Leaderboard

Popular Content

Showing content with the highest reputation on 09/27/2020 in Posts

-

I'm sorry sir but there's gonna be an additional fee if you want to upgrade to a working plane.4 points

-

Pretty lackluster actual birthday day. Taught my genetics lecture at 8:15, Intro. Research Stats. at 9:45, Zoom office hour 11:00, Research Stats. Lab at noon then stupid paperwork shit until I left work 4:00. Rested for about a half hour at home and then took Peter to soccer practice. The birthday weekend was pretty good. On Friday our new family room couch was delivered and on Saturday, the garage refrigerator was delivered. So all in all a pretty good birthday, and as Al pointed out, much better than the alternative. Thanks for all the good wishes.3 points

-

Got back on the plane after about three hours. Sat longer than expected and then they said there was a new problem being worked on. Apparently that is now fixed and we are leaving again. Soon. Hopefully. All the while in an N95 mask, which makes everything better, of course.3 points

-

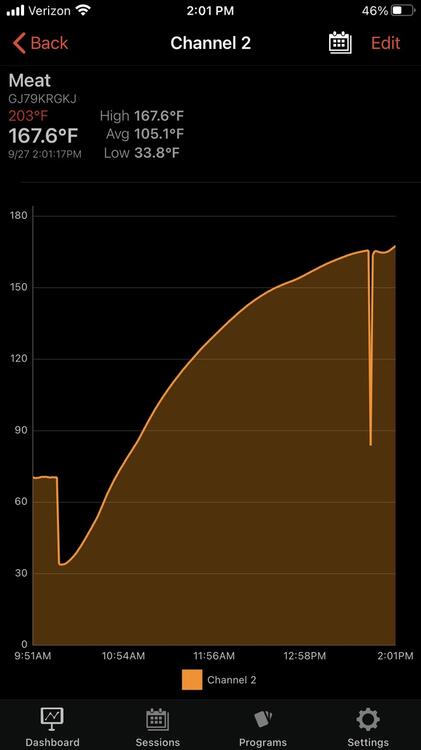

Really liking the Fireboard2 so far. Between it and the Traeger app I was able to monitor today's cook (small pork shoulder) remotely and adjust the temp a couple times to ramp things up a bit so that it was ready to wrap when I got home. The dip in the graph is when I removed the probe while wrapping. The nerd in me loves this. Overall App View w/ the 2ch that I'm running today: It can run up to 6 channels and also has the ability to drive a fan unit for those that use Webbers or Eggs w/ a booster fan. Detail view The cliff at the beginning is that I had the app running while the grill was heating up with the meat probe just in the air waiting to be used.2 points

-

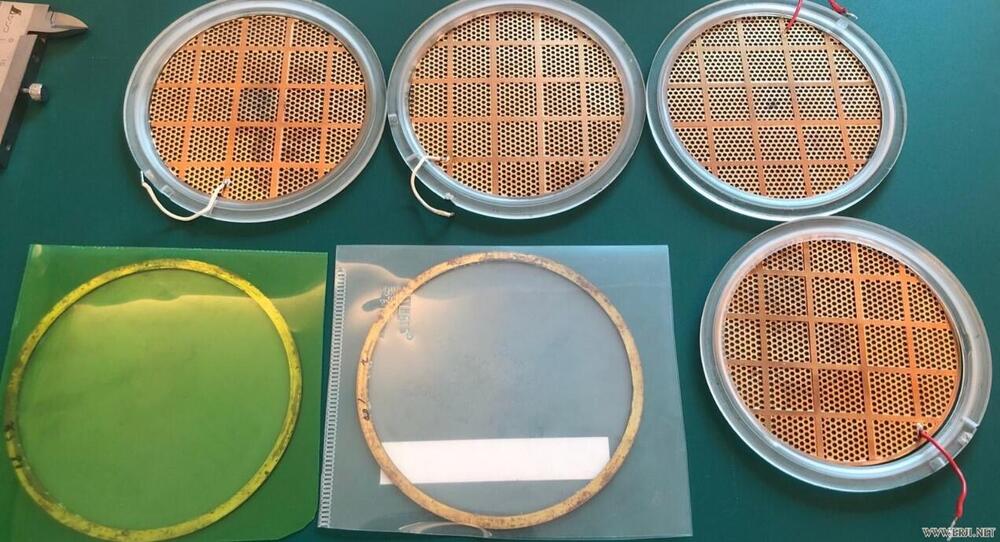

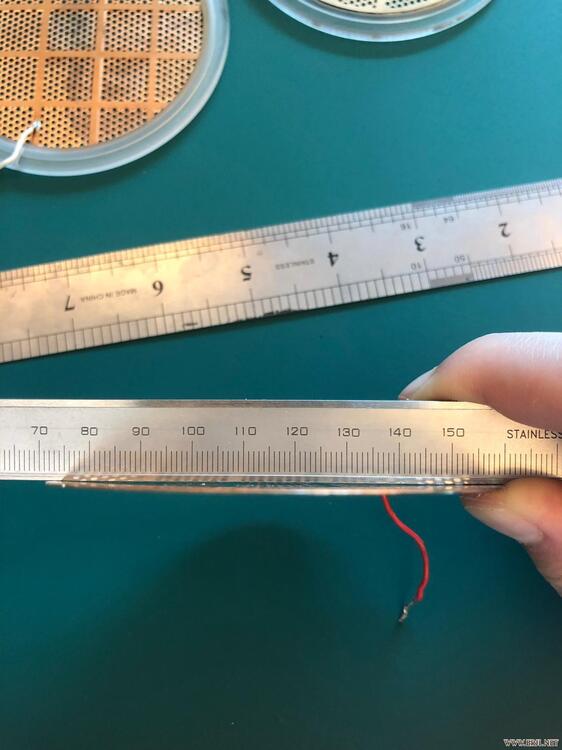

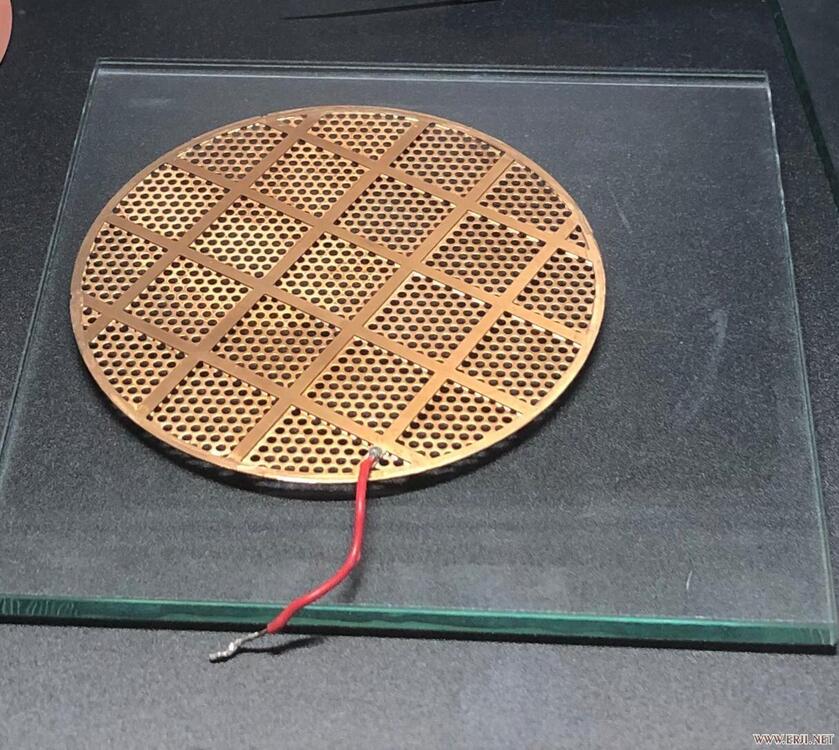

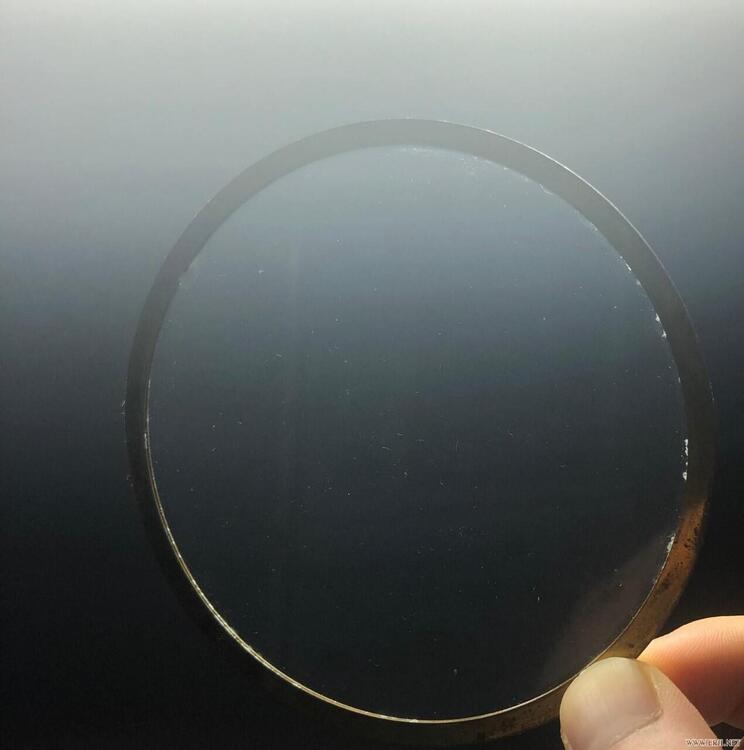

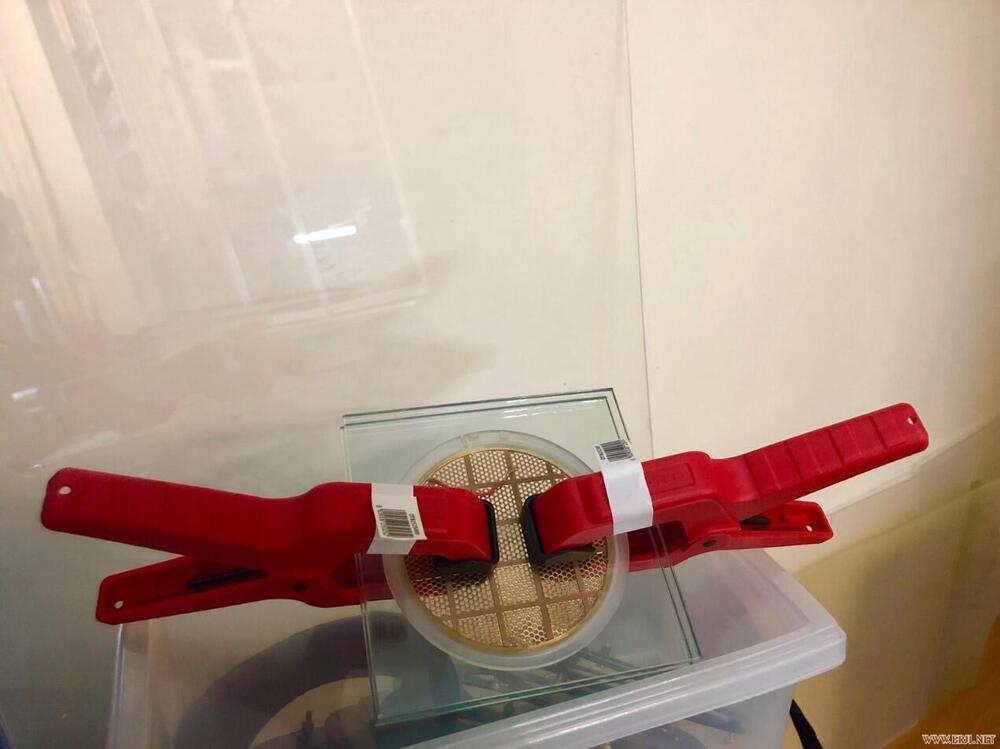

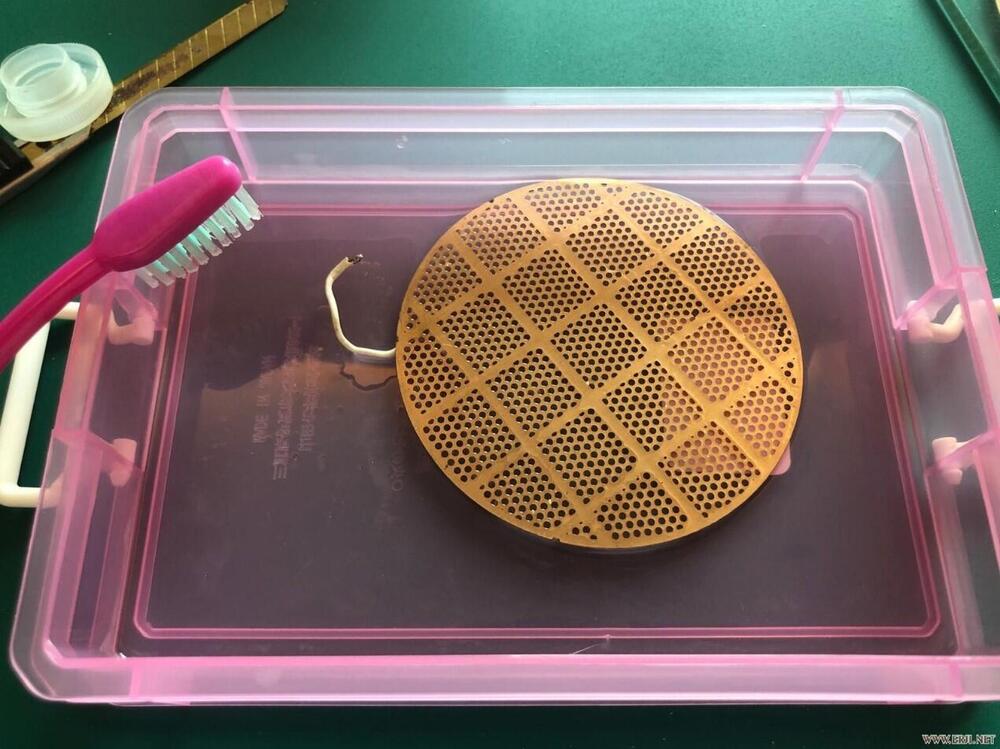

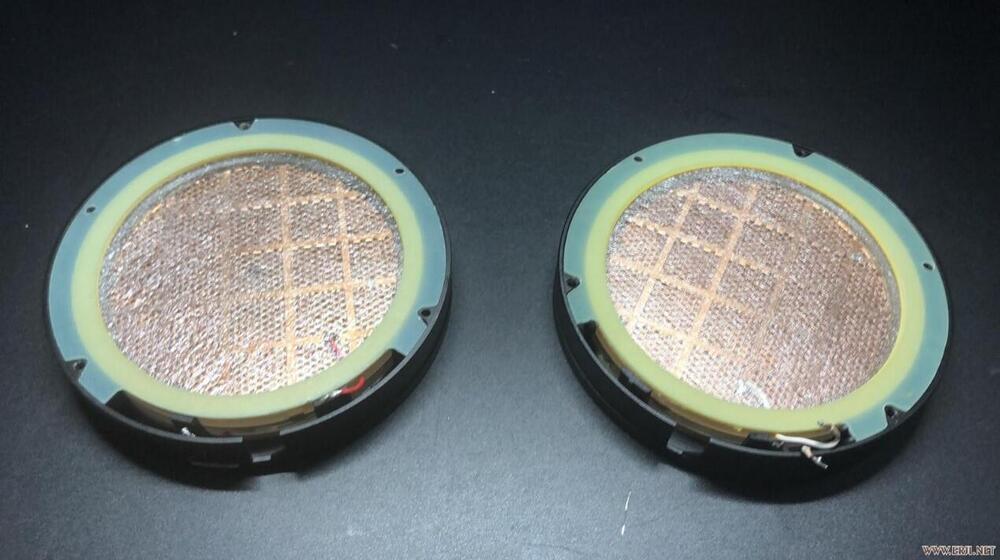

I posted a Chinese version of this article several months ago and now I translated it and put it here. I guess some people here will be interested. I hope you like it. Actually I have some more articles like this pending but I just don't have the time to write it up. --------------------------------------------------------------------------------------------------------------------------------- It all started about a year ago that a second hand sr-omega popped up in the local community. From time to time omegas show up on markets around the world but this one is different: an omega with 007 drivers installed. When the drivers are replaced, such omega drops its value to a fraction of its original. The seller listed it for 48888 RMB initially and sold it for like 20000 + at the end. When I first saw the listing, the first thing that caught my attention are neither the price nor the 007 drivers but one accessory laying aside, which is a pair of dead drivers I have never seen before. At first sight I know that it’s a prototype, a true unicorn that probably only one pair exists in the world. I am so curious on how it sounds and how it compares to 007 or 009 or the original omega. I messaged the seller right away and after some persuasion and explanation that I can give this driver a next life, I got it at a reasonable price. And it has become one of my biggest regret that I didn’t also purchase the omega itself that time, otherwise I can put it back into the place where the drivers belong to. Here is the driver itself. From this driver you can see several innovations made by Stax that has never been seen in other Stax models before it. The diaphragm is identical to a normal omega but the electrode is totally a different creature: copper plate similar to lambda sig etc. but much more refined. Over different regions of the electrode the thickness is different. The thicker copper comprises of the # pattern skeleton to give the rigidity while the thinner copper is perforated. You can see the same topology on 009 and 009s where they claim to have the MLER welding technology employed on the electrode. But this omega prototype electrode is in one piece and just as thick as a credit card. Furthermore, they rounded the edge of the perforation like what Stax does on 009S. Stax even make a sectional view illustration graph on their 009S promotion leaflet. Such treatment helps sound to radiate. To me it’s really impressive to see some characteristics of a flagship model today on a 30-year-old design. But Afterall it’s a prototype. It does have some problems: this electrode is too thin to give enough rigidity and prevent bending. They are curved to 5 o at most. Moreover, the area of attachment between the frame and the electrode is too small. It just peels due to aging. I see such defects in some modern designs too. Although its reasonable to have these issues because its 20+ years old, it does reveal that the one who designed it is not thoughtful enough. Perhaps that’s why it was never released to the market except the one on my desk. Besides the defects the design has, the driver itself is at a very bad condition. The drivers have been exposed to the external environment, so dust gets onto everywhere. The one who does not properly seal the package probably has never imagined that this driver will be repaired. It’s a pain in the ass to make the driver dust free again, especially when they are on the very fragile diaphragm. Normally I don’t accept requests to repair an exposed driver and I will give a new quote to clients who send me an exposed e-stat without telling me in advance . But I own this driver and I can bear the risk so that’s OK. The four electrodes are bent in different direction and magnitude as well as having detachment and failure of epoxy. Taking it apart and bent it manually is the only way out. It takes a lot of skill to bend a bent copper plate. Like you have to apply a certain amount of force on the copper and then you check how you have bent it by eye balling or a ruler, and you repeat this process a dozen times on one plate. You make it worse if you don’t know how. The most challenging part of it is that how much you bend an electrode actually affects the sound pressure on one side of the driver so at this point you just have to guess. I have neither the tool nor the file of the design, its all hiding in somewhere inside Stax’s archive library. At most of the time repairing a e-stat is more challenging and troublesome than making a new one. Aging will just make everything a mess and sometime you have to wipe the ass of someone who does not make the design good enough to withstand usage. Solvent removes dust and grease on the driver. It gets much trickier when it comes to cleaning the diaphragm. Effectiveness of a method to clean the diaphragm is an issue when there is just too much dust, not to mention the risk that you will break a diaphragm by puncture or sketch. At the end I decided to clean the diaphragm with solution. Although it will damage the coating, it means nothing to me as I can recoat it anyway to replace the old one which is probably damaged anyway. Cleaning done. They took away the dust screens so I have to prepare these as well. Last Step: assembly, the most important part of all steps. This several hours of work determines how long a driver can last before imbalance or noise occurs. Its my duty to make sure every edge and surface inside the driver is dust free. If not, dust will eventually get onto the diaphragm at some point in its service life and short the electrode and the diaphragm. Practically if the pollutant is much smaller than DS gap 0.5mm then its fine. All these procedures are done in a dust free environment. Soldering work Omega adopted a spring mechanism to connect the bias supply to the diaphragm. It is shaped like a tuning fork and it is odd (photo credits to audiohobby .pl ). I tried to make one but it just can’t grip firmly. After some days of having this troubling me I figured out a way, using HD600’s spring and I glad that it worked, at least for now. I used 007 cable, lambda sig headband, cnc machined and anodized aluminum casing and tailor made earpad. I am a proud Omega owner and I shipped the earpad for a clone. The result is satisfactory. I took away the back grill for inspection but I am kind of regret because I cannot put it back. The general sound signature of this omega prototype is somewhat identical to the original: natural, airy, transparent and clean. Its free of unnaturalness which can be found on 009 (please forgive me if you find this statement irritating, afterall the perception of sound is subjective). It has a larger soundstage than 009 for sure but I think 009 has more details than this one slightly. To me this prototype takes a midway approach between early-SN omega and Late-SN omega. It has a bit of the sweet coloration of an early omega while having much of the naturalness of a late omega. I found that early omega has a huge, diffused soundstage while a late omega has some in head effect which is unpleasant to me. Luckily this prototype is more on the early side. But still this prototype is different from the two regrading the proportion of width and depth of soundstage. I can’t explain more because I haven’t AB compare yet. What amaze me the most is how the prototype omega differs from the typical omega in the dynamic and bass region. The normal omega gives me an image of mellow, soft and relaxing in the bass region. Although 009 and 007 has better bass and impact I like the stress-free presentation of the original omega. The only thing omega put stress on me while I am wearing it is its price. In the prototype omega, I feel an enhancement on the impact, the speed and the amount of bass. Perhaps it’s the reason why they create this prototype, to improve on what the original is lacking. The density of imaging of sound also improves by a bit. Be caution that I cannot remove the effect of the different earpad and casing on the overall sound comparing to the original so the effect I mentioned above might be due to them. Despite all these merits, there is something lacking in this prototype: The openness of soundstage and the super-revealing details on the original omega. If omega scores 100 and 009 scores 85 in the aspect, I will give a 95 to this prototype. The transition from mesh electrode to plate electrode seems to be a double-sided sword. I remember in one of the Stax staff interviews they explained on Pros and Cons between mesh and plate electrodes. You give up something to exchange for another. Nothing is perfect unless you pay a double.1 point

-

Nah, it's an old repair tech trick. Helps quite a lot actually if you have the proper technique. 🤪1 point

-

1 point

-

You have made so many awesome things, for me and in general. I can't imagine you talents not being used, so hu-rah! Also, wouldn't it be easier to install the replacement without your fingers crossed? Of course I fully admit to zero knowledge in this field.1 point

-

The times that we've flown together have gone off without a hitch. I must be your lucky charm. In the future take me wherever you want to fly. Problem solved. You're welcome!1 point

-

Decided to finally see if I can fix up my HP 3582a spectrum analyzer that's been out of commission for a while since a water leak in the basement soaked the back panel. It would let out an impressive amount of magic smoke when plugged in. Fortunately, seems the water only really got into the IEC inlet and destroyed the EMI filter, as I haven't been able to see any signs of damage anywhere else (and it wasn't powered on when this happened). Lots of melted plastic and even a hole straight inside the filter: Corcom still make the same right-angle inlet/filter to fit the narrow space in the back of the chassis, so fingers crossed that once I install a replacement, it'll power back up like normal.1 point

-

Wow, good luck up there and look out for the air karens. You know they're coming next.1 point

-

1 point

-

Man, it's been a long time but I still have most of his stuff on vinyl. Back in the eighties, CBC Radio had a late night program called Brave New Waves that introduced this country boy to Foetus , Nurse with Wound, Psychic TV, Current 93 and on and on. Good times, for sure.1 point

-

Oh no, I would not bother recording a band with a drummer. Who wants those crazy fuckers around?1 point

-

1 point

-

1 point

-

I have been doing steaks and even tri-tip this way. Take it to about 20 degrees below your desired temp, wrap and remove, crank to searing temp, unwrap and sear until 5 degrees below desired temp. Remove and let rest as it will continue to cook. Serve1 point

-

Hi all, New guy again. I received the ES Labs Sigma with 404 transducers yesterday. So, grain of salt and all... They're lovely. They sound great on chamber music, and the sense of space is really nice. Significantly darker sounding than the L700. Also a bit rounder the the 007 MK2. Meaning, I think they either have a dip around 6K or a boost around 300Hz (or both). My biggest issue is efficiency. Orchestral crescendos produce significant clipping. I just can't play them loud enough compared to the L700 or 007 (which will also clip on occasion compared to the L700). Now, I'm new to Stax, so I'm not sure if I'm hearing the KGST go into clipping or the drivers are reaching their excursion limits. Maybe when I get my SRD-7 from Birgir, and hook them up to my Bryston monoblocks, I'll be able to get more SPL out of them. Time will tell.1 point

-

Reverse sear is definitely my new favorite way to do steak, and I like the idea of smoking to temp. I'll have to try that.1 point

-

1 point

-

My friend rested the day before yesterday. 59 years. Many other clubs showed their respects. A great person, kind, loving, always taking care of the weakest boys in the cycling peloton Our club will place a commemorative plaque on one of his favorite routes.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Delta doesn't fill middle seats so most rows had two people in them, and then there were a few empty rows around the wing exit rows. I had a full row to myself after moving up one row. I don't think the bars are open here...0 points

-

I'm taking my first airline flight since early March, and my airline luck has picked up where it left off. We took off almost right on time even though the flight crew was late to arrive. After flying for a few minutes the captain came on to say that the cabin could not be pressurized properly so we had to turn around. Now back on the ground and not sure if or when we can get going again. My layover is only 90 min and the next/last flight of the day to my destination is five hours later. Fucking airlines are still fucking up.0 points