Leaderboard

Popular Content

Showing content with the highest reputation on 04/01/2021 in Posts

-

9 points

-

4 points

-

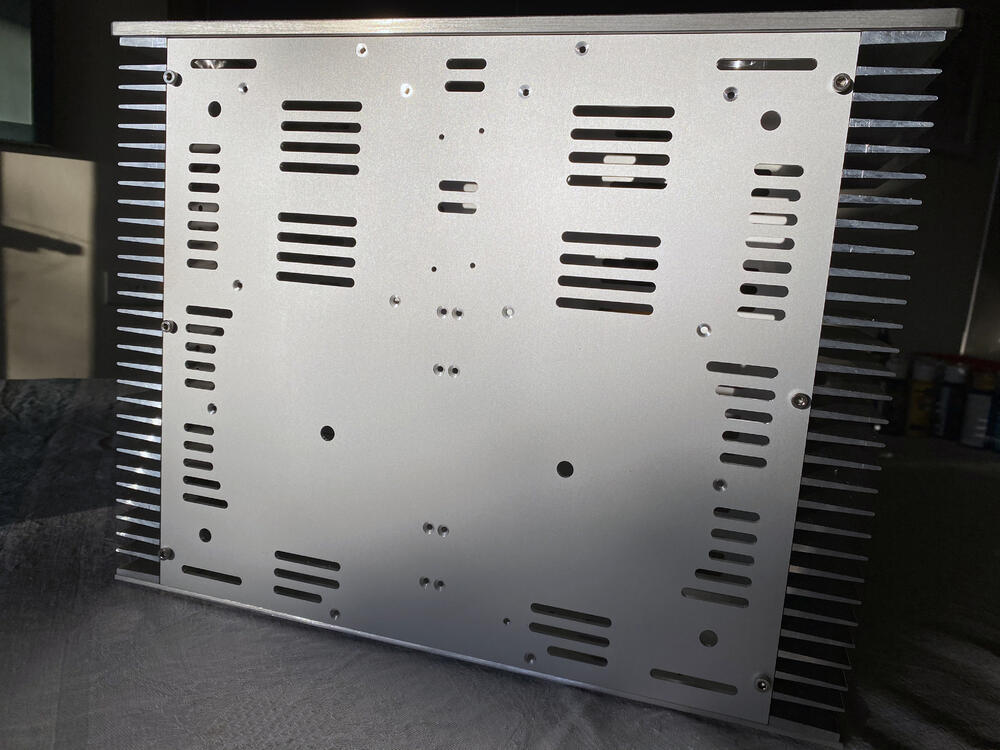

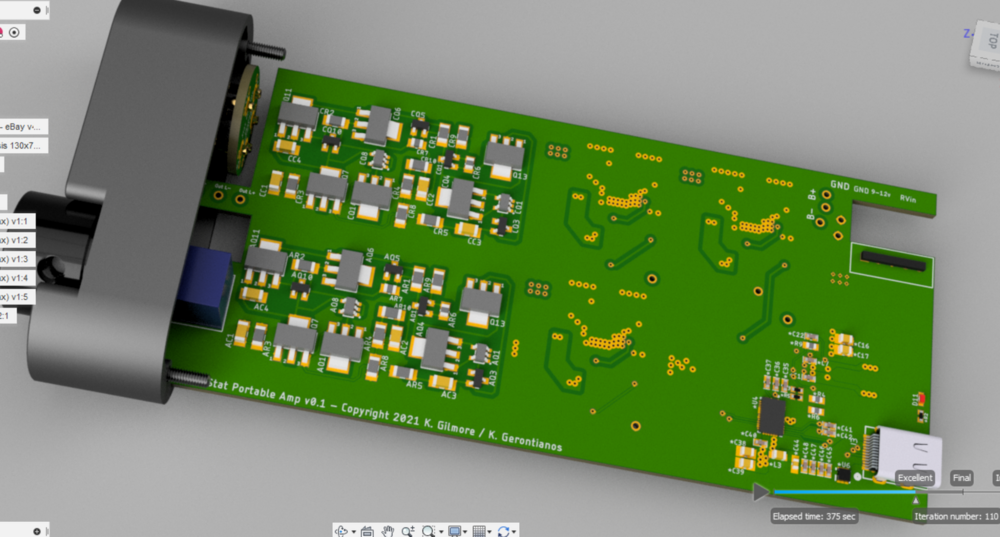

Making some progress on the main amp board. It will have a USB-C PD port so it will accept 5, 9, 15 & 20 volts. I think a 20W charger should be enough, but I'll have to test that once the prototype is built. This is getting pretty dense. We'll have to have this partially assembled since the PD stuff is going to be a pain to do. There are 0402 components in addition to some of the larger chips with multiple pads under the chips. This has 4 amp channels, +/-300V supplies, 580V bias and now the PD stuff with boost / buck on the input and includes the battery charging components as well. Looking at using 3S lithium batteries. The board is currently 161mm x 61mm and I think I can fit what's left. There's still more to do, but here's where I'm at...3 points

-

A question for the Festool geniusseses I am going to mount the legs to the stretchers with dominoes, but I want the stretchers set back from the edge of the legs. 1/8” on the side and 1/4” on the front/back. Is there a repeatable way to do this? Never mind, found a Sedge video where he does 10mm offset and it is good enough.3 points

-

3 points

-

2 points

-

Michael, Check out the Rossman group videos on YouTube. He does a review of some hot air stations. He likes the Quick, but I believe he has one from Atten which is cheaper and performs just as well.2 points

-

2 points

-

Happy Birthday Doug! You have been such an inspiration to me over this past year. Look at my latest. I call it Homage to Doug.2 points

-

2 points

-

1 point

-

1 point

-

if you are referring to the high voltage lines on a diy t2 - those psus use two 450V caps in series for double the voltage rating of one cap at the cost of halving the capacitance (except for rails bellow 300VDC output). The golden reference does not use series capacitors like this. the golden reference uses a single input and output cap per rail. So the each cap has to withstand the full voltage by itself. if the output is 400V then 450V is ok for the output cap giving you 10% or so margin. the input cap will need to have a higher rating than this because all regulated power supplies require more input voltage than they provide output voltage so they can maintain regulation. I think, if I remember correctly, the golden reference is about 330VAC input for 400VDC output. 330VAC once rectified through the diode bridge will give 330* squareroot(2) ~ 466Vpeak. Plus main voltage can vary, plus transformers can vary so to be safe you would want at least a 500V input cap. You may be able to get away with a lower input VAC if the golden reference can maintain regulation and your line voltage does not sag. Also consider that the higher the current draw the lower the output of a transformer and visa versa. So if you over spec your transformers current capacity the output voltages can be higher than you expect...1 point

-

1 point

-

1 point

-

1 point

-

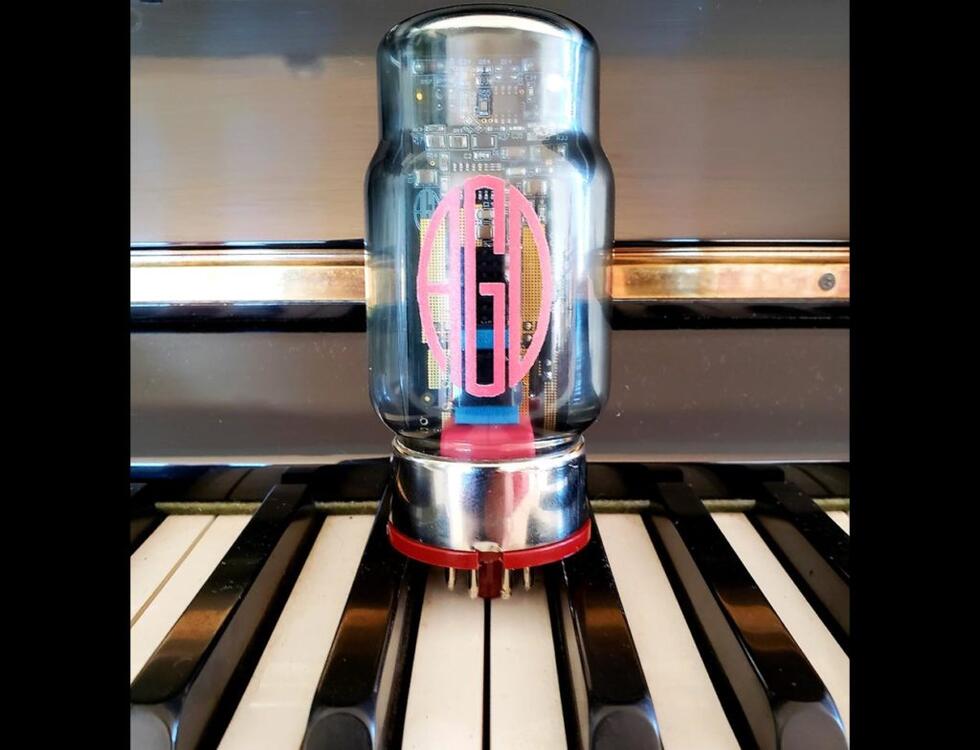

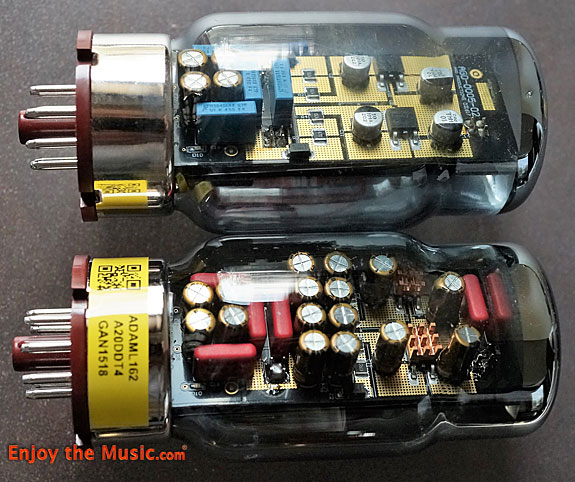

AGD The Audion Mk 2 "GaNTube" amp. Clever ( ? ) use of GaN amp board inside a tube structure, with up to 170 watts into 4 ohms. Neat design, and I have a pair of mono GaN amps ($1500/pr) that likely sound just as good; so not sure it's worth the money to have it look like a tube amp..... Third picture is the old vs. new version of the GaNTube.1 point

-

the quick 861dw comes highly recommended its also useful for drying out pcbs after ultrasonic cleaning, removing surface mount components, heat shrink etc.1 point

-

To date I've soldered all the SMD applications using a fine-tip soldering iron and a fine tip tweezer. I also find using very small gauge solder is key - I use .02"/3mm diameter solder from Kester with 2% silver and it works great. You can get a small tube of this solder from Mouser offered by NTE. I can try dig out the part number if you are interested. I want to experiment with a hot air station but have not done so yet. Mostly because I could to decide how much to spend and which one to get. Even the very basic one from the trusted brand (JBC, Hakko, etc.) costs an arm and a leg.1 point

-

I use an oven (when it’s not too cold outside) and a hot air station during the winter. I agree that you need to set the air velocity way down. I do keep a tweezers handy in case something moves or tombstones, but I generally don’t need it. Try to have the air gun directly over and perpendicular to the parts. I move it around in small circular motions anywhere from 12mm - 25mm above the parts. It’s very important that the parts are somewhat centered in the pads. For 0603 and down, I use a loop while I’m placing the parts. Once you get the hang of it, it’s a very fast way of soldering.1 point

-

1 point

-

1 point

-

I found a pretty cool youtube creator who's channel is called Game Maker's Toolkit. He has some very interesting videos. I really enjoyed this one. I've always wondered why it is that I am put off by some games that other people love. This video talks about one mechanic in a lot games that just constantly frustrates me, namely, navigation. I don't know what it is about my brain, but if a game drops me in an open world and expects me to explore, be curious, and make a mental map of the layout as I go I get frustrated and quit pretty quickly thereafter. It is a mechanic some people love, but I really do not. It is interesting to think about how many games are built around navigation as a core draw. Many of the Zelda games, Souls-borne, etc. I don't think I like any of them. Prior to watching this video I would not have been able to articulate why. Cool stuff.1 point

-

1 point

-

HBD Dougie Fresh! I shall have some county donuts in your honour (sorry)1 point

-

Found it (not the cartridge, but what it was). It was an Apature. I'm guessing it was a KOCE. Reading up on them, supposedly Ortofon made them or had something to do with them. I remember liking it though. Sorry to quote my own post, but somehow just ran across the brand of the cartridge today.1 point

-

1 point

-

1 point

-

1 point

-

I always do smd soldering with fin tip solder iron and after a long time of practicing I feel quite comfortable with that. I’ve tested with hot air station and with proper amount of solder paste on the pads and when using low air flow I managed to solder without components blowing away. And it’s a nice feeling seeing a component nicely aligning up on its pads. But I prefer the soldering iron technique. Me and solder paste don’t mix well. After a while the whole table is a mess and I even have solder paste on my nose. With some practice I’m sure everyone can do smd soldering, but it can be very frustrating initially.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Happy birthday Doug! Some guys would wish for titties and beer, but I hope your day is full of kitties and (woodworking) gear! Cheers!1 point

-

1 point

-

1 point

-

1 point

-

I did some experimentation and found that low airflow and fairly high air temp worked best for me. I have a quick 861dw hot air station. I set the airflow to 5 out of 120 and set to 360C (the temperature will depend on your solder paste melting point). I hold the hot air nozzle with one hand and with the other I use tweezers to keep the smd part in place. If you do not hold the part in place almost any airflow will send components into low earth orbit. The tweezers I use are curved on the end which makes it easier to place components, keep your hands away from the heat and easier to see what's going on.1 point

-

1 point

-

Had some double-spicied chicken ramen from Sushi Jin's, it was delicious. Don't have room for the sushi, so leaving it in the fridge overnight. (I know, I should've eaten the sushi and refrigerated the ramen. Was hungry, wasn't thinking straight.)1 point

-

Thanks Alan. I'll give that a read. Interesting that it's from back in the day Here's a rendering of what the amp will look like. It will be about 70 x 150 x 24 mm. We're looking at using USB-C PD so we'll be able to run off of most chargers (at least 20W). Power input will have a boost/buck converter so it could run off of 5/9/15/20V chargers. Still some work ahead, but we think we'll be able to fit a DAC in as well.1 point

-

1 point

-

This post from Søren in the Circlotron thread is useful for testing a GRHV. EDIT: Per Soren, note that these instructions are for the Circlotron, so differ from a GRHV somewhat. For the initial check, I was getting 0.5mA; Soren said maybe 1mA. For the 2nd CCS, I was getting 1.4mA. These will depend upon your particular DN2540s. The current limiting CSS he notes is not applicable on the GRHV, so ignore that portion. My boards both worked fine. The paralleling of the gain resistors (2 x 390K for a 400V GRHV) worked quite well. I put a 100K in parallel with the series string for a regulated output of ~55Vdc. Make sure you use a variac for this to limit the input voltage.1 point

.thumb.jpg.c68f36a145f58d68a58034aa908867da.jpg)