vapor as the best beater knife I've ever owned.2 points

-

2 points

-

Perfection is the enemy of excellence, Al (and Steve). And to my eye that thing surely is excellent, so don't sweat the lack of complete perfection.2 points

-

Played through A Plague Tale: Innocence, a fun game with shades of Dishonored and The Last of Us, but ultimately felt disappointing due to the amount of wasted potential with the story and setting.2 points

-

That is absolutely beautiful. Again, the craftsmanship is just superb.2 points

-

2 points

-

The mineral oil worked fine for the HF-1 and HF-2 (thanks Bryan and Ryan) and it was easy since I had some in the house. The Alessandro MS-Pro will require more work so I ordered some linseed oil soap (thanks Doug and Al).2 points

-

Ooh - a Transcriptors Hydraulic Reference complete with sweep arm and stylus brush. The only thing that is not original is the SME arm - it should be the iconic Fluid Arm. I lusted after these in the early 70's in a way that was almost painful. https://www.transcriptorsengineering.com/1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

replaced the diverter in my shower, after it broke right as I got in for my morning shower.1 point

-

1 point

-

1 point

-

A friend owns these and a few other Gibsons and such. I only am allowed to take pictures, not touch. 😃0 points